Device for analyzing and sieving liquid drops based on integrative sampling probe of chip

A screening device and probe technology, applied in sampling devices and other directions, can solve the problems of time-consuming and laborious, and increase the difficulty of microfluidic manipulation, and achieve the effect of reducing the difficulty of manipulation and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

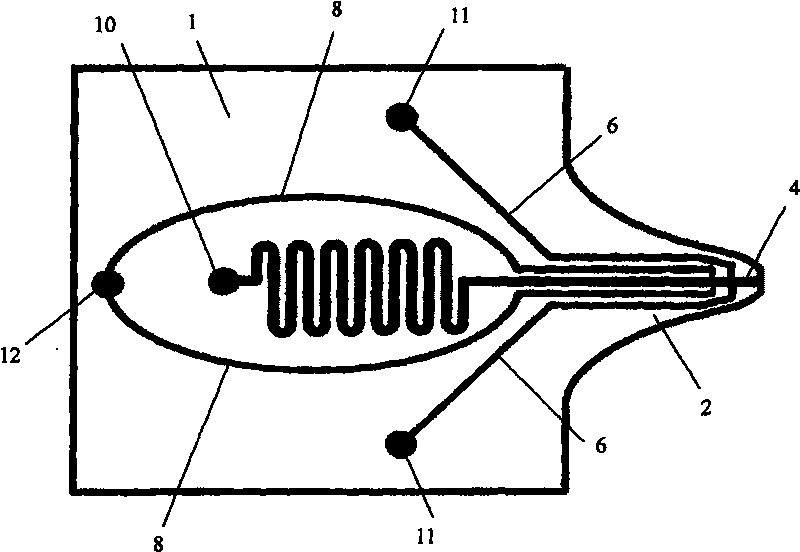

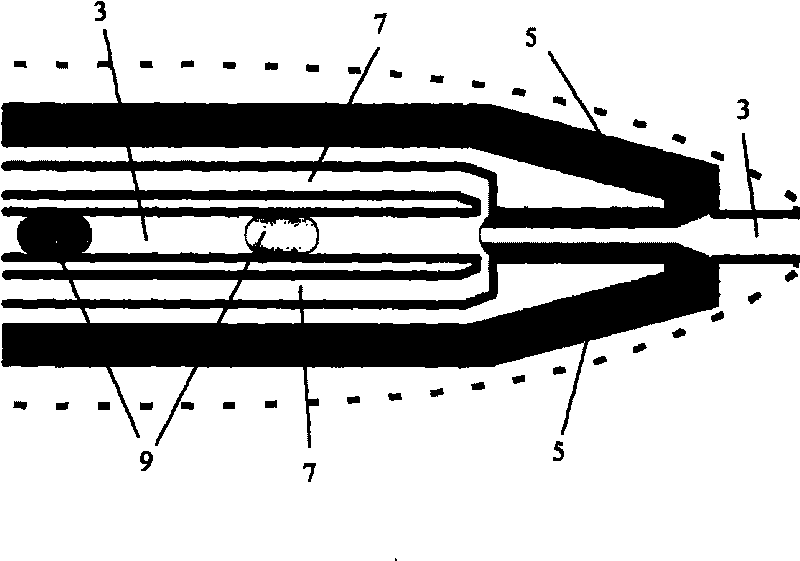

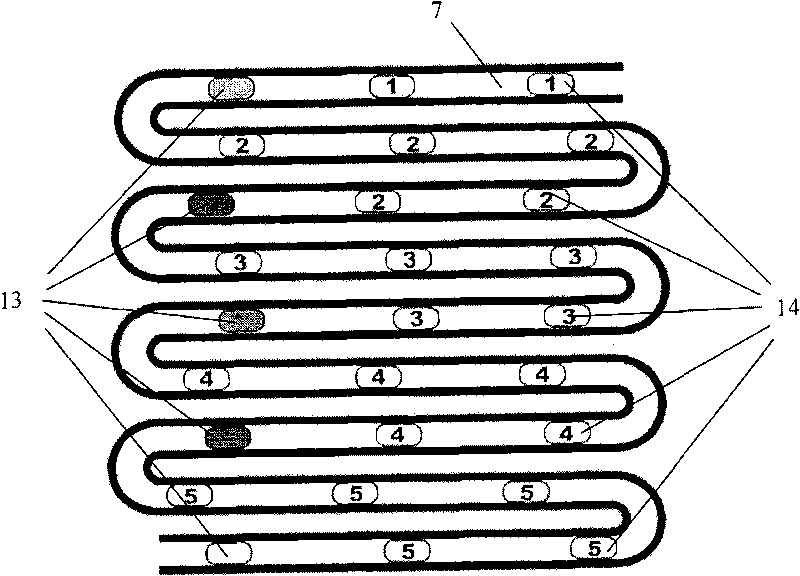

[0036] figure 1 It is a schematic top view of a droplet analysis and screening device based on a chip integrated sampling probe established according to the present invention. An integrated sampling probe 2 is processed on the microchip 1, and the sampling probe 2 integrates a sampling channel 4, two reagent channels 6, and a carrier liquid channel 8, so that it has the functions of sample introduction, quantitative addition of reagents, and liquid generation. The function of the drop reactor.

[0037]Before the droplet analysis and screening device is used, all microchannels in the microchip 1 and the outer wall surfaces of the sampling probe 2 need to be treated with hydrophobic or hydrophilic treatment. Fill the channel of the chip with carrier solution. The syringe used to drive the carrier liquid is filled with the carrier liquid, and the syringe is connected to the inlet 12 of the carrier liquid channel 8 through a pump tube to provide positive pressure driving. The s...

Embodiment 2

[0042] Figure 5 It is a schematic top view of an integrated sampling probe according to yet another embodiment of the present invention. Different from Example 1, when the droplet reactor only needs one reagent to participate in the reaction, only one reagent channel 6 needs to be processed in the sampling probe 2, so that the screening sample and the reagent form a confluence and generate a droplet reaction device. This can further reduce the size of the sampling probe 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com