Pouring-type casting platform of continuous casting machine

A continuous casting machine and platform technology, which is applied to casting equipment, casting melt containers, metal processing equipment, etc., can solve problems such as scalding workers, screw screw jamming, and molten metal overflow, and achieve the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

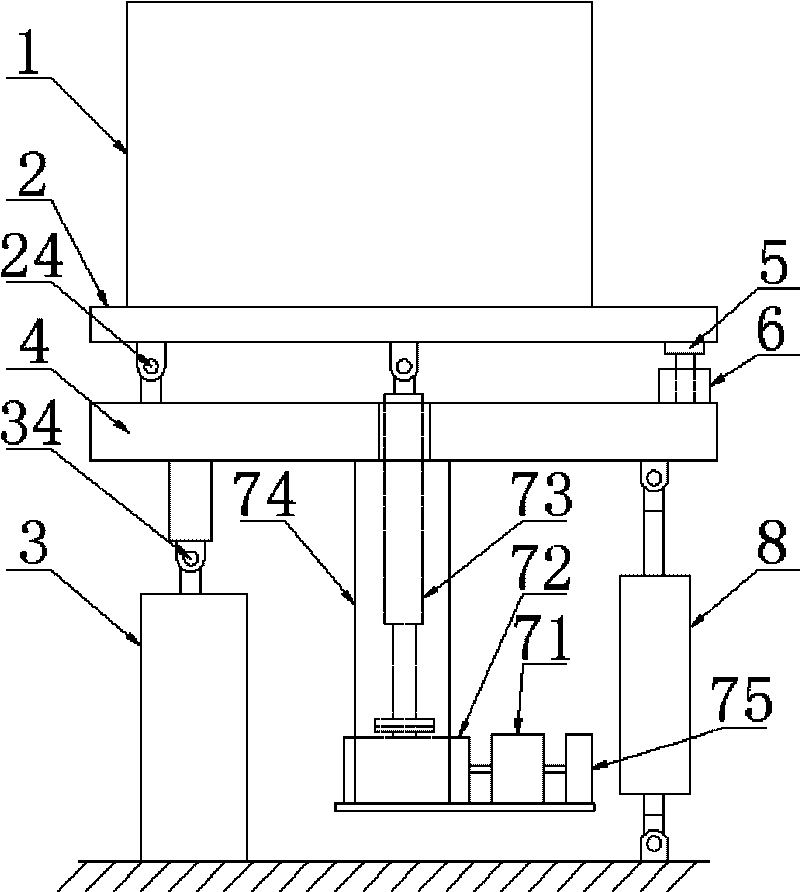

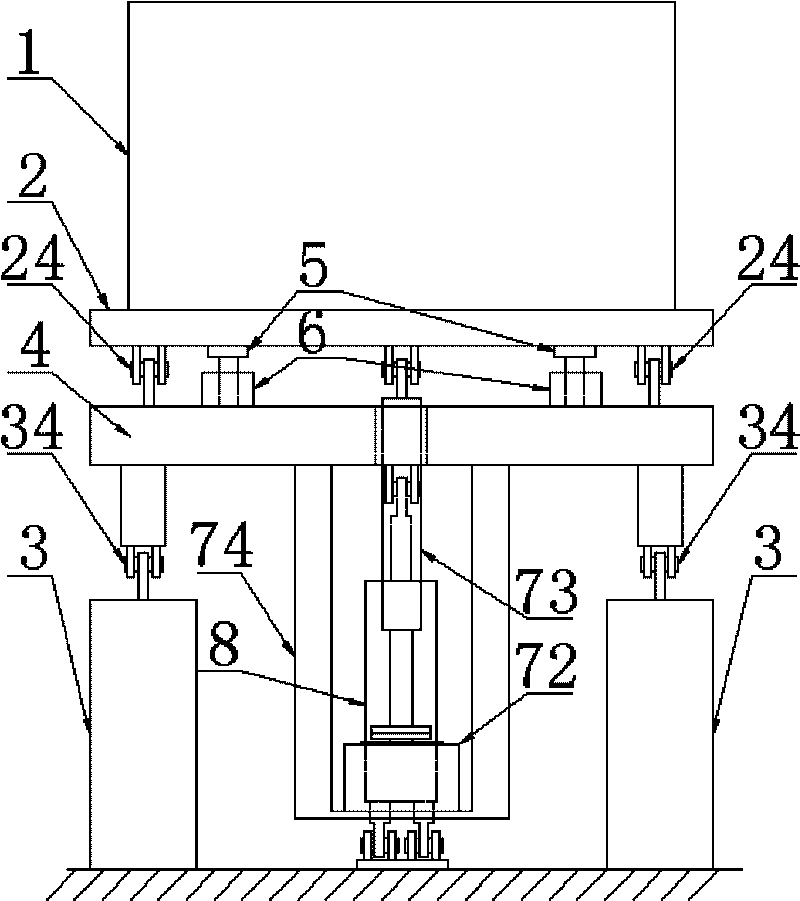

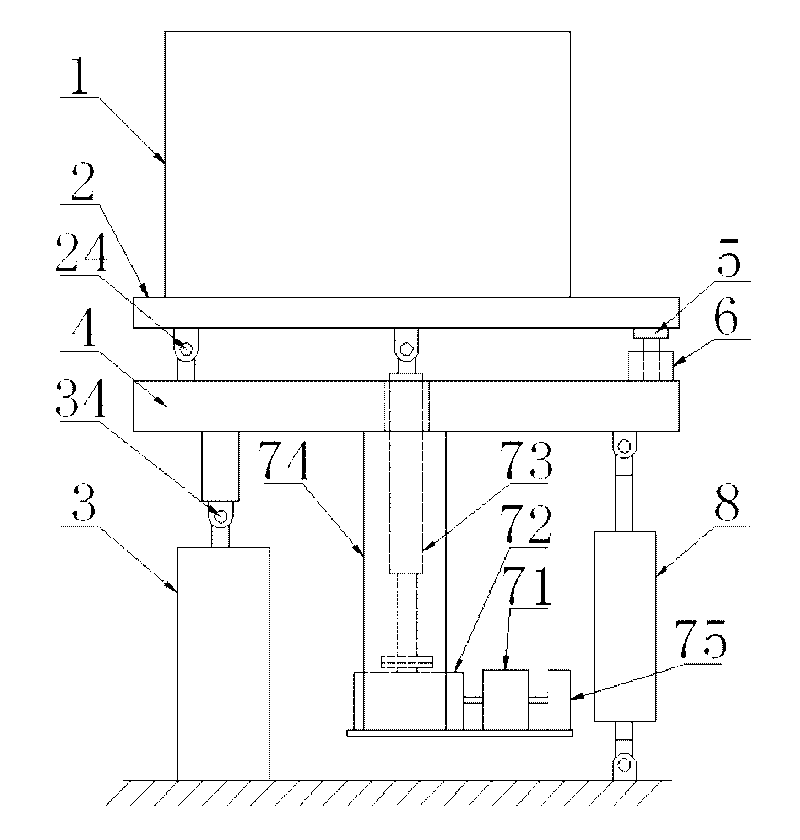

[0010] Such as figure 1 , figure 2 As shown, the pouring casting platform of the continuous casting machine of the present invention includes a tundish 1 and its supporting platform 2, one end of the supporting platform 2 is hinged and rotates around its hinge point 24 with the linear drive mechanism, and one end is hinged on the bracket 3 The intermediate platform 4 rotates around its hinge point 34 with the emergency linear drive mechanism; the support platform 2 is hinged on the intermediate platform 4, and the linear drive mechanism is fixed on the intermediate platform 4.

[0011] During casting, the tundish 1 rotates forwardly around the hinge point 24 with its support platform 2 driven by the linear drive mechanism, the tundish 1 is lifted up, and the molten metal in the tundish 1 is poured into the ladle of the continuous casting machine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com