Method for connecting cable shielding layer with metal terminal shell

A cable shielding layer and metal terminal technology, applied in the field of digital communication, can solve the problems of soaring shielding contact resistance, inability to adjust the cable, and sharply reducing the shielding effect, so as to achieve the advantages of being conducive to signal transmission, reducing contact resistance and reducing signal leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

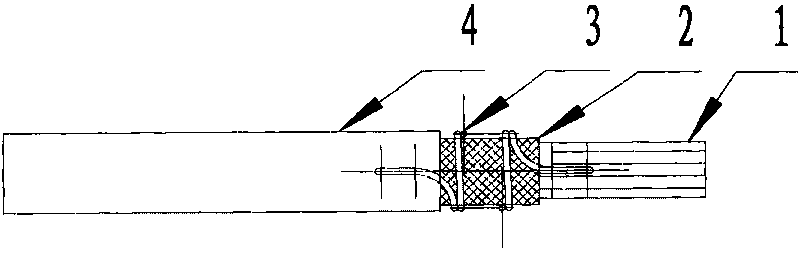

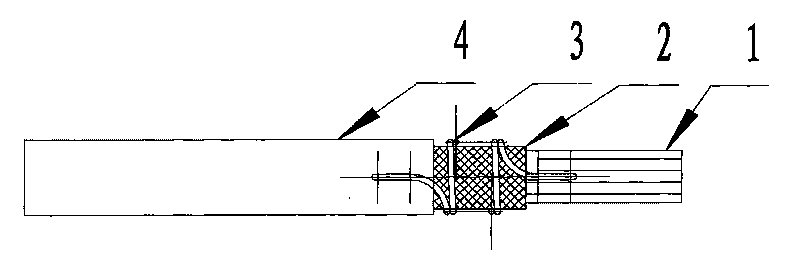

[0017] A method for connecting the cable shielding layer and the metal terminal shell, which connects the cable shielding layer and the metal terminal shell together, and is characterized in that: there is a continuous conductive shielding layer in the cable sheath, and the conductive shielding layer is wound with a copper wire twisted structure Conductors, wound conductors connected to metal terminal housings. The wound conductor is connected to the metal terminal housing by welding or crimping.

[0018] Implementation process: first peel off the cable sheath 4 to expose the braided shielding layer 2 and wire core 1 to be wound; then, wind the copper wire stranded conductor 3 on the braided layer; finally, solder or crimp the conductor to the terminal housing superior.

[0019] This embodiment improves cable and terminal contact connectivity by wrapping conductor material around the shield of the cable and then connecting the conductor to the terminal housing. Compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com