Methods for preparing transition joint of different metal materials

A metal material and transition joint technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor air tightness and low joint reliability, and achieve high joint reliability, low heating temperature, and good vacuum. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

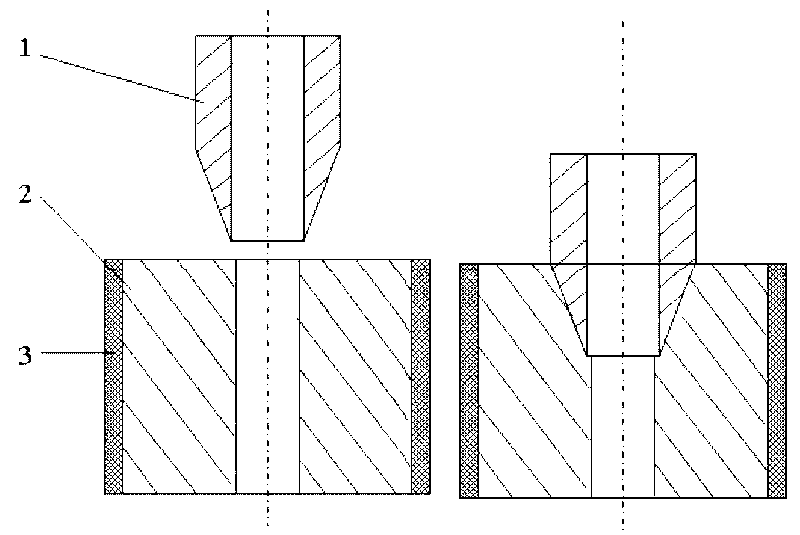

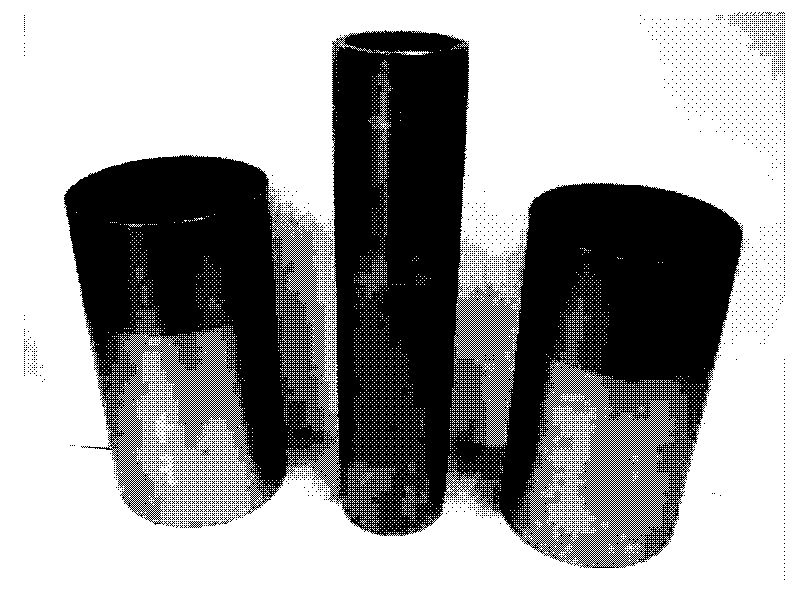

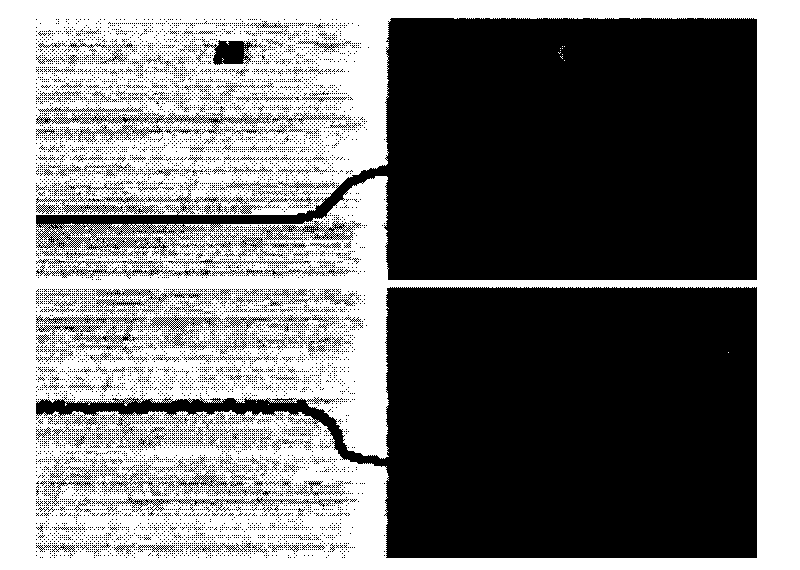

[0010] Specific Embodiment 1: The method for preparing transition joints of dissimilar metal materials in this embodiment is carried out according to the following steps: 1. Process the end of metal material A into a taper of 10°-50°, and the height of the taper surface is 4-70mm, and then grind it Make the surface finish of metal material A as 2. Clean metal material A and metal material B polished in step 1 with acetone to remove oil, heat metal material A to 100-350°C and keep it warm for 10-180min, heat metal material B to 300-580°C and keep it warm for 10 minutes ~180min; 3. Connect the heat-preserved metal material A and metal material B under the condition of a pressure of 10-1000kN by hot pressing, and press all the polished conical surface of the metal material A into the inner cavity of the metal material B to obtain a joint; 4. Heat the joint obtained in step 3 for 0-600 minutes at 400-600°C to obtain a transition joint of dissimilar metal materials; wherein the me...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, the end of the metal material A is processed into a taper of 20° to 40°, and it is polished so that the surface finish of the metal material A is Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, the end of the metal material A is processed into a taper of 20° to 40°, and it is polished so that the surface finish of the metal material A is Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leak rate | aaaaa | aaaaa |

| Leak rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com