Construction method for back cable-balancing single-side cantilever concreted beam bodies of slant-legged rigid frame bridges

A construction method and rigid-frame bridge technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as high site requirements, high requirements, and impact on traffic, and achieve equipment and time saving, significant economic benefits, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

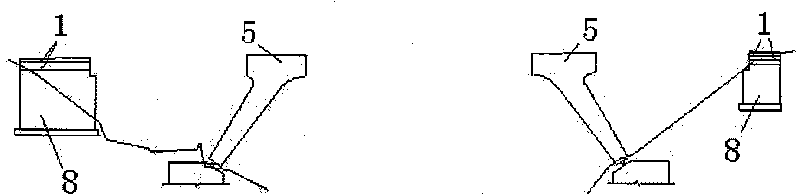

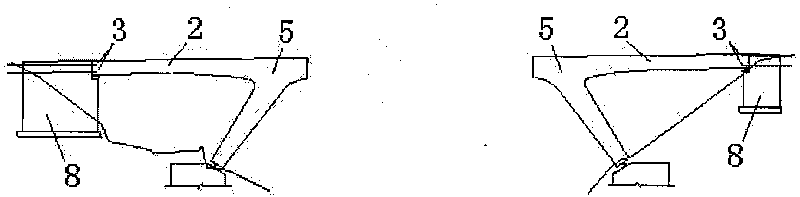

[0033] Embodiment 1: construction of side span 2

[0034] Such as figure 1 , figure 2 , on the abutment 8 on both sides of the bridge, the corresponding side span 2 pre-embeds the corrugated pipe 1 and the anchor backing plate, or reserves the pipe fittings that can penetrate the balance back cable 3, and the abutment 8 on both sides of the bridge, the inclined leg foundation After the construction of , oblique legs and No. 0 block 5 is completed, military piers and military beams are used as supports for installing side spans 2 to carry out cast-in-place construction of side spans 2 on both sides.

[0035] The construction procedure is:

[0036] 1.1. Ground treatment. The military pier foundations are all made of concrete foundations and placed on stable rock foundations to ensure that the foundations do not settle.

[0037] 1.2. Erection of military piers and erection of military beams.

[0038] 1.3. Bracket preload. Put the bottom mold on the military beam, and stack...

Embodiment 2

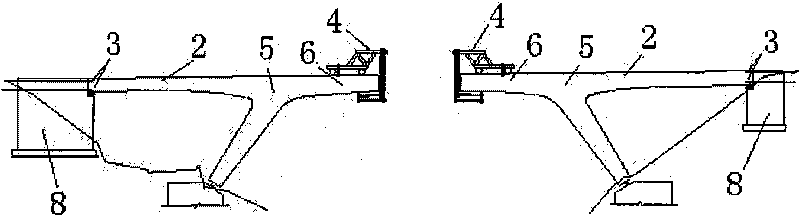

[0051] Example 2: Construction of mid-span 6 and mid-span closing section 7

[0052] see image 3 , Figure 4 , after the side span 2 and the abutment body of the abutment 1 are temporarily locked, the hanging basket 4 can be installed, and the cantilever pouring of the mid-span 6 can be carried out, that is, the hanging basket 4 is used to cantilever from the oblique leg and No. 0 block 5 to the mid-span pouring in sections to form the mid-span 6 until the mid-span 6 is closed in the middle of the span. The pouring process of the mid-span 6 is as follows: the bottom formwork and the outer formwork are installed on the beam section corresponding to the mid-span 6 on the hanging basket 4, the inner formwork is placed on the top surface of the bottom plate, and then concrete is poured, tensioned and grouted.

[0053] 2.1. The process of hanging basket construction

[0054] Hoisting hanging basket 4 and bottom formwork platform, installing bottom formwork → hoisting outer form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com