Self-adaptive triple sphere supporting device of large-scaled slide shoe tube mill

A tube mill, self-adaptive technology, applied in grain processing and other directions, can solve the problems of reasonable distribution of bearing capacity, high temperature of sliding shoes, uneven wear of sliding shoes, etc., to achieve the effect of easy guarantee of accuracy and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

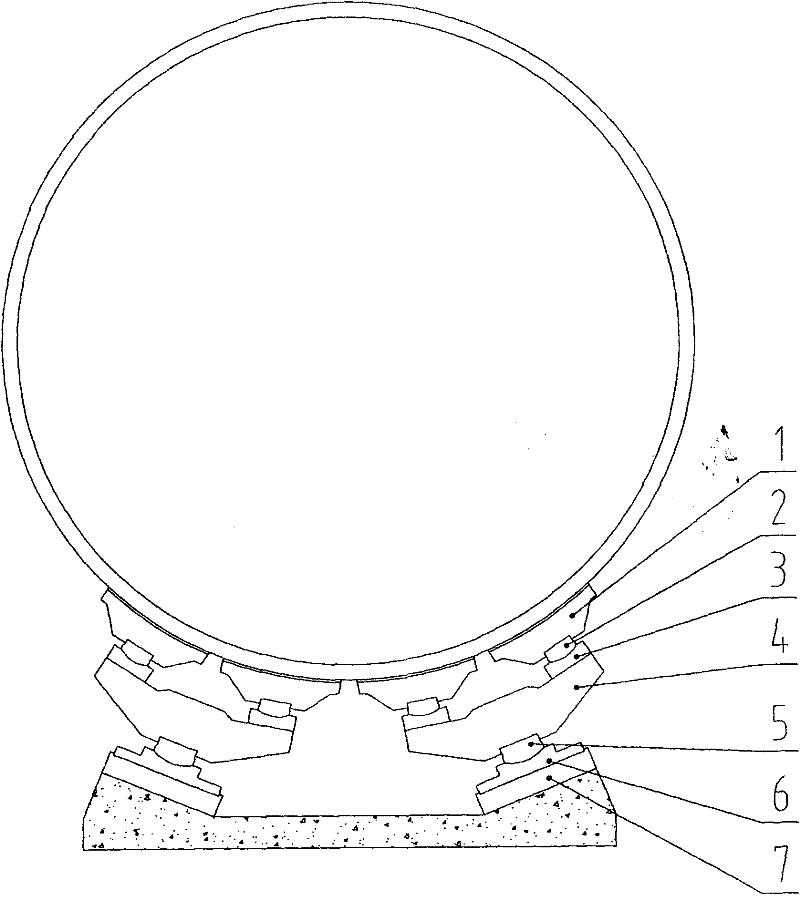

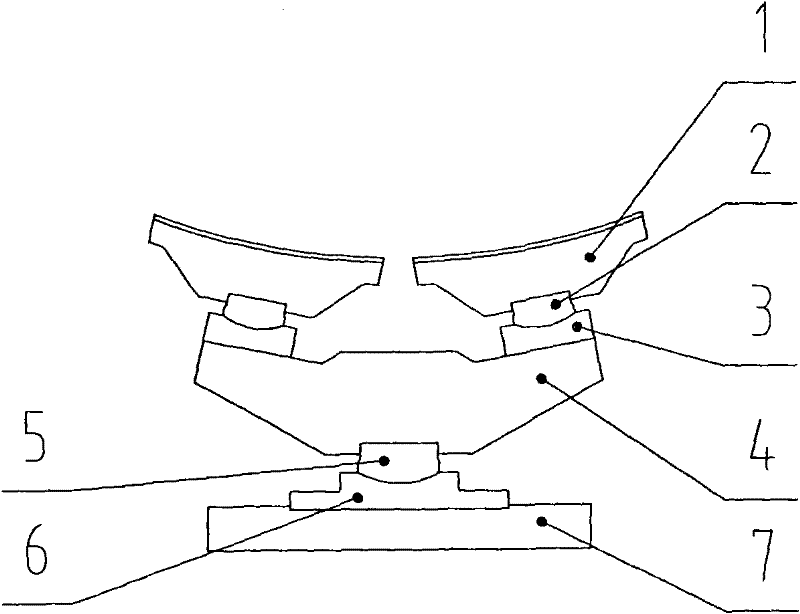

[0016] see figure 1 , the structure of the self-adaptive three-sphere support device of the large sliding shoe tube mill described in the present invention is as follows:

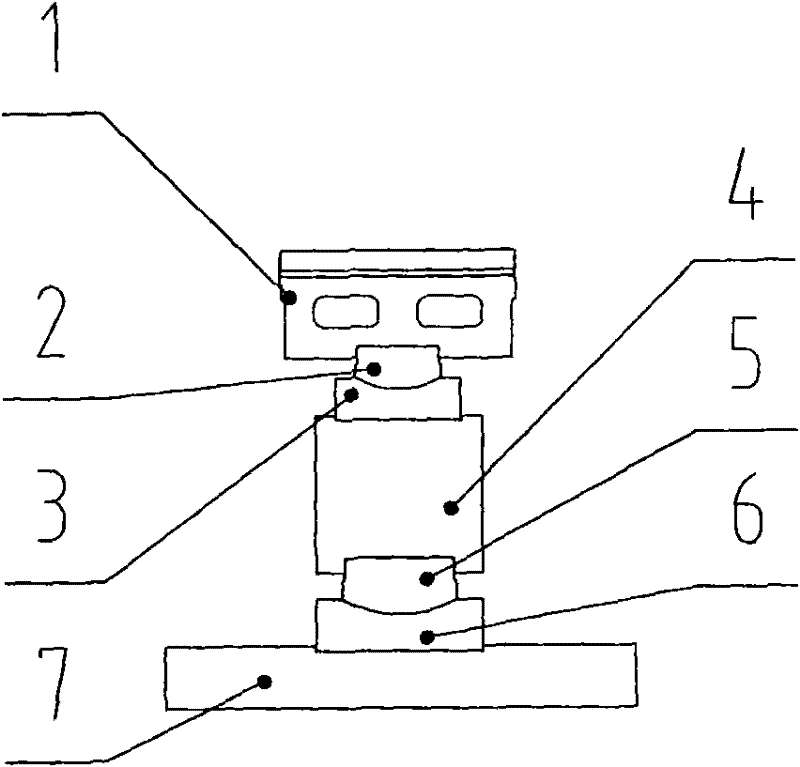

[0017] The convex spherical tile seat 2 is installed in the bottom groove of the sliding shoe shoe body 1, the lower part of the convex spherical tile seat 2 is concavo-convexly matched with the upper part of the concave spherical tile seat 3, and the sliding shoe tile body 1 is connected with the convex spherical tile seat 2 and the concave spherical tile seat. 3 are combined into a shoe shoe unit, and the deflection requirements of the shoe shoe in all directions are realized through spherical cooperation.

[0018] The two above-mentioned shoe shoe units are fixed on the supporting seat body 4 by bolts, the bottom of the supporting seat body 4 is installed on the convex ball sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com