Coupler

A coupling and half-coupling technology, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc. Due to the problems of compactness and low coupling strength, it achieves the effect of high manufacturing precision, simple structure and compact combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved objects and effects of the present invention in detail, the following detailed description is given in conjunction with the embodiments and the accompanying drawings.

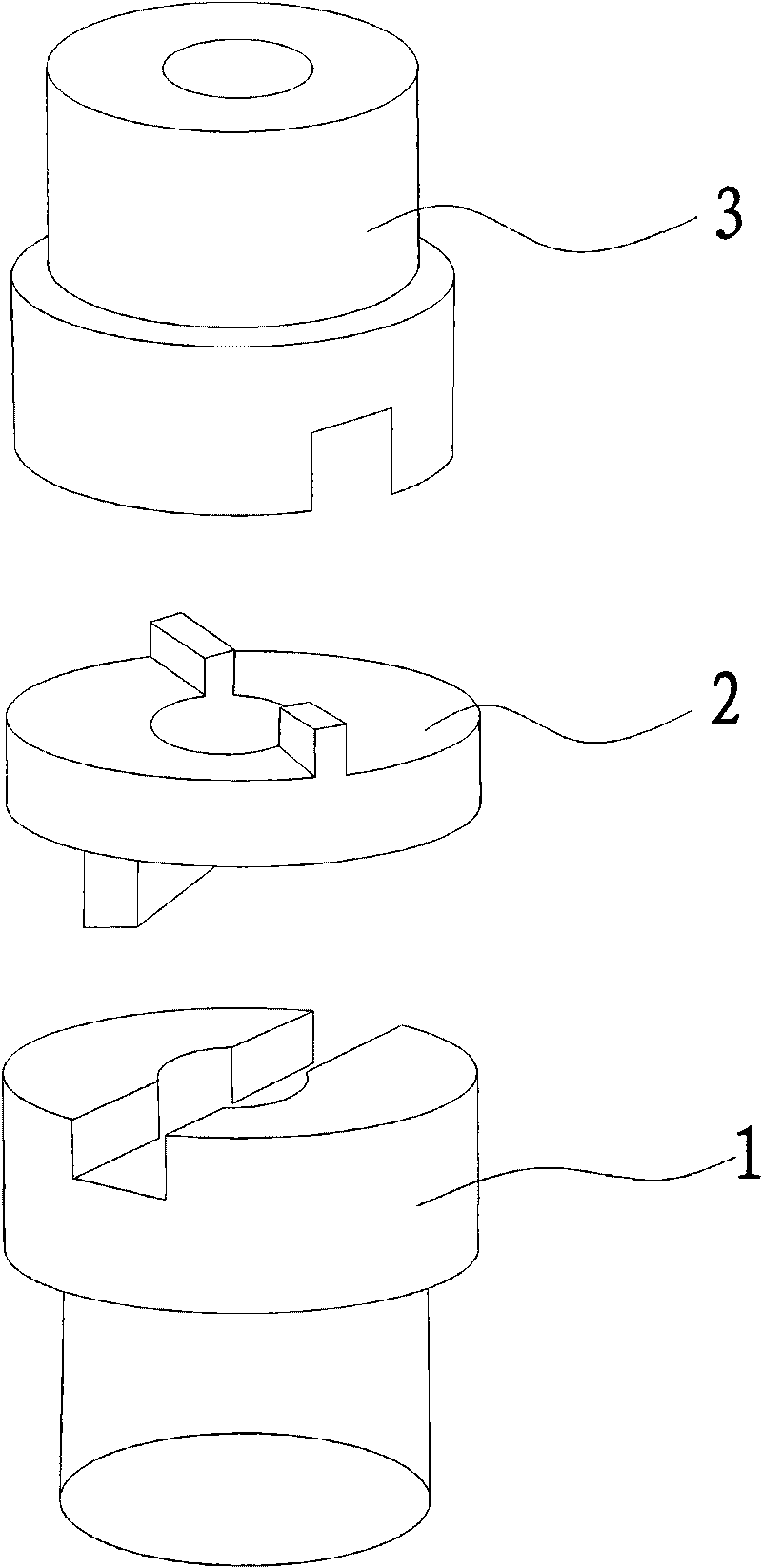

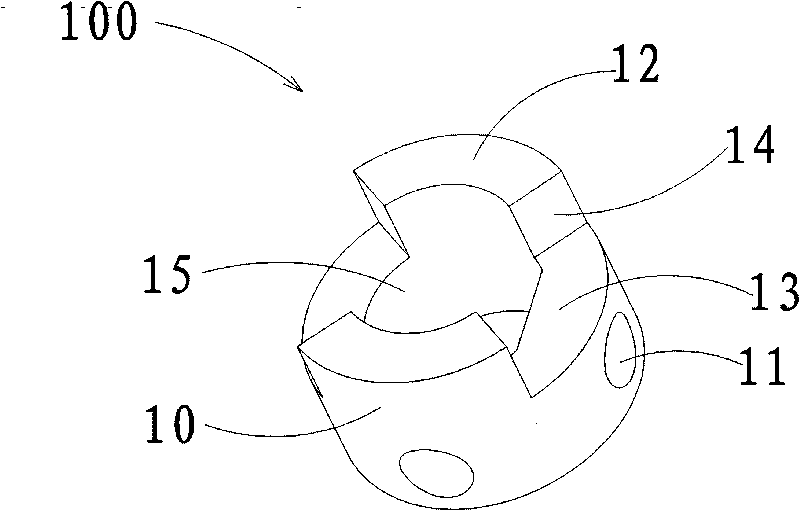

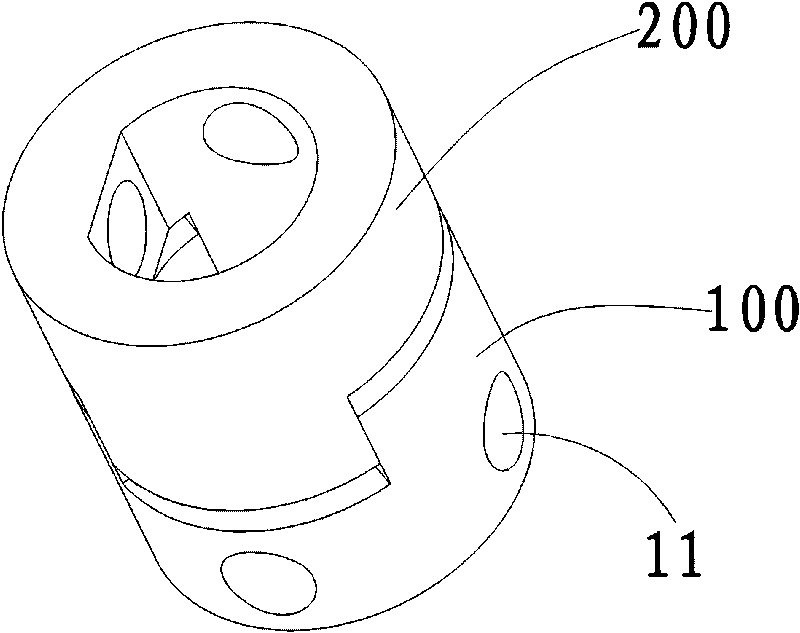

[0022] see figure 2 and image 3 , which is an embodiment of the coupling of the present invention, including a first half coupling 100 and a second half coupling 200, the first half coupling 100 and the second half coupling 200 have complete the same structure. The first half coupling 100 has a cylindrical coupling body 10, the coupling body 10 has a positioning hole 15 penetrating the upper and lower end surfaces of the coupling body 10, the positioning hole 15 is formed by A closed figure formed by a chord and a straight line or a closed figure formed by arcs with different radii. In this embodiment, the positioning hole 15 is in the shape of a moon or a polygon. The side edge of the coupling body 10 is provided with a slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com