An ejection device that enables steady and sustained acceleration of objects

An ejection device and a stable technology, which is applied in the direction of launch/drag transmission, etc., can solve the problems that the aircraft cannot reach the take-off speed, burn out the coil electronic devices, and the acceleration becomes low in the later stage, so as to achieve uniform ejection speed and low maintenance cost , The effect of long boost distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

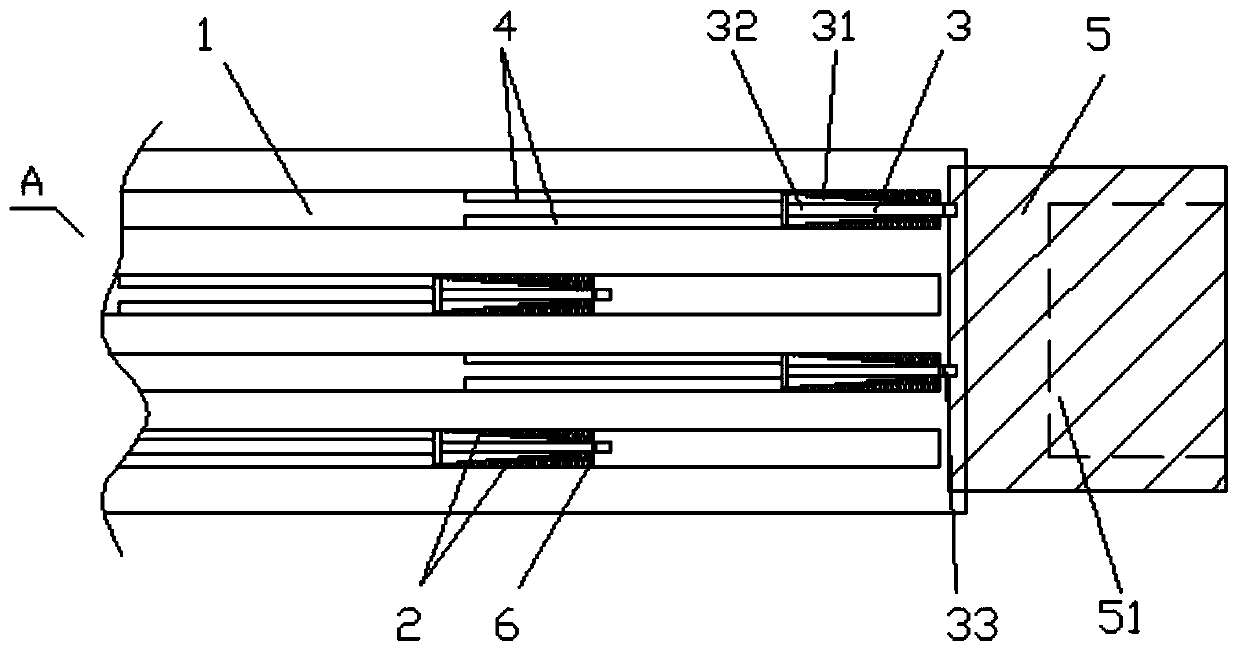

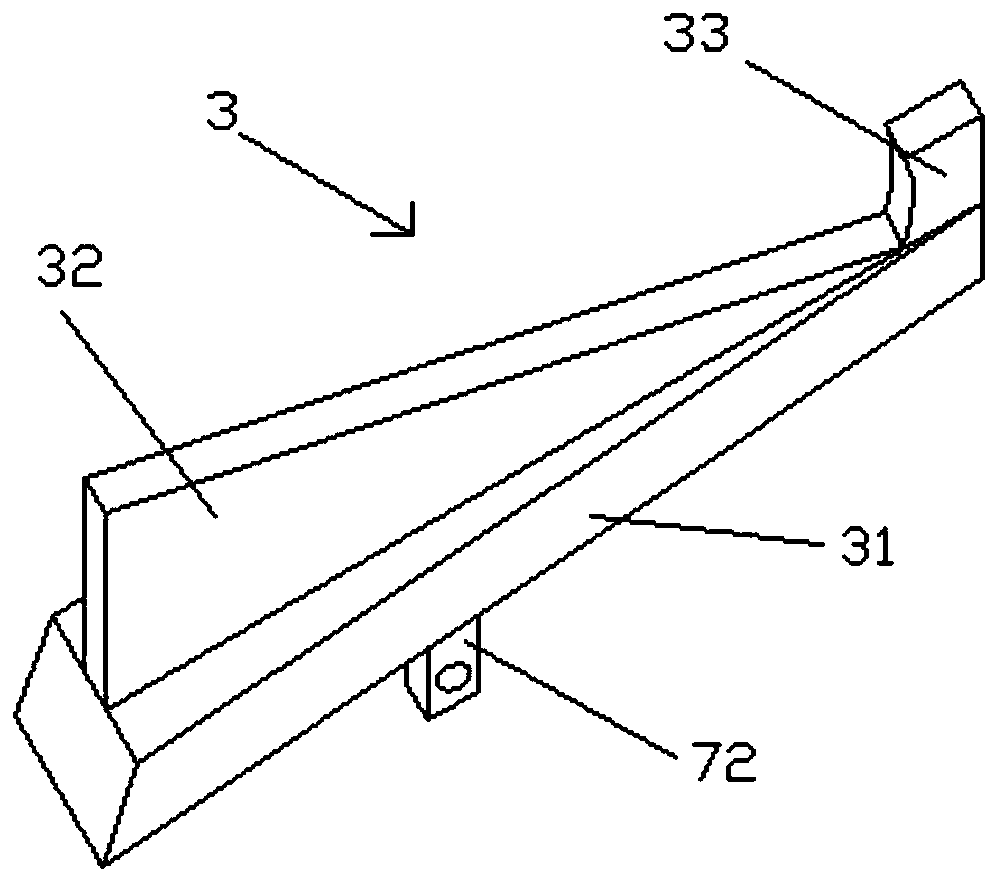

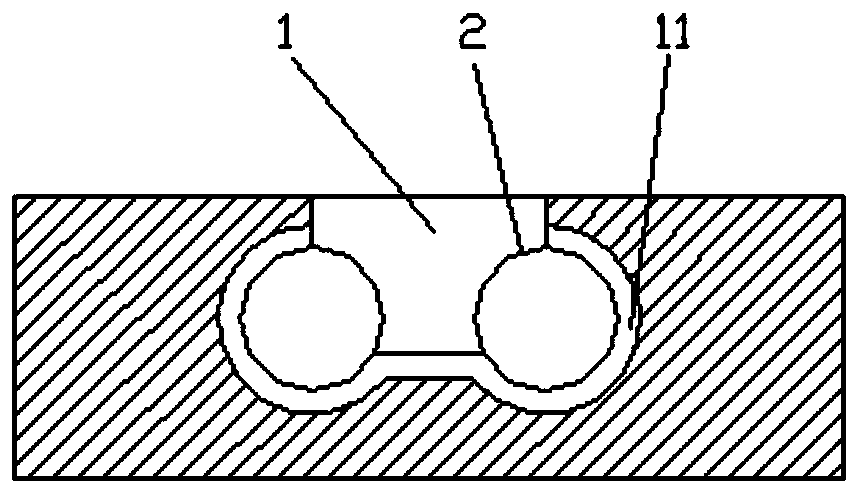

[0030] The purpose of this embodiment is to provide an ejection structure capable of stably accelerating an object, such as figure 1 As shown, the ejection structure in this embodiment is mainly used for the purpose of multi-stage ejection and continuous boosting of the aircraft. Specifically, the ejection structure includes a plurality of ejection paths 1 parallel to each other. There is an ejection structure, and the ejection structures in the adjacent ejection paths are misplaced; the installation positions of the ejection structures in the two ejection paths of the alternate ejection path 1 are the same and are triggered synchronously, so as to achieve the purpose of uniform ejection speed, so that the aircraft is evenly stressed and accelerates smoothly , to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com