Separation mechanism of on-board equipment

A technology for separating mechanisms and equipment, which is applied in the satellite and aerospace fields, can solve problems such as poor product versatility, poor tape versatility, complex system composition, etc., and achieve the effects of reducing the difficulty of machining, large mechanism bearing capacity, and flexible installation positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is specifically described by using a typical single set of on-board equipment separation mechanism. As for the specific selection of several sets of compression and release mechanisms in the specific application process, it should be determined according to the shape and requirements of the target load.

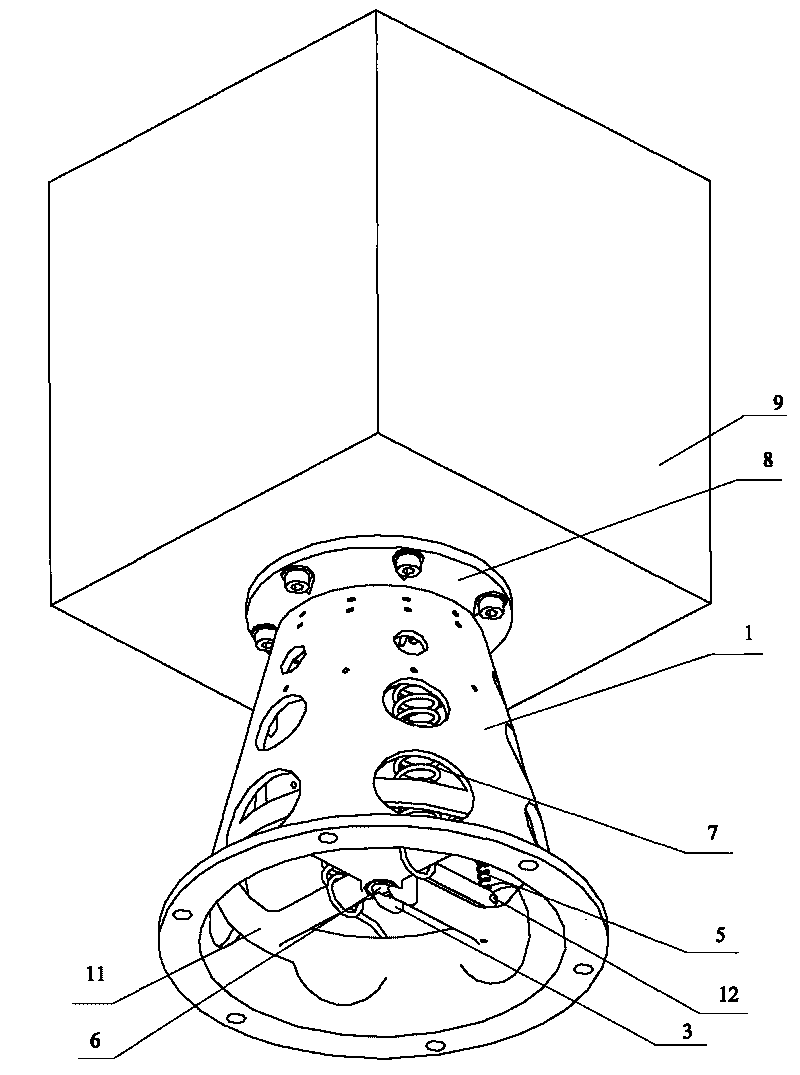

