Gravity flow quantitative pouring continuous casting continuous forging equipment

A technology of continuous casting, continuous forging and quantitative pouring, which is used in foundry equipment, equipment for feeding molten metal into casting molds, and metal processing equipment, which can solve problems such as energy consumption and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

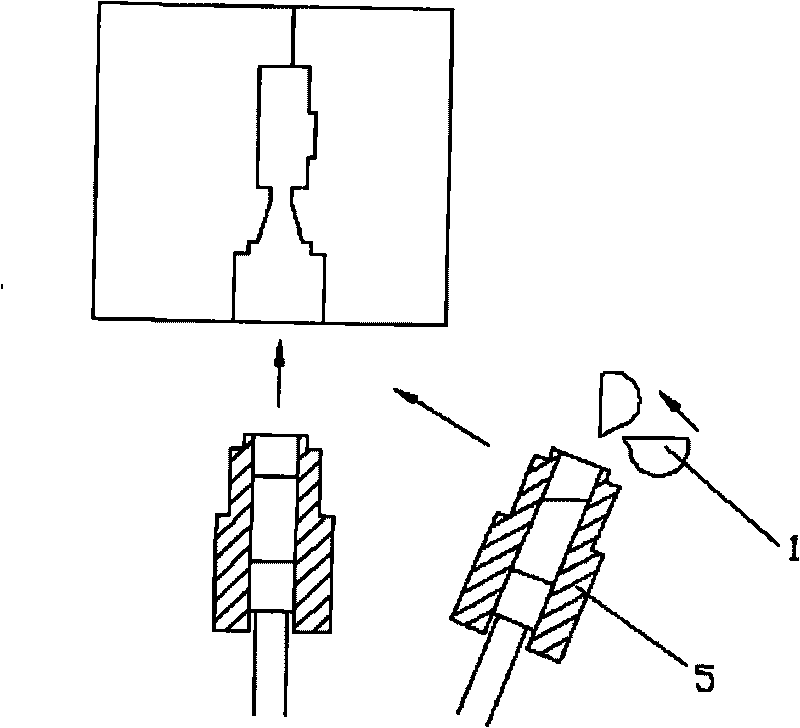

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

[0027] First, the mold is placed on the mold placement platform 5, and the mold clamping hydraulic cylinder 1 is activated so that the pressure head of the mold clamping hydraulic cylinder closely contacts the upper template of the mold; The controllable displacement of the upper mold cavity insert 14 is connected;

[0028] Second, open the rotary spool 9 installed on the liquid metal flow channel 8 and the rotary valve body 10, so that the liquid metal will flow quantitatively into the liquid storage cylinder through the liquid metal flow channel 8 and the rotary spool 9 on the rotary valve body 10 11, close the rotary spool 9;

[0029] Its three, start the injection hydraulic cylinder 6 to make the pressure head 12 of the liquid storage cylinder move up at a predetermined speed, and the liquid or semi-solid metal hydraulic pressure in the liquid storage cylinder 11 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com