Rotor sectional type flux switching motor and method for improving sine degree of back electromotive force thereof

A magnetic flux switching motor, segmented technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of large back EMF amplitude of back EMF harmonics, incomplete symmetry of the body structure of the magnetic flux switching motor, etc. Achieve the effect of high back EMF amplitude, high power density and high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

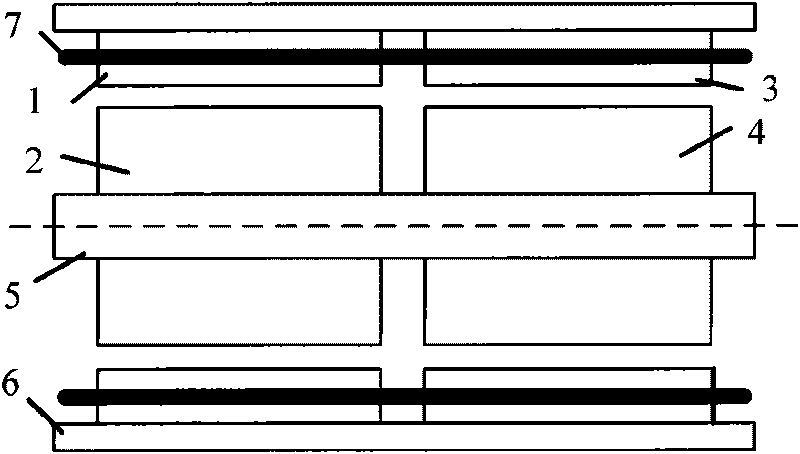

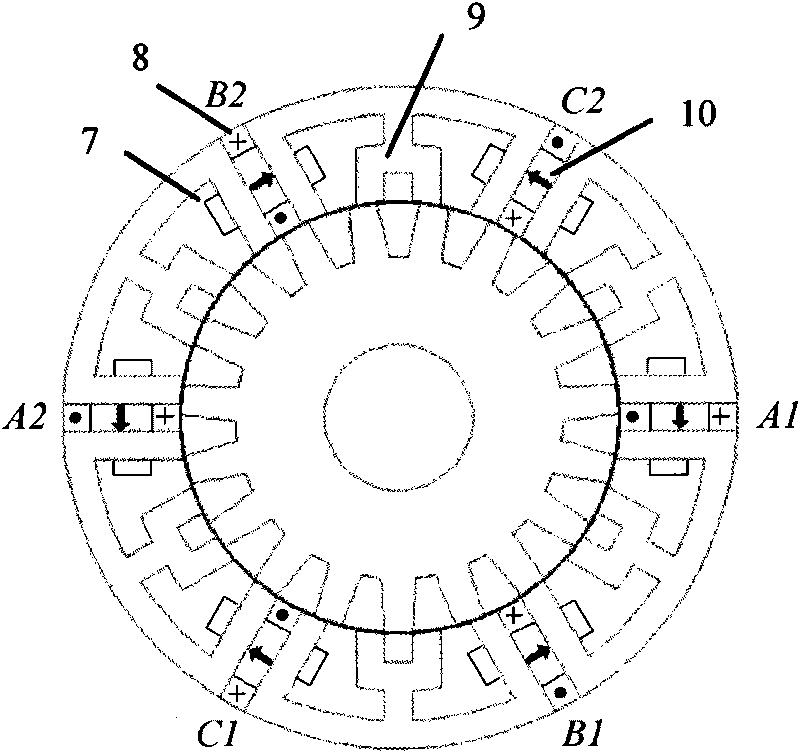

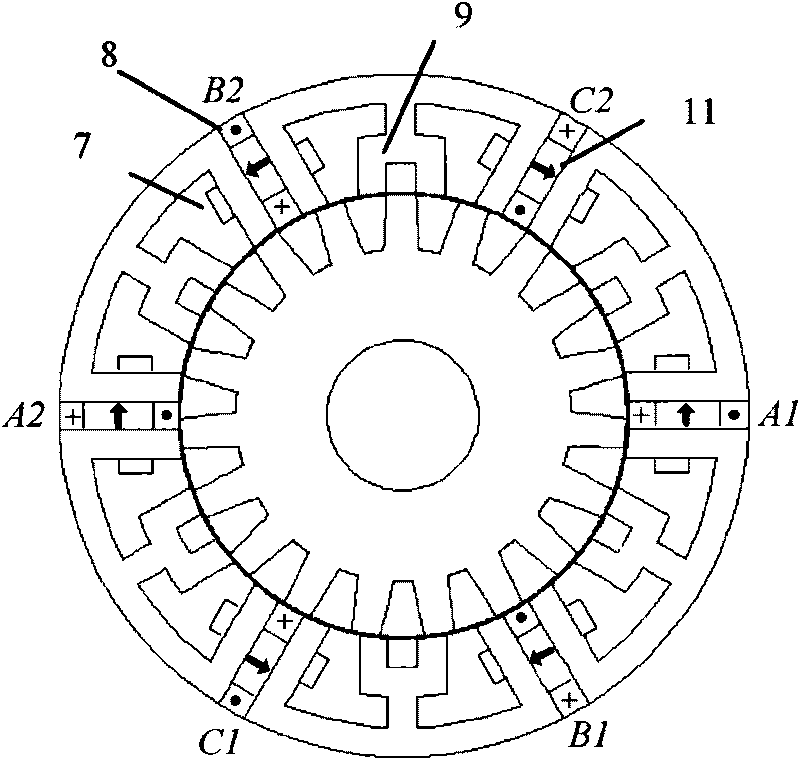

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a rotor segmented flux switching motor includes a salient pole stator A, a salient pole stator B, a salient pole rotor A, a salient pole rotor B, the salient pole rotor A and the salient pole rotor B are connected with the rotating shaft, and the salient pole Stator A and salient pole stator B share a set of armature windings. The cross-sectional geometry and axial length of the two stators are completely consistent, and the space angles of the two stators are consistent. The difference is that the excitation directions of the permanent magnets facing each other in the two stators are opposite. The cross-sectional geometric shape and axial length of the two parts of the rotor are exactly the same, and the space angle difference between the two parts of the rotor is α, and α must satisfy the formula (1)

[0025]

[0026] Formula (1), P r is the number of rotor teeth.

[0027] Figure 5 It is the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com