Impeller for spray processing device, manufacturing method of impeller, and spray processing device

A processing device and impeller technology, applied in the direction of manufacturing tools, additive manufacturing, impellers, etc., can solve the problems of air compression and air flow rate without considering the flow path of abrasive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Next, embodiments of the present invention will be described with reference to the drawings.

[0087] (Overall structure of blasting machine)

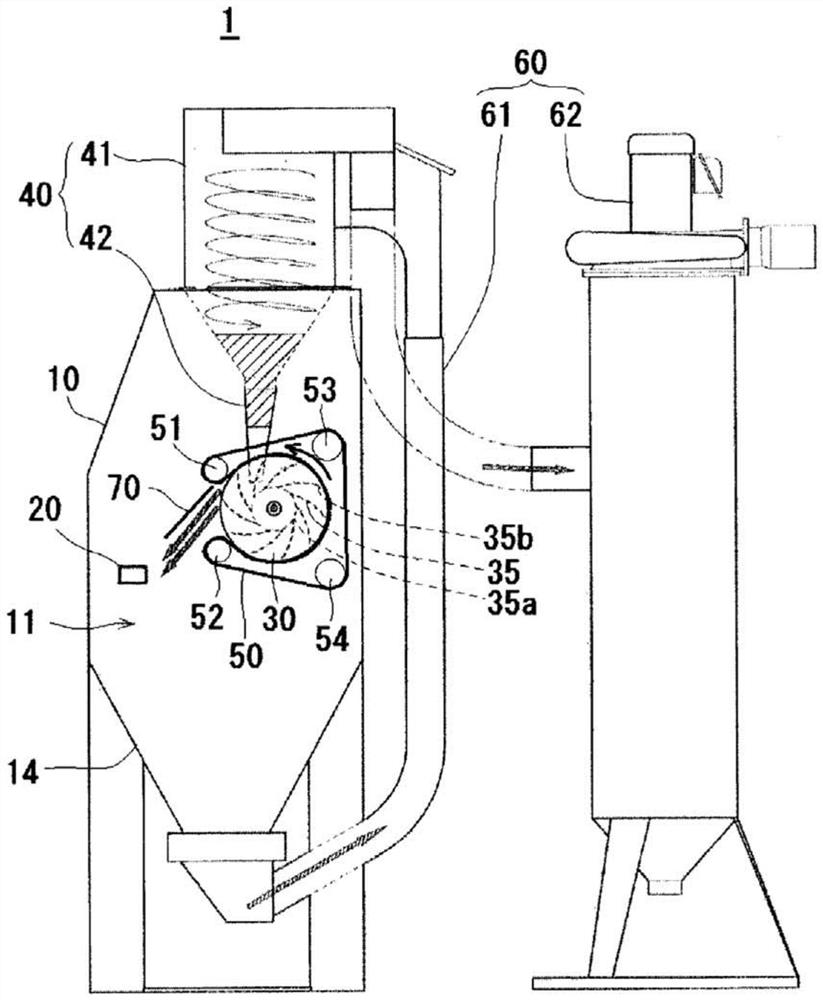

[0088] figure 1 The whole structure of the blast processing apparatus 1 of this invention is shown.

[0089] The blast machining apparatus 1 is configured to project the abrasive material to the workpiece 20 in the machining chamber 11 formed in the housing 10 so as to prevent the scattering of abrasive material and cutting powder, etc., and cause pollution of the working environment. The object 20 is provided on the side wall of the casing 10 in a state capable of opening and closing with respect to an entrance (not shown) for entering and exiting the processing chamber 11 .

