Sectionalized heat absorption, sectionalized compression and sectionalized expansion gas compression type heat pump

A technology of gas compression and segmental compression, which is applied in heat pumps, lighting and heating equipment, refrigeration components, etc., and can solve the problems of high compression ratio of compressors and low performance index of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

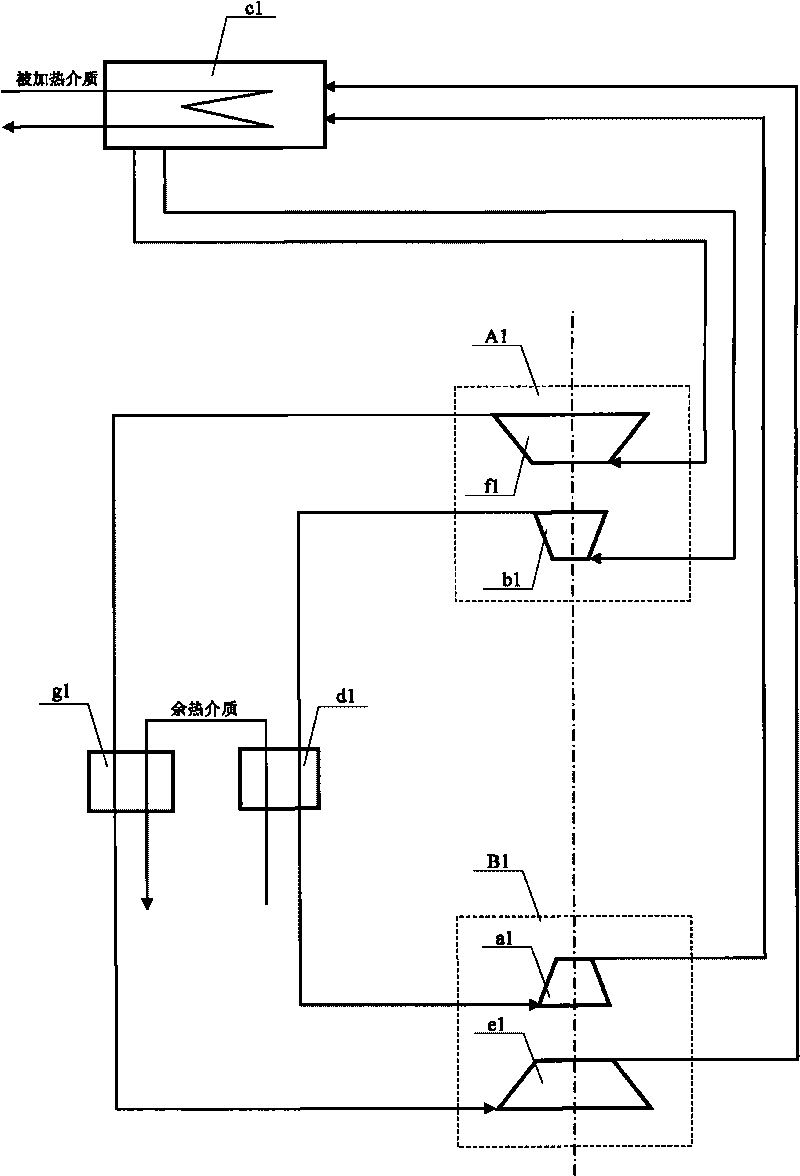

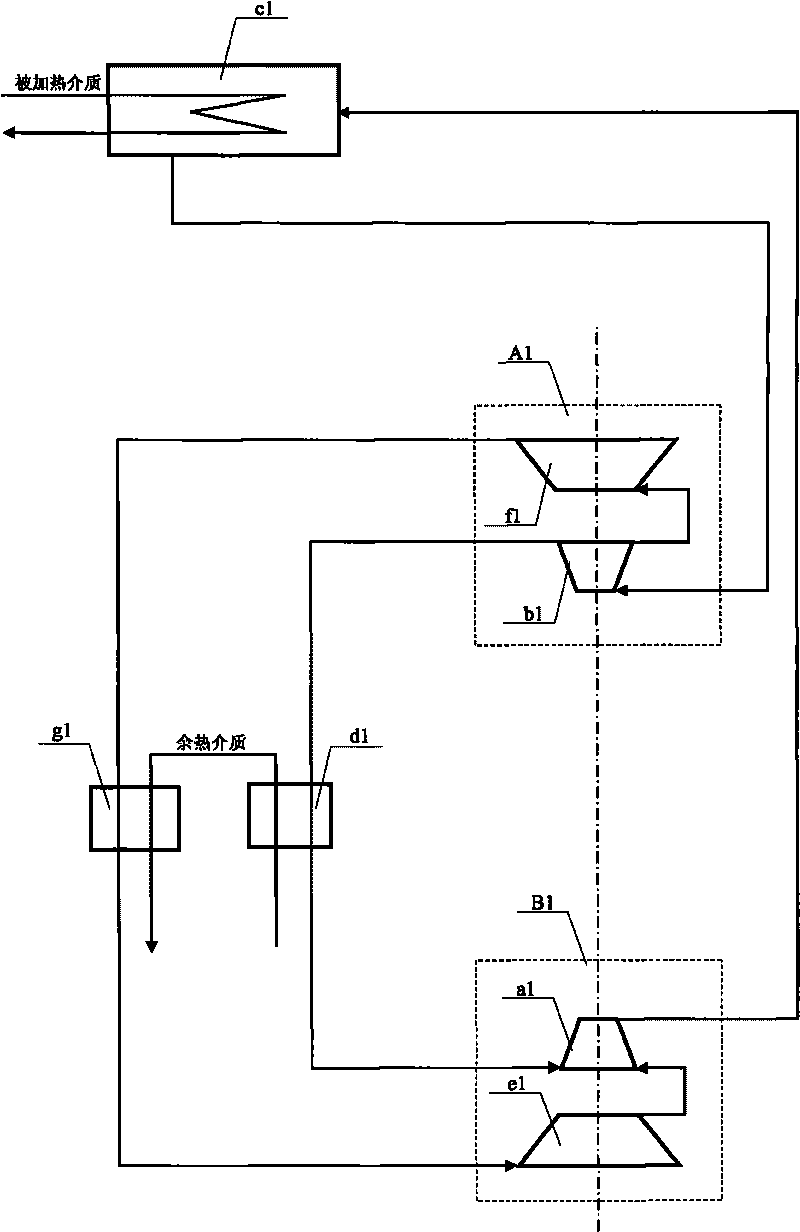

