Water-cooled chiller with on-line cleaning function of rubber ball shell-and-tube condenser front-end head box

A chiller and condenser technology, applied in the energy industry, heat exchanger shells, clean heat transfer devices, etc., can solve the problems of chiller surge, chiller operation impact, and large instantaneous changes in refrigerant condensation temperature, etc., to achieve The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] This embodiment is a preferred embodiment of the present invention, and other principles and basic structures that are the same as or similar to those of this embodiment fall within the protection scope of the present invention.

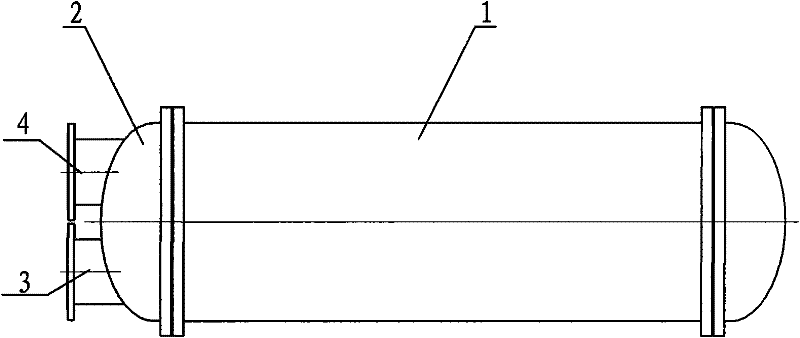

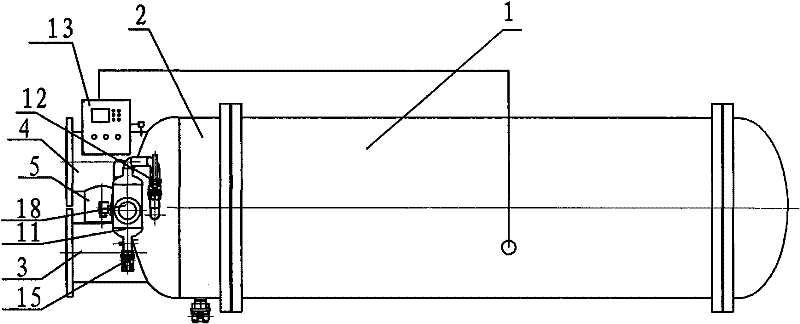

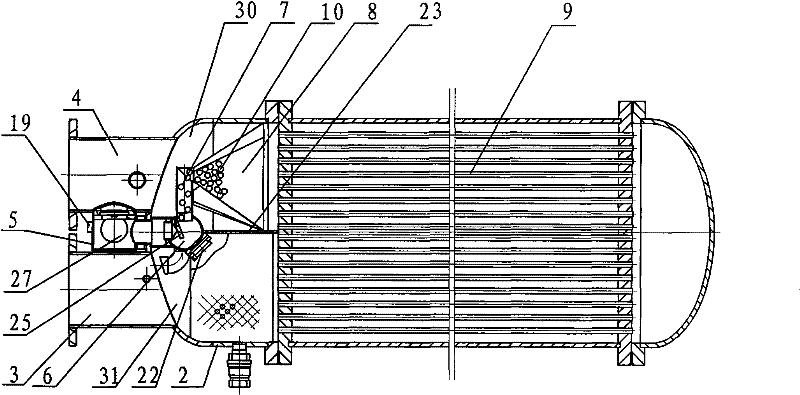

[0057] Please refer to the attached figure 2 , Attached Figure 7 And Figure 8 , The present invention is a two-process water-cooled water-cooled chiller shell-and-tube condenser front-end header tube box with automatic on-line cleaning function of rubber balls, which is used in combination with the condenser body 1. Please refer to the attached image 3 Attached Image 6 , The present invention is mainly a tube box for the front end of the condenser that is fixedly combined with the condenser body 1, which mainly includes a tube box 2 and a rubber ball automatic online cleaning device integrated with the tube box 2, and the middle position of the tube box 2 is fixed A partition plate 23 is welded, and the tube box 2 is divided into upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com