Brewing device of coffee powder bag

A brewing device, coffee powder technology, applied in beverage preparation devices, household utensils, applications, etc., can solve the problems of cleaning once, troublesome cleaning, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

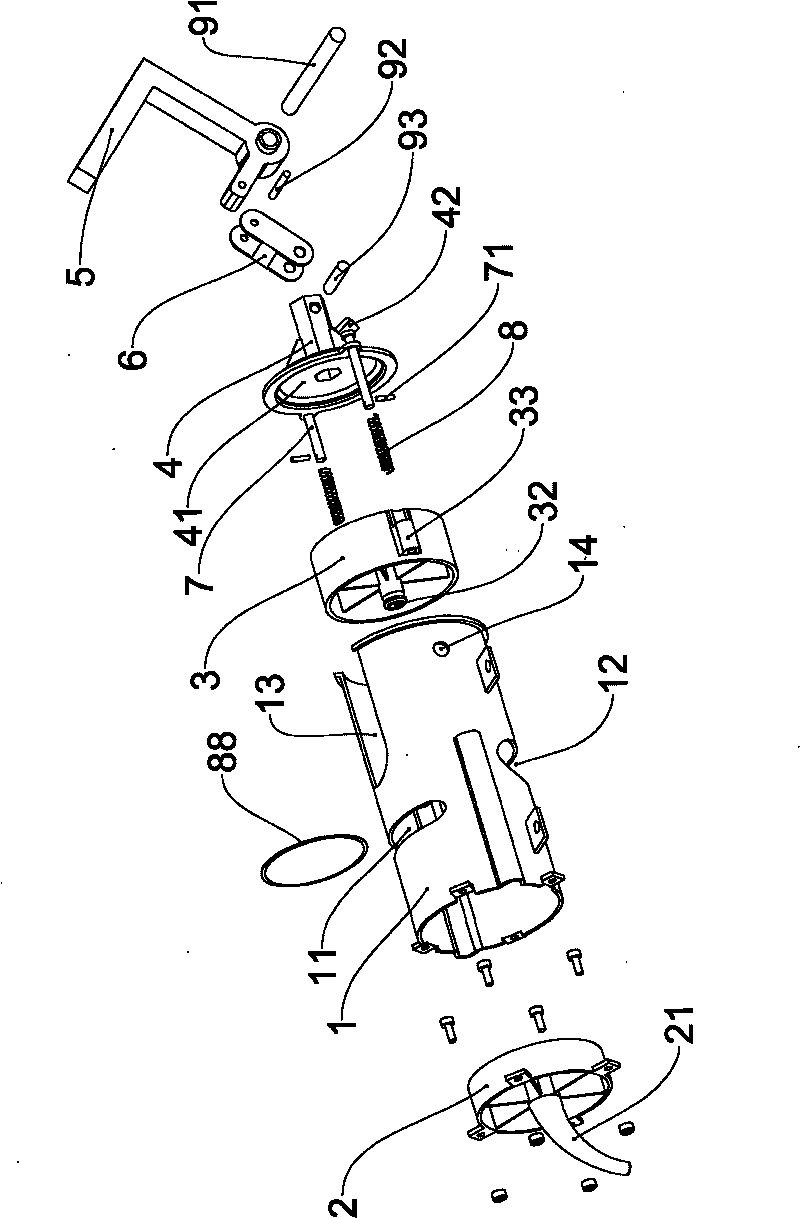

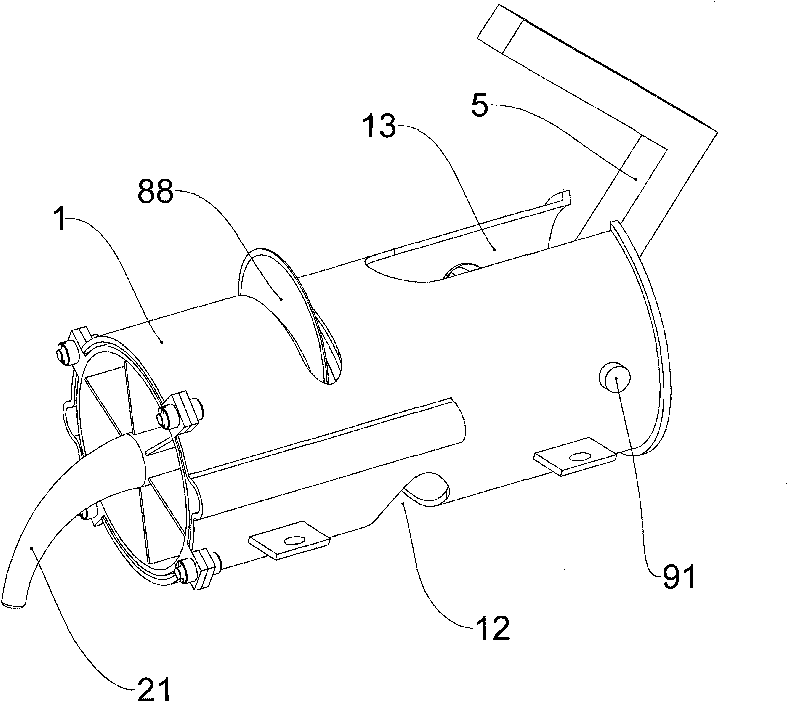

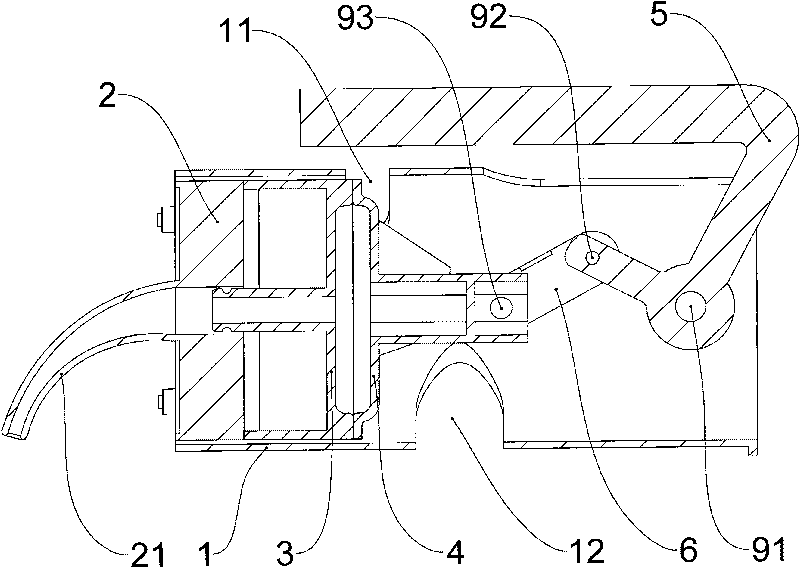

[0019] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention includes a cylinder body 1, a coffee outflow piece 2, a front brewing piece 3, a rear brewing piece 4, a rocker arm 5, and a connecting arm 6, and the coffee outflow piece 2 is fixed on the side of the cylinder body 1 At the front end, the coffee outflow member 2 includes a coffee spout 21, a feed hole 11 is provided above the middle of the cylinder body 1, and a discharge hole 12 is provided below, and a supply hole is provided above the rear end of the cylinder body 1. The rocker arm 5 rotates to give way to the slot 13, the feed hole 11 and the discharge hole 12 are staggered by a certain distance in the axial direction, and the front brewing part 3 and the rear brewing part 4 are both located in the barrel 1 and is slidably connected with the barrel 1 in the axial direction, the rear end of the front brewing part 3 is provided with a front brewing chamber 31, and the front end is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com