Dual-drive speaker

A dual-driver, speaker technology, applied in the direction of sensors, electrical components, diaphragm structures, etc., can solve the problems of inability to meet the high power and high sound quality requirements of speakers, increased speaker distortion, and overall height thickness, etc., to reduce distortion, The effect of enhancing reliability and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

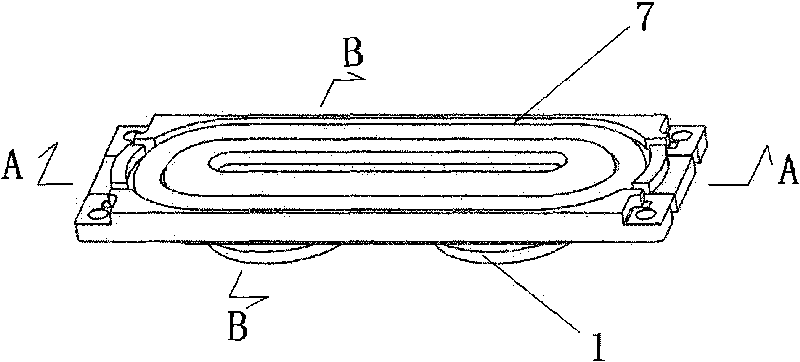

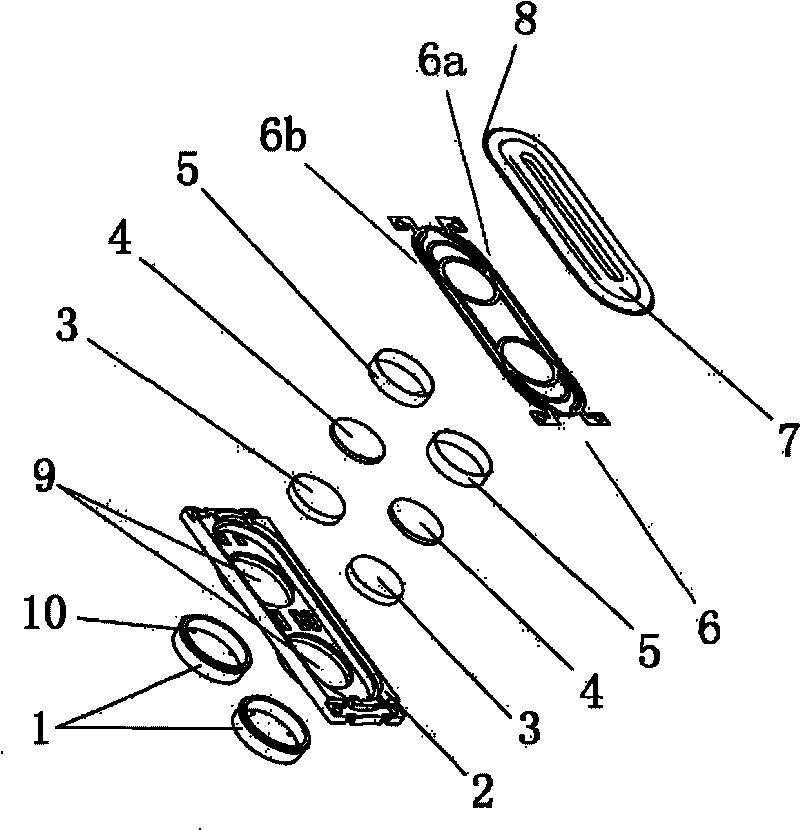

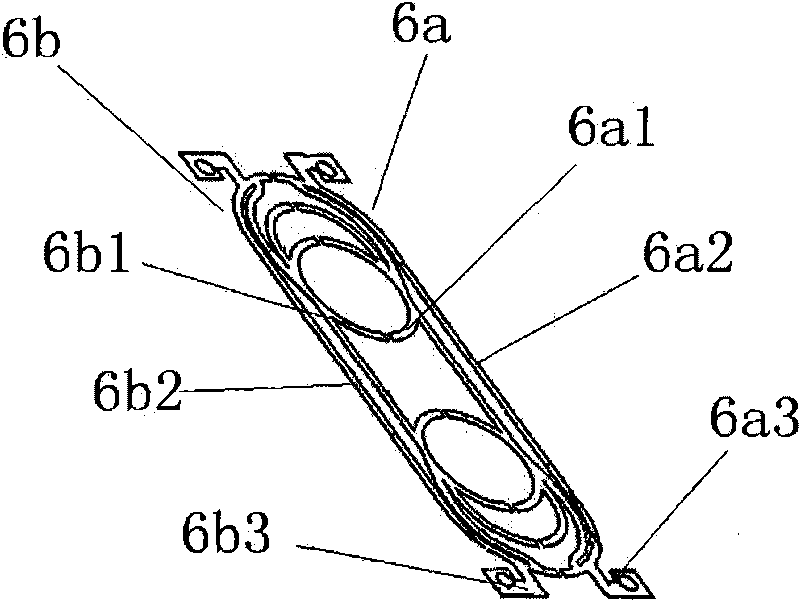

[0020] As shown in the figure, the present invention is mainly composed of U iron 1, basin frame 2, magnet 3, magnetic pole core 4, voice coil 5, positioning support piece 6 and film type sound cone 7, wherein, U iron 1, magnet 3, magnetic pole There are two cores 4 and two voice coils 5, one basin frame 2, one positioning support piece 6 and one film type sound cone 7.

[0021] Such as Figure 1 to Figure 6 As shown, two middle holes 9 are provided at both ends of the bottom of the basin frame 2, and a U-iron 1 is fixedly installed in each middle hole 9; a magnet 3 and a magnetic pole core 4 are installed in the U-iron 1, and the lower surface of the magnet 3 is connected to the U-iron 1. The inner surface of the bottom is closely connected, and the upper surface of the magnet 3 is closely connected with the magnetic pole core 4. There is a certain magnetic g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com