Driving mechanism of track-type transporting vehicle

A technology of driving mechanism and transport vehicle, which is applied in the direction of wheel axle self-adjustment, etc., can solve the problems that it is difficult to meet high-speed driving and large-volume handling, unfavorable rail system expansion and change, and the economic efficiency of use is not optimized, so as to facilitate the change and expansion, reducing the probability of failure, the effect of concise and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be further described below in conjunction with the accompanying drawings, but not limited to the embodiments.

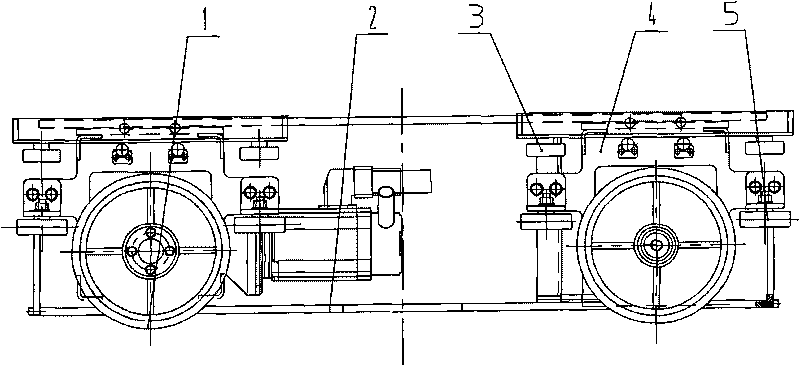

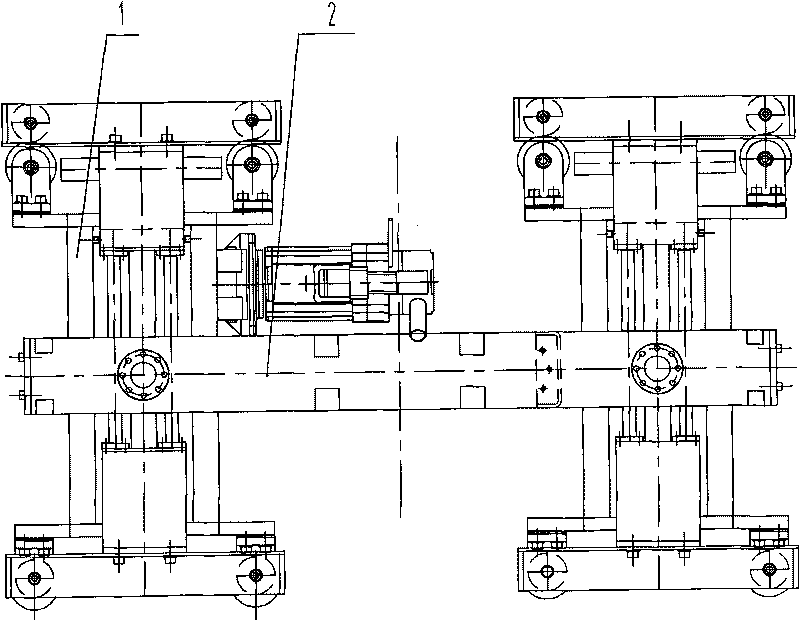

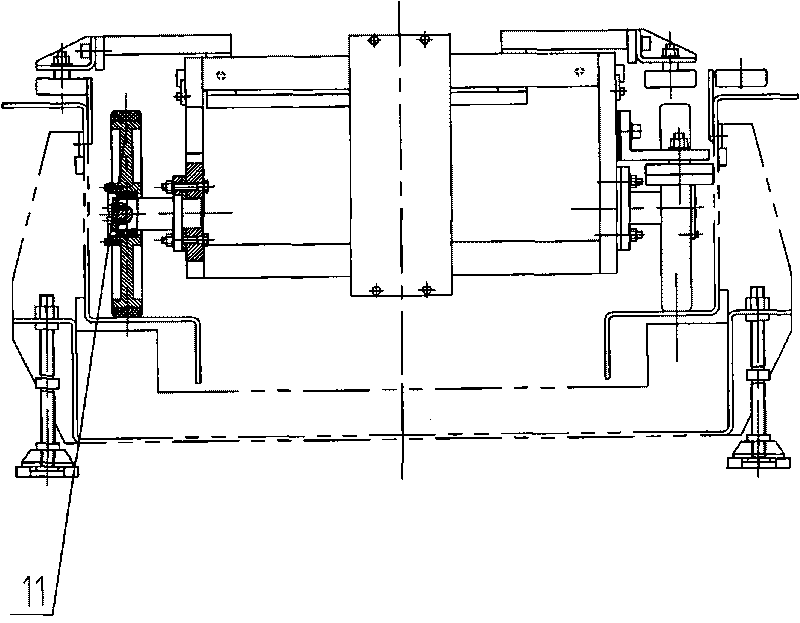

[0019] Such as figure 1 As shown, the present invention is made up of three major parts such as driving unit 1, follow-up unit 4 and supporting frame unit 2. Wherein the support frame 2 is equipped with a slewing bearing 9 which is matched and connected with the slewing shafts in the driving unit 1 and the follower unit 4 . The drive unit 1 and the follow-up unit 4 are equipped with a track selection device 7 with four rollers 3, and the side faces of the drive unit and the follow-up unit are respectively equipped with a total of 8 guide wheels 5. Wherein the drive unit is also equipped with a single power drive unit 8 with a differential speed, and the single power drive unit 8 is equipped with a differential speed device 10, a power motor 8 and a driving wheel 6. The follower unit 4 is equipped with two follower wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com