Male joint of coaxial cable connector

A coaxial cable and connector technology, applied in the direction of conductive connection, connection, two-component connection device, etc., can solve the problems of instability, difficult operation, poor intermodulation performance, etc., and achieve the effect of good versatility and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

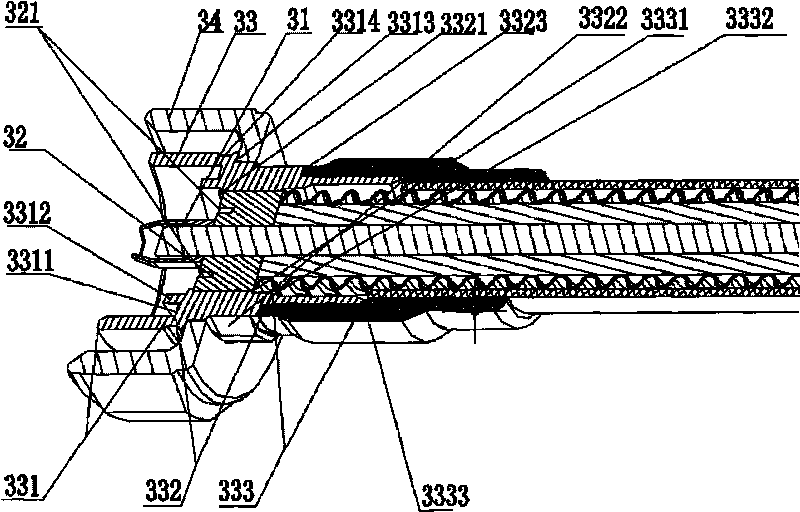

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] The following embodiment introduces a male-female mating interface that is applied to a male connector of a 7 / 16-type coaxial cable connector and meets the DIN 47223 standard widely released around the world. However, the basic structural improvements proposed in this embodiment can be widely used in various standard coaxial cable connectors. For the convenience of description, the direction of the plugging interface between the male connector and the female connector is referred to as the front end, and the end where the coaxial cable is terminated is referred to as the rear end.

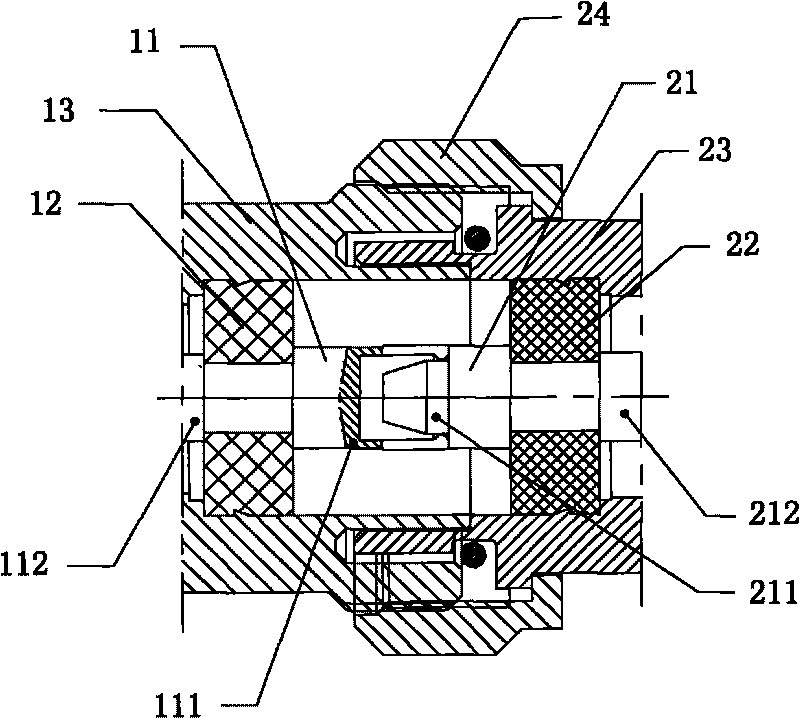

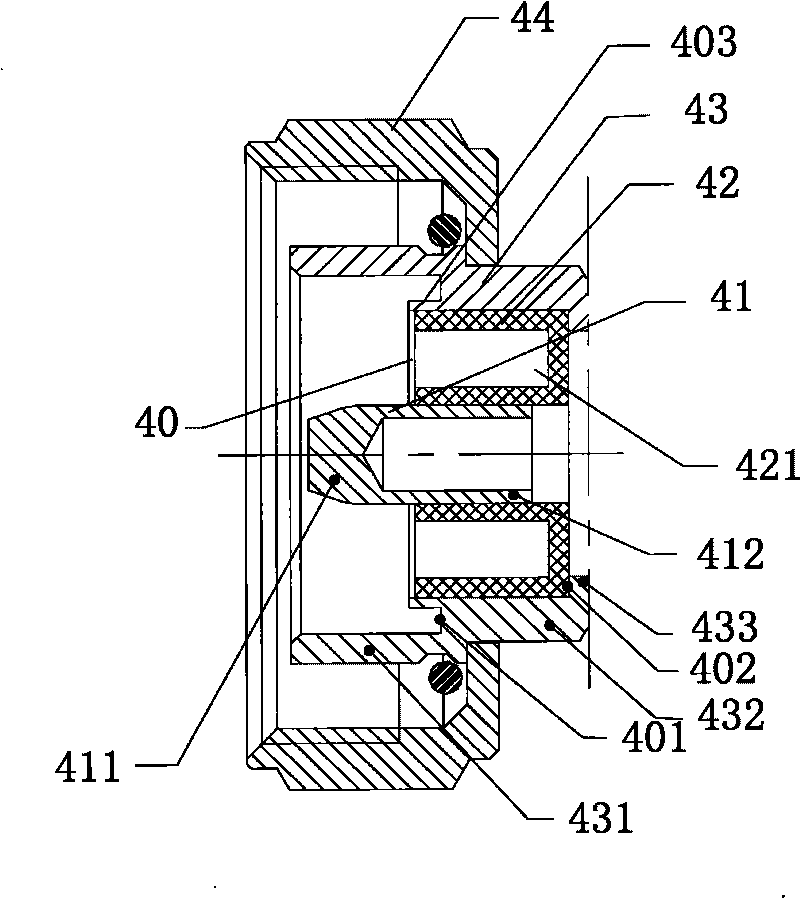

[0038] like image 3 As shown, the male joint of the coaxial cable connector according to Embodiment 1 of the present invention has a ring-shaped structure with inner, middle and outer layers. The front end portion of the central conductor 41 has a tapered protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com