A small front-end head pipe box cleaning machine

A cleaning machine and pipe box technology, applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, heat exchange equipment, etc., can solve the problems of chiller operation shock, chiller surge, heat exchange efficiency reduction, etc., to achieve reliable operation , Compact structure, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

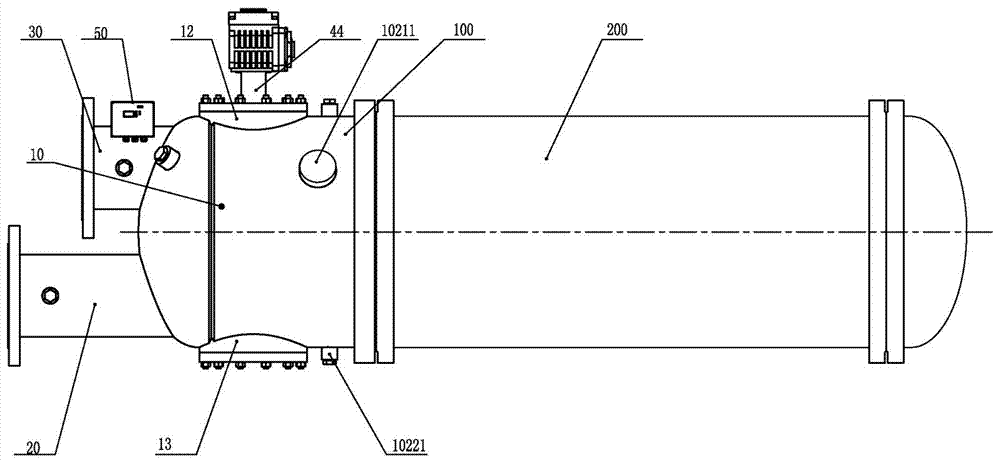

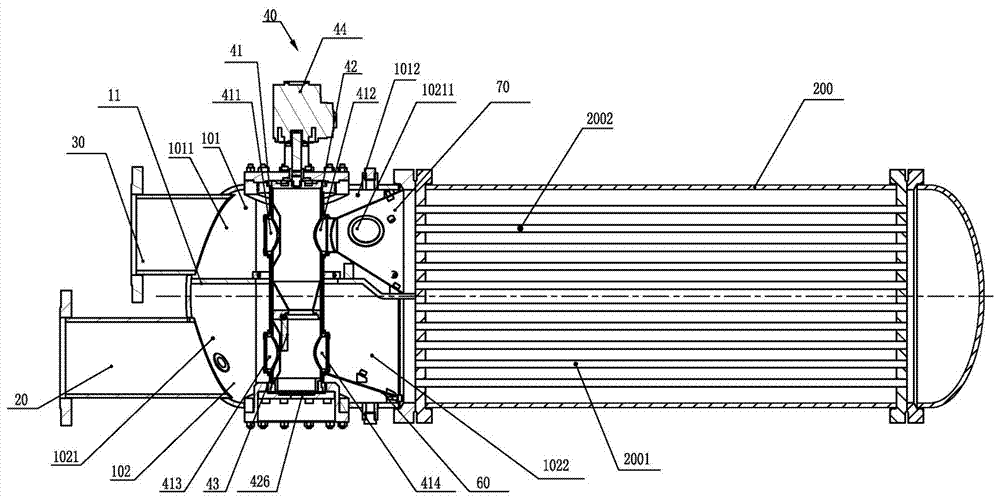

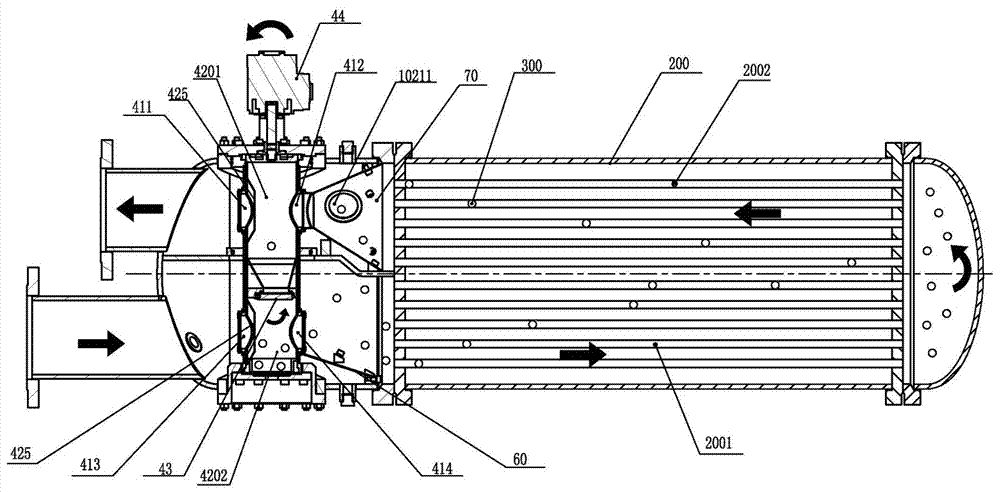

[0035] The small front-end head tube box cleaning machine 100 is suitable for small double-flow water-cooled chiller shell-and-tube condensers, small double-flow shell-and-tube flooded evaporators, and small double-pipe cooling water that runs through the tube and the temperature does not exceed 80°C. The process water-cooled shell-and-tube heat exchanger is now described in detail by taking the installation of the small front-end head tube box cleaning machine 100 on the small-scale double-process water-cooled chiller shell-and-tube condenser as an example. Figure 1 to Figure 18 , is a preferred embodiment of a small-sized front-end head pipe box cleaning machine 100 provided by the present invention. Such as Figure 1 to Figure 5 As shown, the small front-end head pipe box cleaning machine 100 is installed on the condenser 200, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com