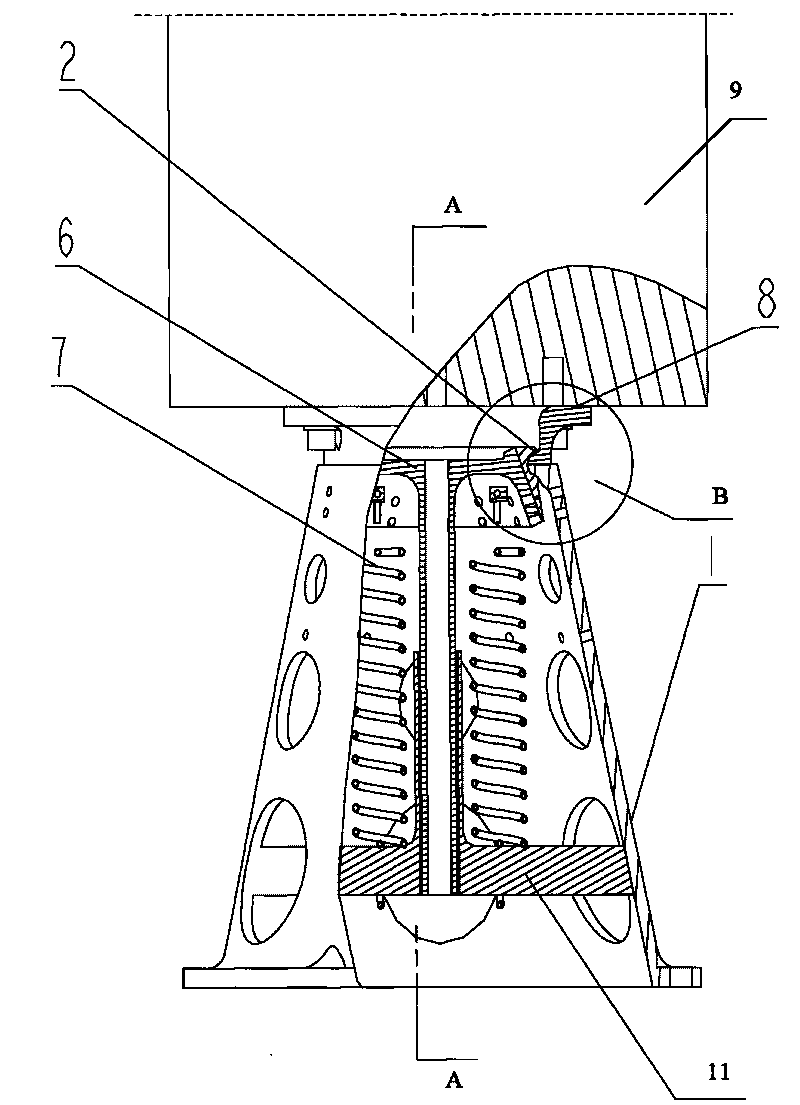

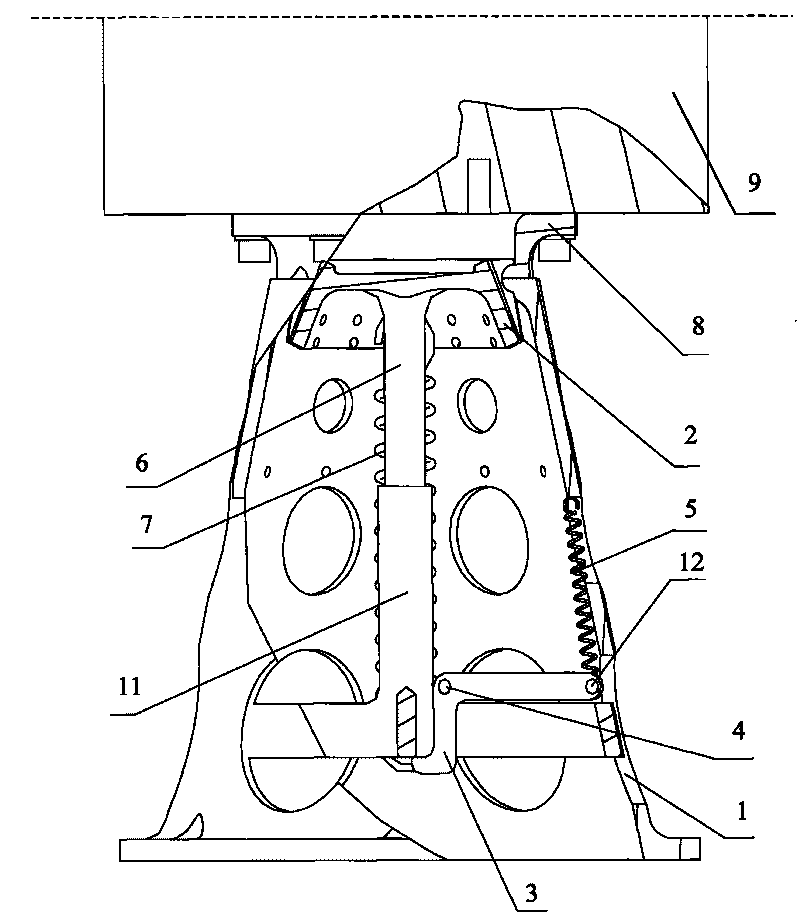

[0042] figure 1 It is a perspective view during the implementation of the present invention, figure 1 The square equipment in the middle and upper part is the simulated target load 9, and the lower structure of the target load 9 is the on-board equipment separation mechanism of the present invention.

[0043] Such as Figure 2-5As shown, the present invention includes an installation base body 1, several pressing clamp blocks 2, a connecting flange 8, a pressing and releasing mechanism and an unlocking device. The compression and release mechanism includes a connecting shaft 6 and a connecting spring 7, and the unlocking device includes a dead b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com