Method for manufacturing red glutinous rice wine

A manufacturing method and technology of blood glutinous rice, which are applied in the field of rice wine manufacturing, can solve problems such as not meeting the requirements of green food, and achieve the effects of transparent color, sweet aftertaste, bright and natural color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

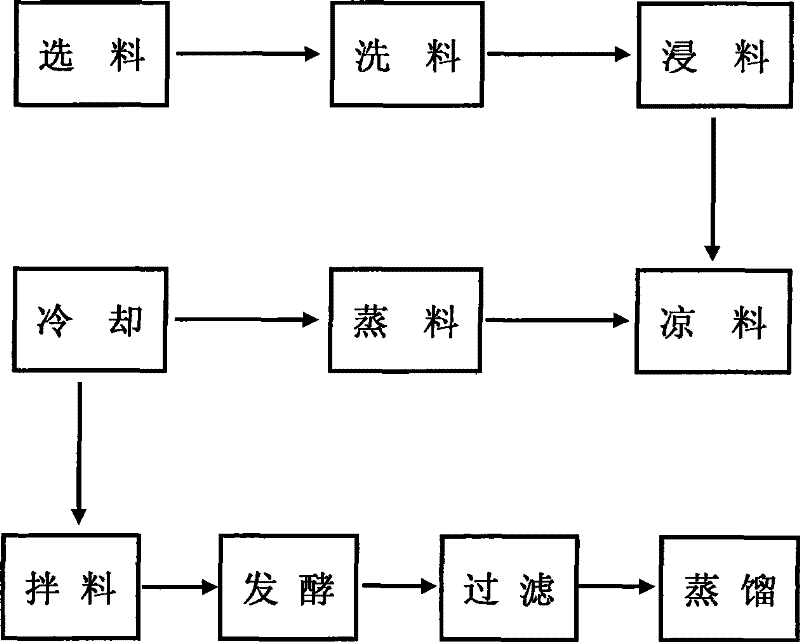

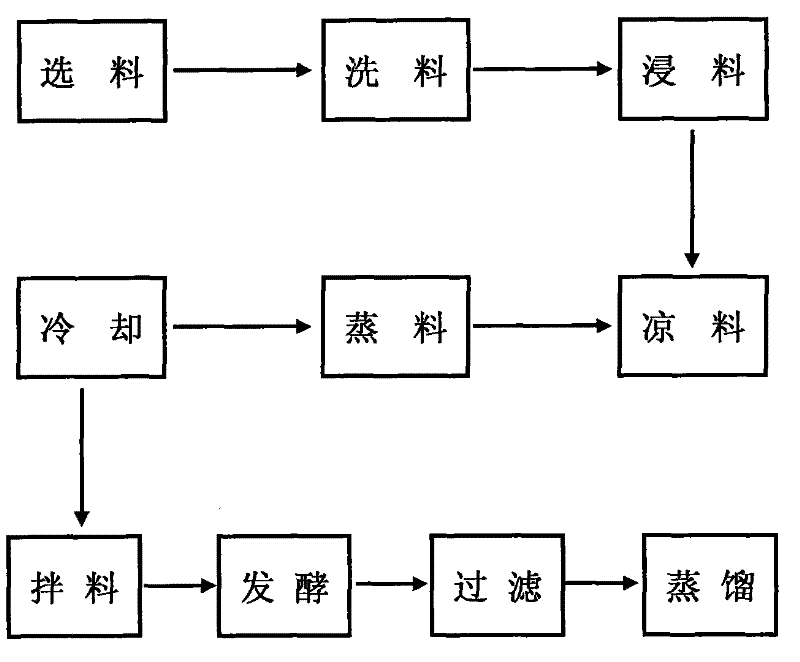

Image

Examples

Embodiment 1

[0008] see figure 1 , a kind of manufacture method of glutinous rice wine of blood, comprises the following process that carries out successively: material selection, washing material, steeping material, cooling material, steaming material, cooling, mixing material, fermenting, filtering and distilling; The raw materials are: 80 kg of blood glutinous rice, 10 kg of japonica rice, and 10 kg of white glutinous rice. Mix the above raw materials evenly; during the washing process, wash the above selected raw materials in clean water; The temperature is 10~25℃, and the soaking time is 4 hours; during the cooling process, filter the soaked raw materials; during the steaming process, the raw rice is completely steamed, and there is no hard core when touched by hand; during the cooling process , take out the steamed rice and cool it to about 40°C; during the mixing process, stir the cooled cooked rice and koji evenly to form clinker, the cooked rice weighs 143 kg, and the koji weighs ...

Embodiment 2

[0010] Substantially the same as implementation example one, its feature is: also added flavor flavoring agent and 5 kilograms of commercially available white sugar in the mixing process.

[0011] After repeated tests by the inventor, it is found that, except for the same process as the implementation example one, the difference can still use the method to make blood glutinous rice wine as long as the following five conditions are met simultaneously: 1. the above-mentioned selection The proportion of raw materials selected in the material process is: blood glutinous rice accounts for more than 50% of the total weight, japonica rice accounts for less than 20% of the total weight, and the others are white glutinous rice or black glutinous rice; The temperature is 10~25°C, and the soaking time is 3~8 hours; ③During the cooling process, the steamed rice is taken out and cooled to 30~70°C; ④In the mixing process, the Stir the cooled cooked rice and koji evenly to form clinker. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com