Reversely deformed jig frame for welding U ribs of steel box girder

An anti-deformation, steel box girder technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the U-rib and the panel cannot be reliably welded, the manufacturing accuracy of the panel unit is affected, and the panel welding angle is deformed, etc. problems, to achieve the effect of reducing manual correction man-hours, simple structure, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

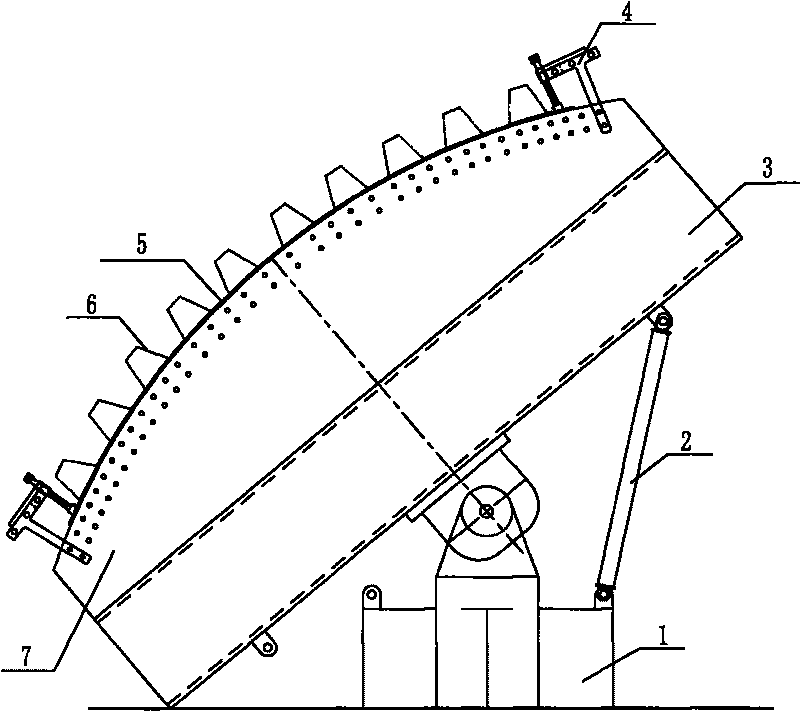

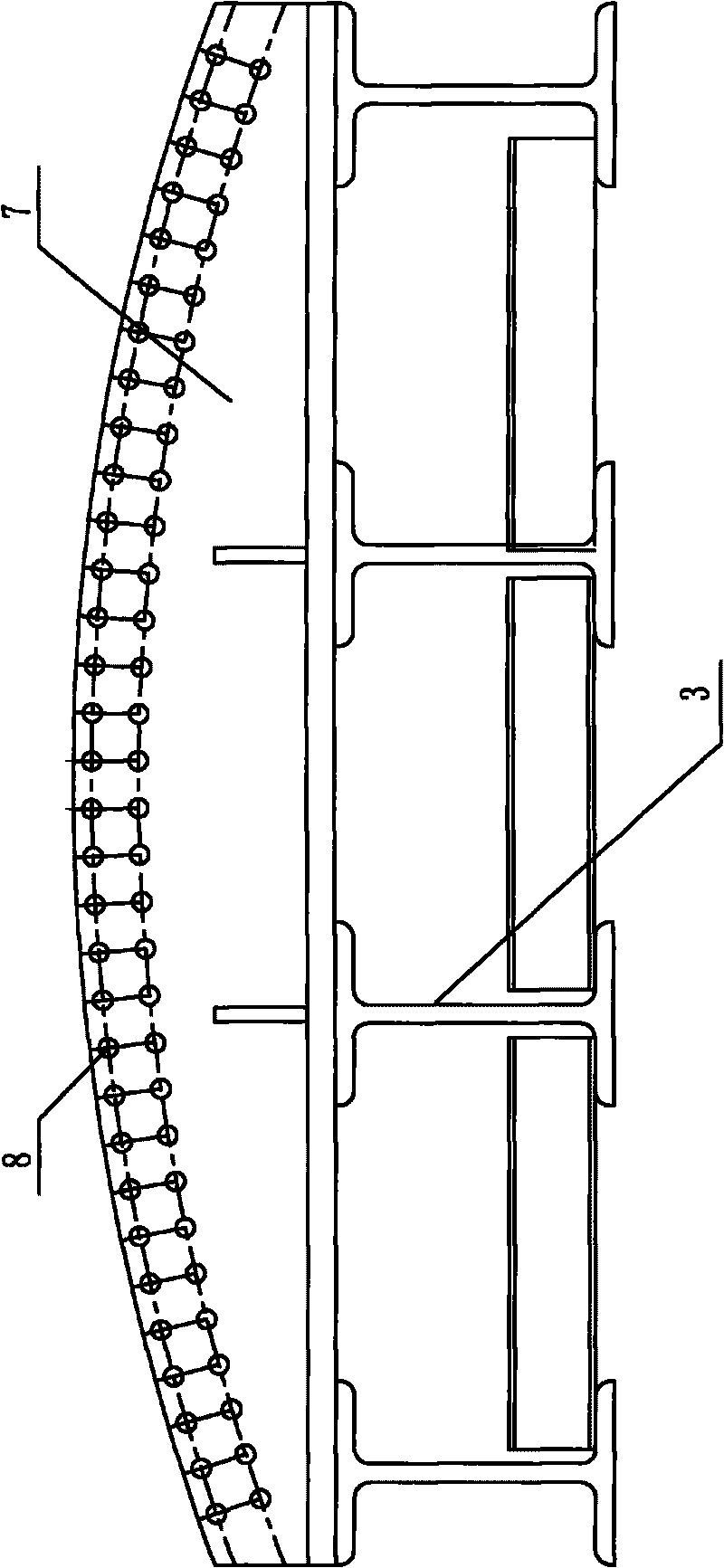

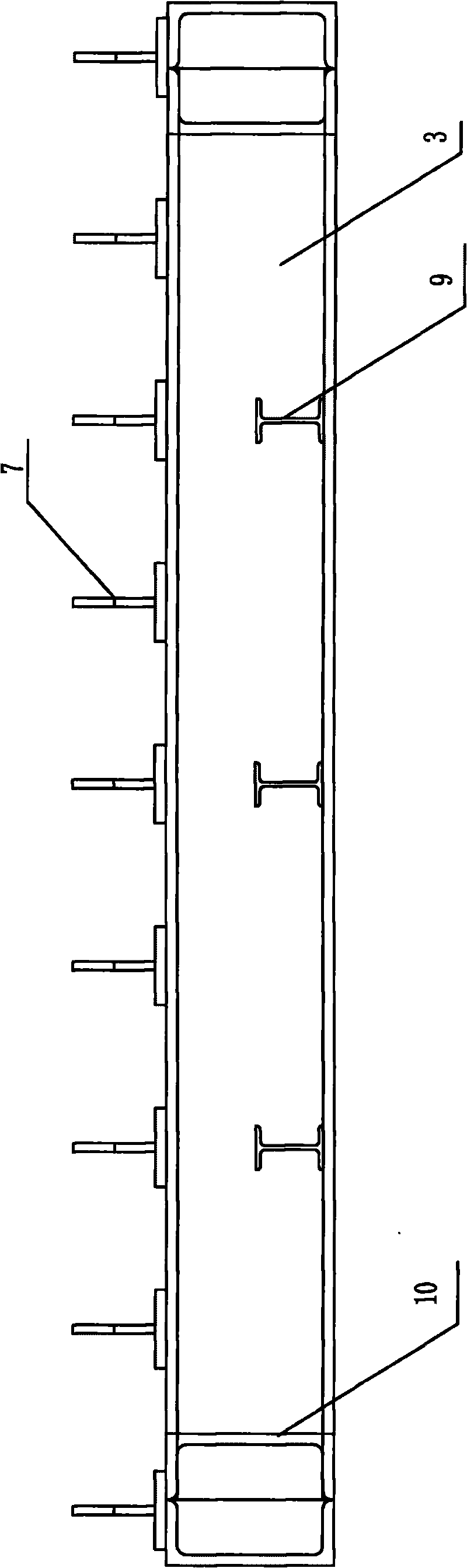

[0014] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the embodiments and accompanying drawings, see Figure 1 to Figure 4 :

[0015] According to the present invention, an anti-deformation frame for steel box girder U-rib welding includes a base 1, a frame 3, a strut 2, an arc plate 7, and a fixture 4, and the base 1 is welded by I-shaped steel And fixed on the ground foundation, the frame 3 is welded by the I-beam 9 and the channel steel 10 to form a frame structure, the base 1 is hinged with the bottom of the frame 3 through the pin shaft, and the upper surface of the frame 3 is welded with an arc plate 7, an arc plate 7 Welding at equal intervals parallel to the width direction of the frame 3, the arc plate 7 is arc-shaped to give a pre-deformation to the panel 5 to offset the angular deformation generated during welding, and the mid-span sagittal height of the arc pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com