Compressed flexible cable conductor

A flexible cable and conductor technology, applied in conductors, non-insulated conductors, circuits, etc., can solve the problems of increasing the outer diameter and weight of the cable, limiting the use range of the cable, poor bending performance, etc., to reduce the material cost and move the performance. Good, good bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

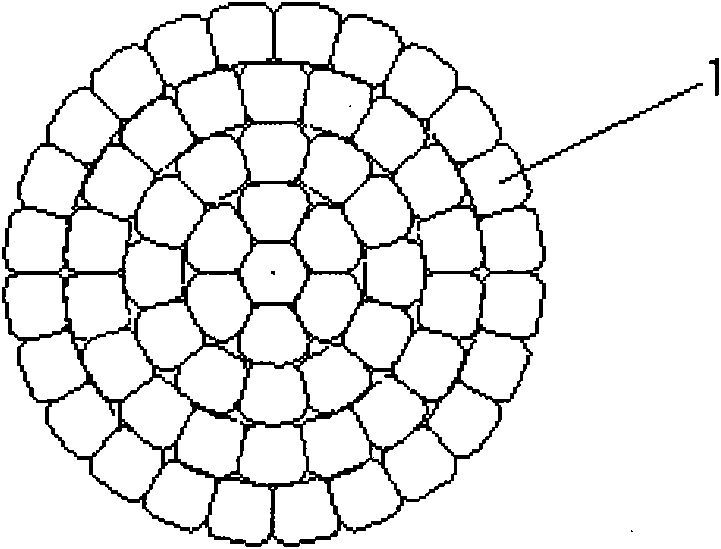

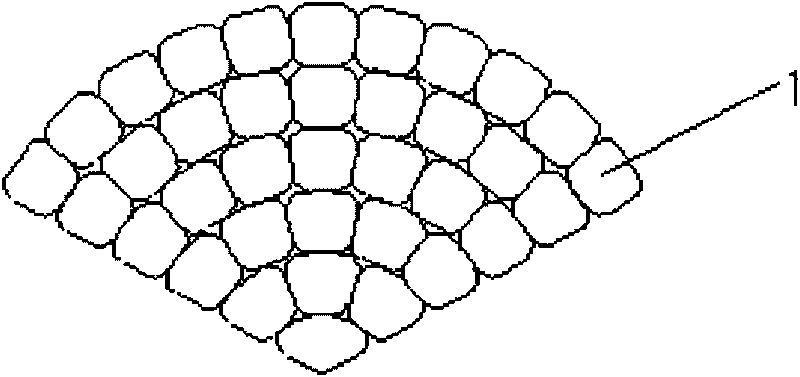

[0014] A compact flexible cable conductor, which consists of several copper conductors arranged in multiple layers into a certain shape and pressed together by a compacting mold to form a group of copper conductors 1, and the array of copper conductors 1 is arranged in multiple layers to form a circle ( figure 1 ),sector( figure 2 ) and pressed together by the compression mold.

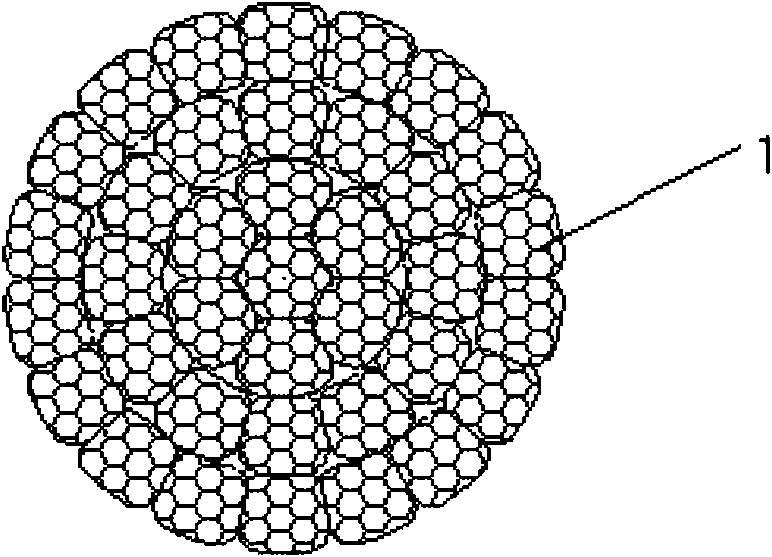

[0015] A group of copper conductors 1 is first softly stranded by several copper conductors, and the array of copper conductors 1 is arranged in multiple layers in a circle ( image 3 ),sector( Figure 4 ) and pressed together by the compression mold.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap