Active component array motherboard and manufacturing method thereof

A technology of active components and manufacturing methods, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and electrical solid-state devices, etc., can solve problems such as damage to lines or components, large electrode pad area of the test pad structure, etc., to improve the process. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

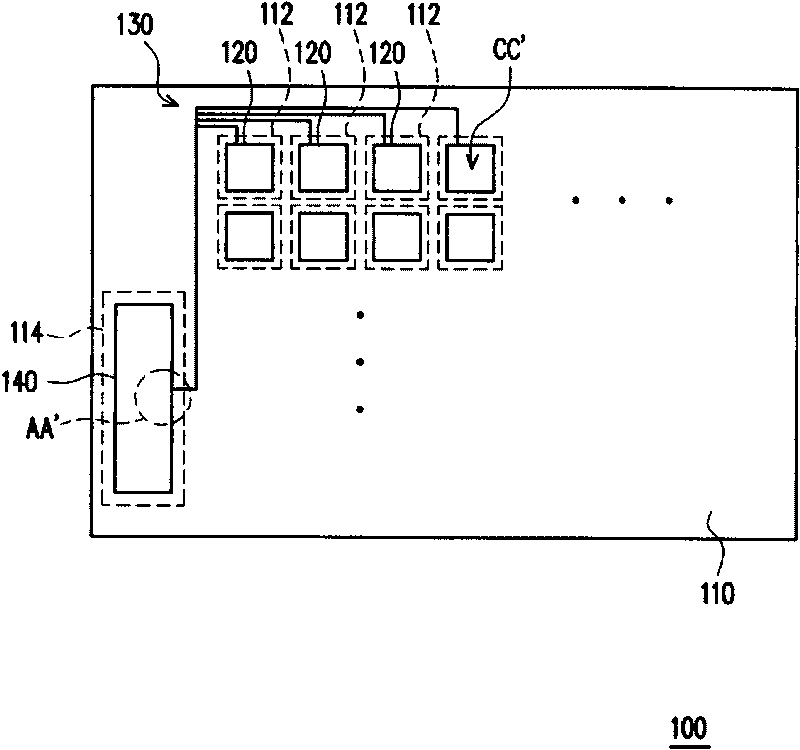

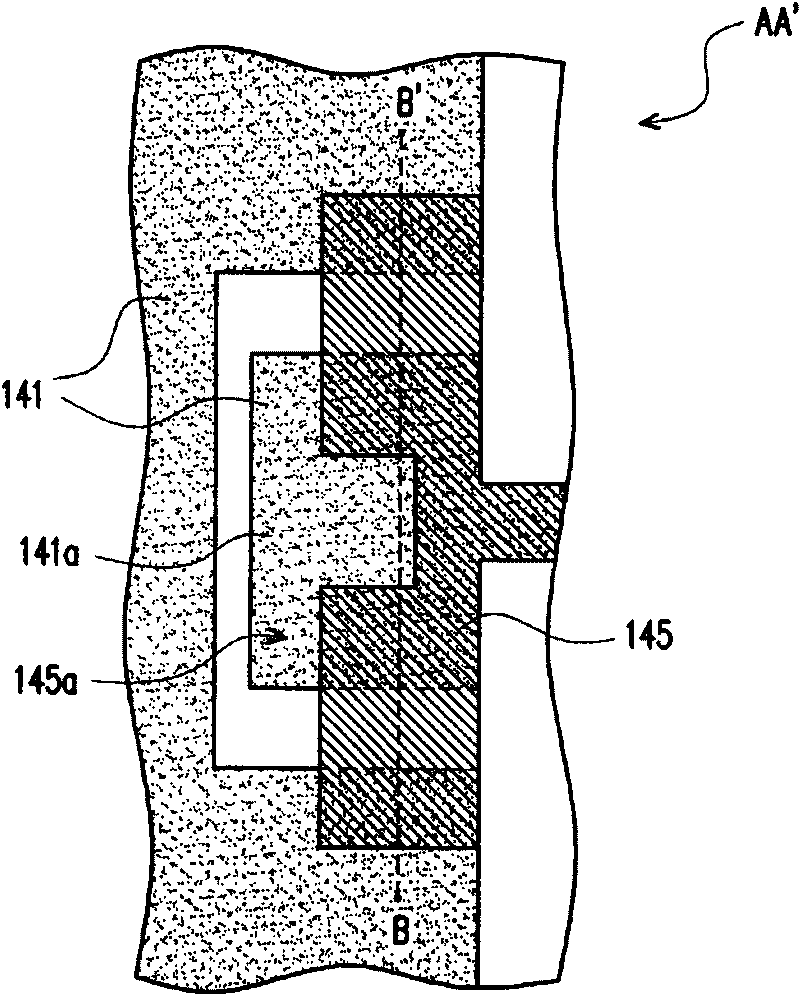

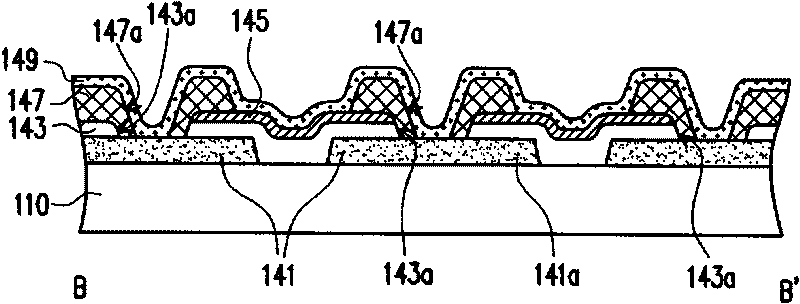

[0055]Generally speaking, because the electrode pad area of the test pad structure is too large, a large amount of electrostatic charge is often accumulated on the electrode pad during the photolithography process. However, excessive electrostatic charge will be introduced into the active device array due to electrostatic discharge effect (ESD Effect), which will damage the circuits or elements in the active device array. In view of this, the present invention proposes an active device array motherboard, the test pad structure of which has a plurality of first metal patterns (that is, the above-mentioned electrode pads) that are separated from each other and electrically connected, so as to effectively reduce the size of the original electrode pads. area, thereby reducing static charge accumulation and preventing electrostatic discharge effects. The structure and implementation of the active device array mother substrate of the present invention will be described in detail b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com