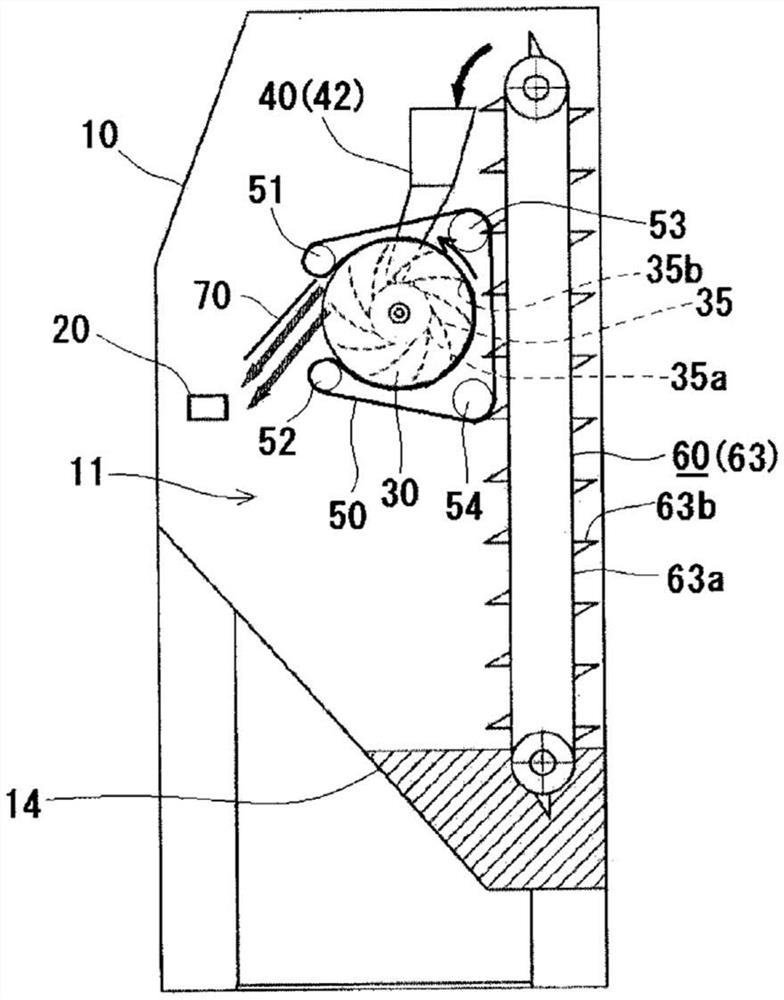

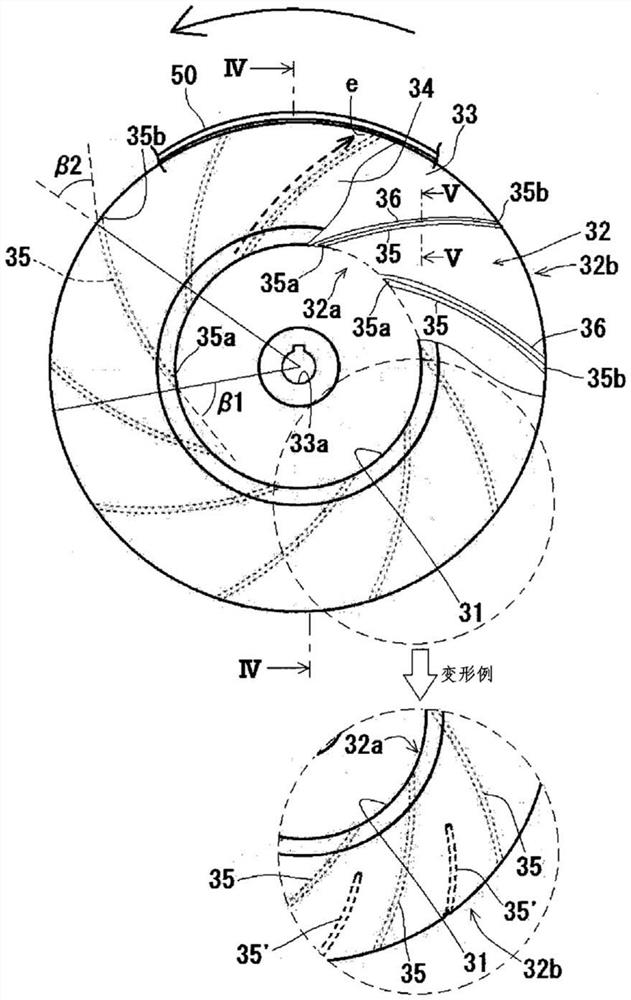

[0090] The machining chamber 11 includes an impeller 30 as an abrasive acceleration mechanism, an abrasive supply mechanism 40 for supplying abrasive to the impeller, and a covering mechanism 50 for covering the outer periphery of the impeller 30 excep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com