Alumina conveying system and method

A conveying system, alumina technology, applied in the direction of alumina/aluminum hydroxide, conveyor objects, transportation and packaging, etc., can solve the problem of fast wear of the conveying system, high energy consumption of the pneumatic lifting device, increase of intermediate links and energy consumption, etc. problems, to achieve the effect of reducing transmission links, reducing power consumption, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Test run the method of the present invention in certain alumina factory.

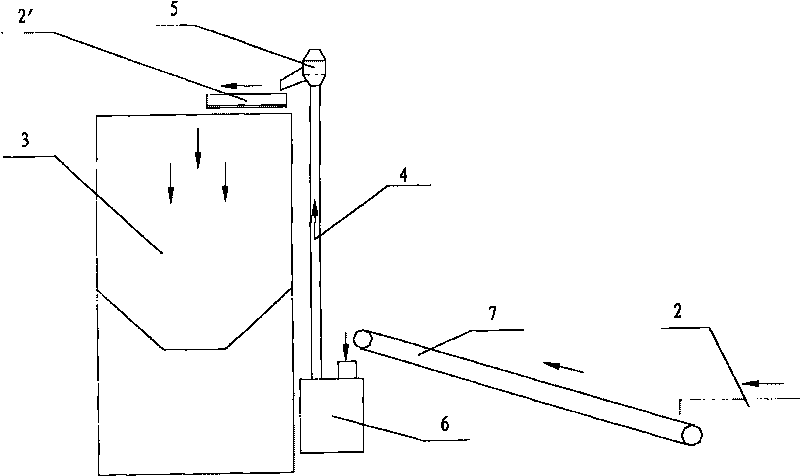

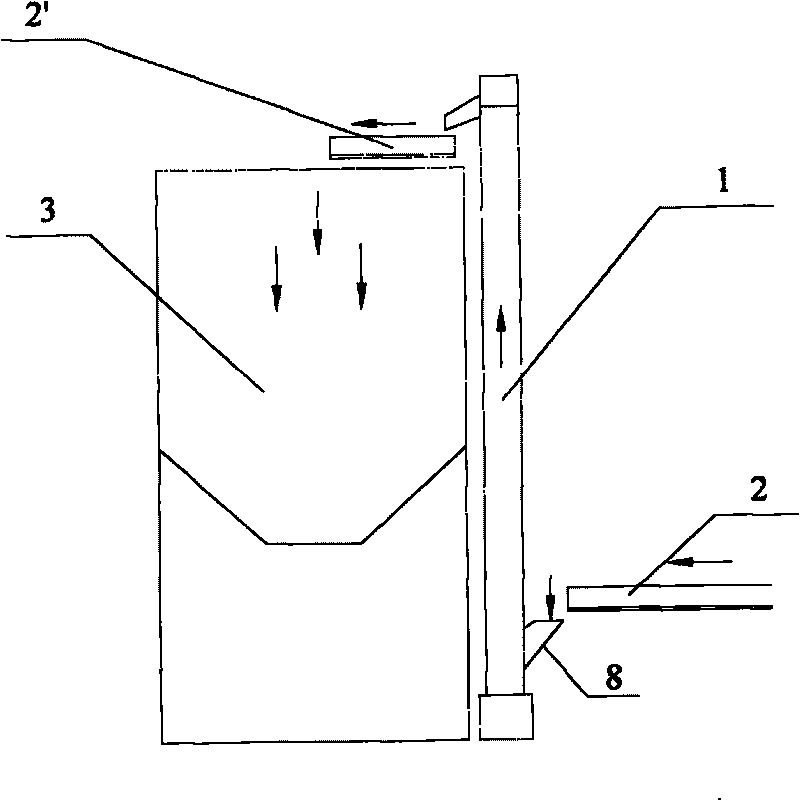

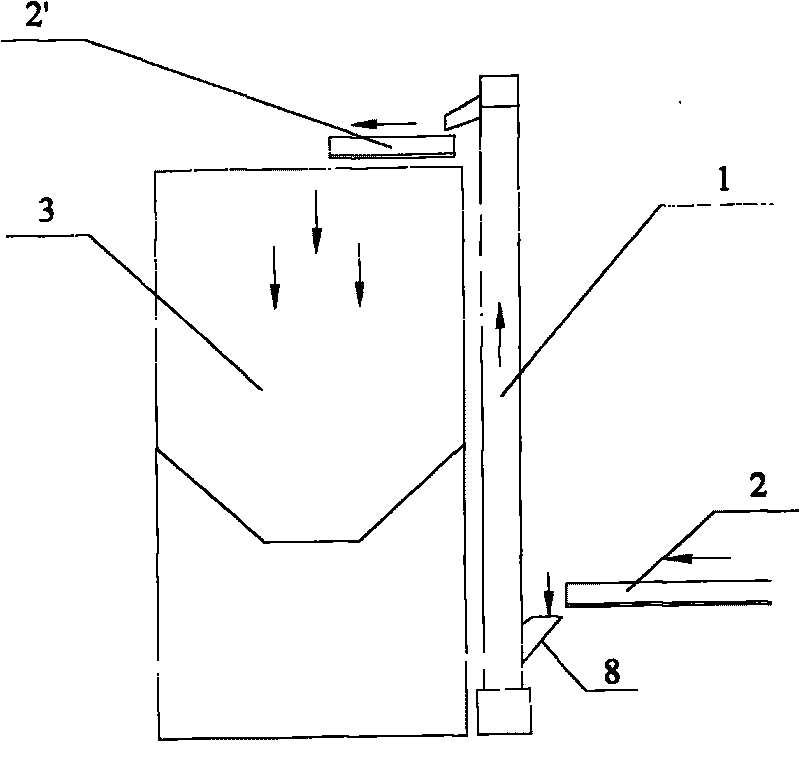

[0023] Configure a B800×46450mm steel wire belt bucket elevator (N-TGD type, Hefei Cement Research and Design Institute), configure a motor Y280S-4 / 75kw, design a conveying capacity of 500t / h, and a lifting height of 45 meters, close to alumina The silo is set up and equipped with 2 pneumatic chutes. Constitutes the delivery system for alumina.

[0024] Such as figure 2 As shown, the alumina conveying system includes chute I 2, bucket elevator 1 and chute II 2', chute I 2 is used to convey alumina to the drop hopper 8 of bucket elevator 1, which is next to the alumina The silo 3 is set to lift the alumina to the top of the alumina silo 3; the chute II 2' is set on the top of the alumina silo 3, and is used to send the alumina lifted to the top of the alumina silo 3 Alumina silo 3.

[0025] The finished alumina product is directly transported to the hopper 8 of the steel belt type bucket elev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com