Novel self-potential riding wheel supporting device of rotary cement kiln

A cement rotary kiln and supporting device technology, applied in rotary drum furnaces, furnace types, furnaces, etc., can solve the problems of heavy maintenance work, affecting the service life of tire belts and supporting rollers, complex structure, etc., to eliminate the phenomenon of deflection , The effect of eliminating the hollow phenomenon and the effective axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

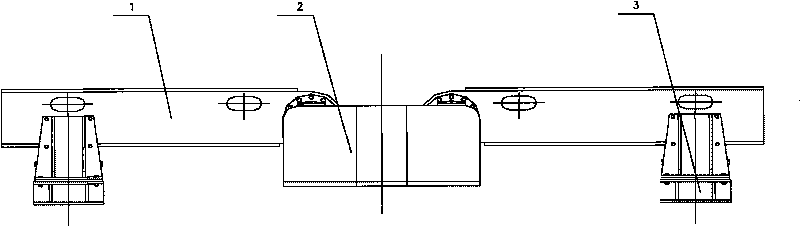

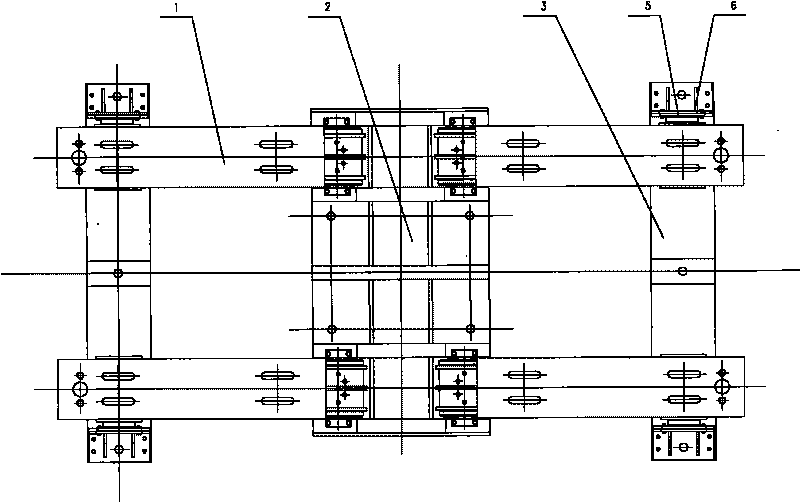

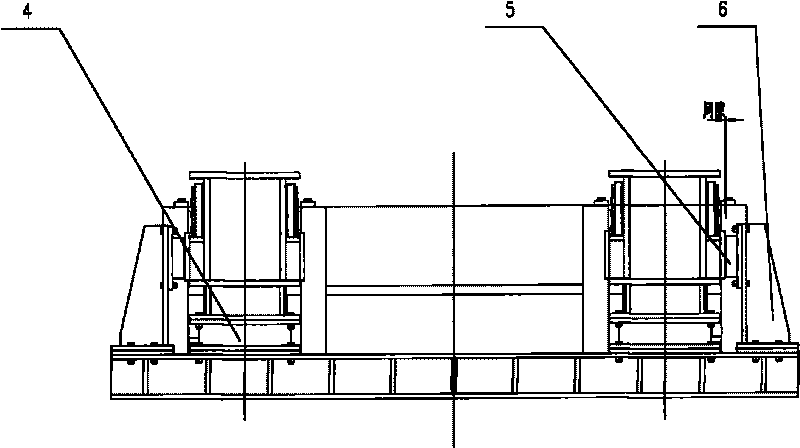

[0020] see figure 1 figure 2, image 3 , Figure 4 , Figure 5 and Image 6 , the four movable supports 1 are symmetrically arranged, one end of each movable support 1 is connected to the base 2 through the square body at both ends of the shaft 7, and the other end is supported on the radial elastic block 4, and the radial elastic block 4 is placed on the rubber On the seat 3, the head of the movable support 8 on the movable support 1 and the shaft 7 are connected by two thrust joint bearings 9 and one centripetal joint bearing 10, and the spherical centers of the three joint bearings all fall on the shaft 7. At the intersection of the transverse and longitudinal centerlines, the movable support 8 on the movable support 1 can do yaw movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com