Atmospheric dust sampling method and monitoring method

A dust and atmospheric technology, which is applied in the field of atmospheric dust sampling and monitoring, can solve the problems of reduced accuracy of atmospheric dust sampling and detection, high cost, and low degree of automation, and achieves low dust sampling and detection costs, convenient operation and use, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

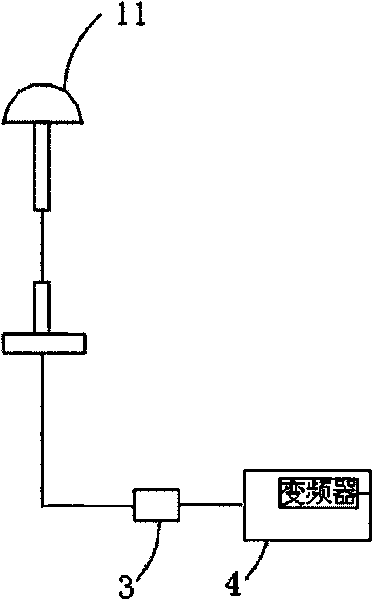

[0082] Such as figure 2 As shown, an atmospheric dust sampling device includes a cutter 11, a sampling pump 4 and a flow control unit.

[0083] The flow control unit includes a first-stage regulating device and a second-stage regulating device; the first-stage regulating device is a frequency converter, which is set on the sampling pump; the second-stage regulating device is a flow regulating valve 3 . The flow control unit adjusts the gas flow through the cutter in two stages: coarse adjustment and fine adjustment. First, the frequency converter is used to roughly adjust the flow rate, and the flow value is adjusted to the vicinity of the target flow value, and then the flow value is precisely adjusted to the target flow value by using the flow regulating valve 3 .

[0084] A frequency converter is added to the flow control, so that the sampling pump has multiple gears, and the fine-tuning is supplemented by a flow regulating valve, which is easy to control and saves energy...

Embodiment 2

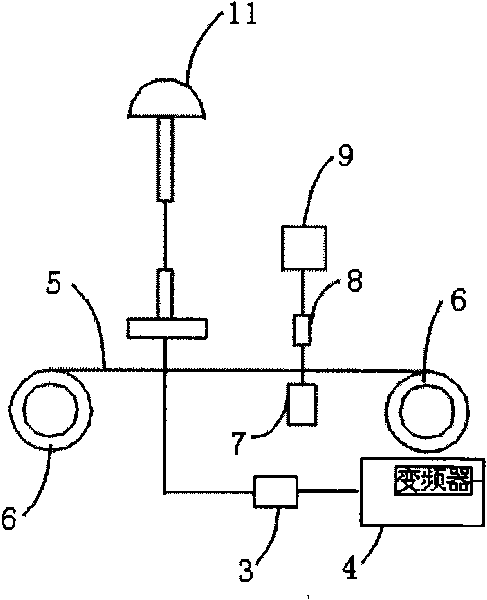

[0126] Such as Figure 4 Shown, a kind of atmospheric dust sampling device is different from embodiment 1:

[0127] The first-stage regulating device is a pressure protection flow path, and the pressure protection flow path is one or more paths, and each path adopts a solenoid valve or a pressure relief valve or a reverse check valve. In this embodiment, a three-way pressure relief valve is selected, respectively. It is pressure relief valve of No. 01, No. 02 and No. 03.

[0128] The flow control unit adjusts the gas flow through the nozzle in two stages: coarse adjustment and fine adjustment. When the gas flow required by the nozzle is relatively small, the pressure relief valve is opened in time as a coarse adjustment device to form a loop. The sampling pump only extracts a small amount of gas from the nozzle flow path. The gas flow is close to the target value, and then the flow value is adjusted through the fine-tuning regulating valve to the exact target flow value.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com