Flow passage structure design method for anti-clogging drip irrigation emitter

A technology for structural design and sprinklers, applied in botany equipment and methods, instruments, calculations, etc., can solve problems such as eliminating blockage, difficult operation, and unspecific judgment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

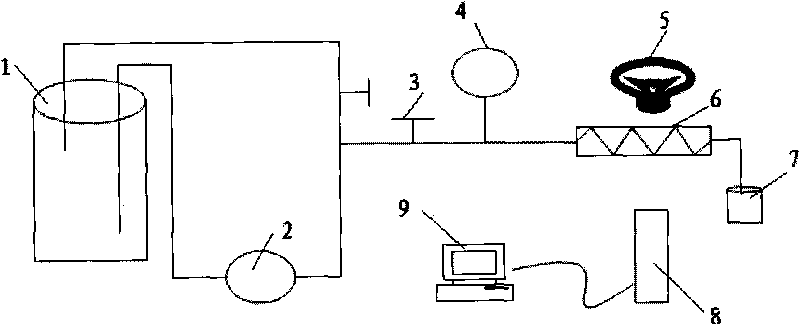

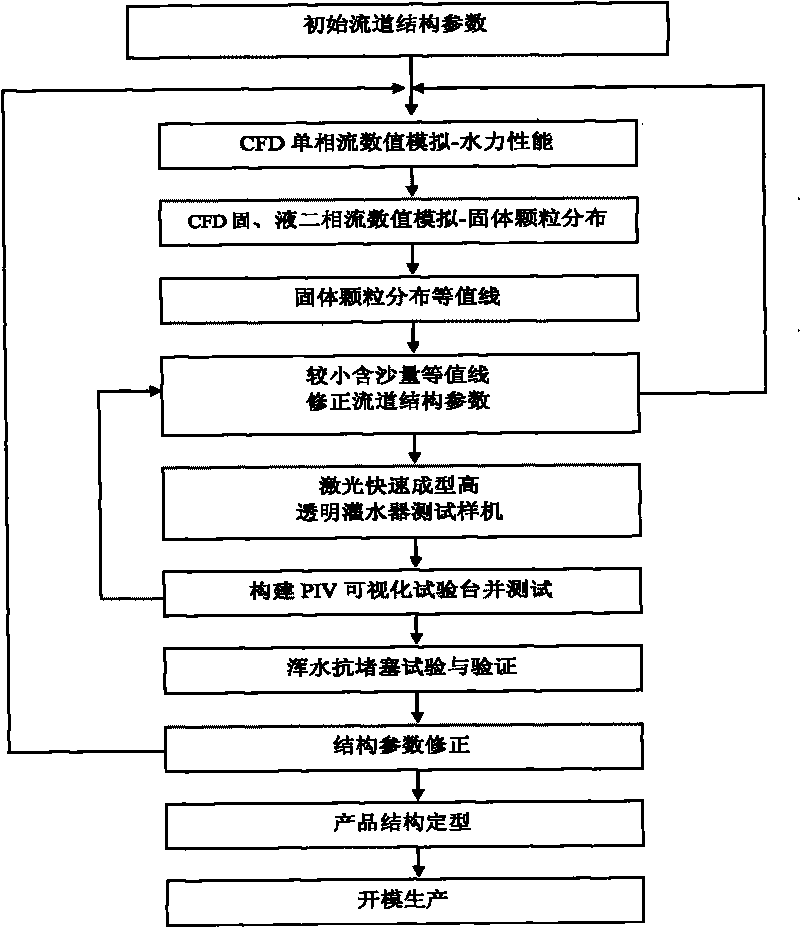

[0032] According to the technical solution of the present invention, an anti-clogging drip irrigation emitter flow channel structure design method specifically includes the following steps:

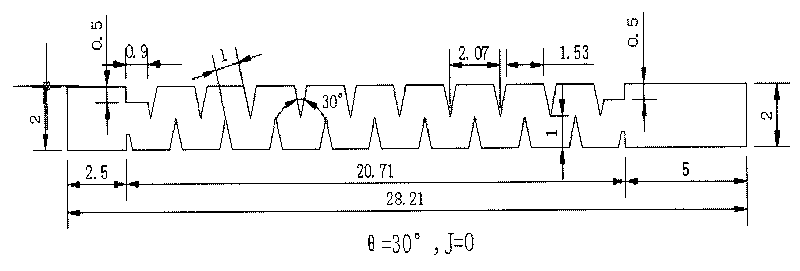

[0033] The first step is to determine the preliminary flow channel structure and parameters according to the design requirements. The flow channel structure is trapezoidal, rectangular or arc-toothed labyrinth structure. The width of the channel is between 0.6mm and 1.2mm, and the depth of the channel is 0.6mm. ~1.0mm, and according to the requirements of CFD numerical simulation software, select the following mathematical model

[0034] ∂ ∂ x k ( ρu k ∂ u ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com