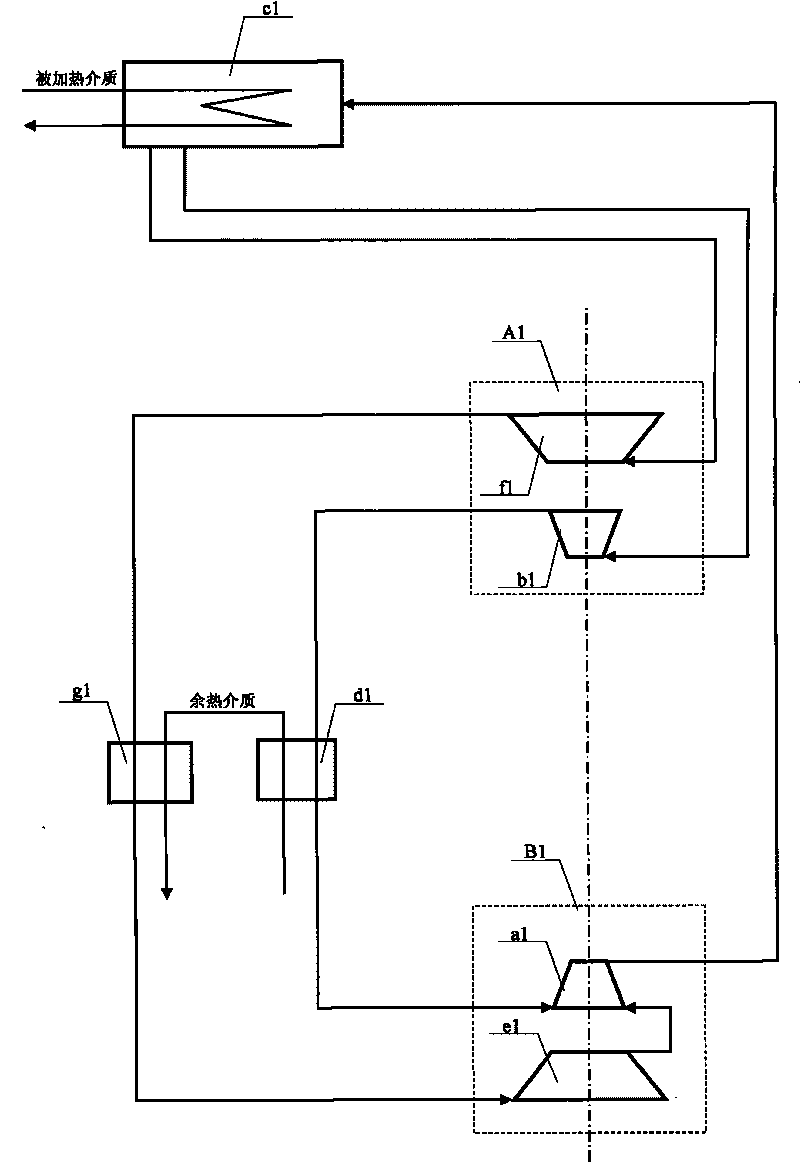

[0050] figure 1 The shown two-stage heat absorption-two-stage compression-two-stage expansion gas compression heat pump, in which the first compressor and the second compressor respectively provide compressed gas to the heater, is realized in this way:

[0051] ① Structurally, it consists of the first compressor a1, the first expander b1, the heat supplier c1, the first heat exchanger d1, the second compressor e1, the second expander f1 and the second heat exchanger g1; A heat exchanger d1 has a refrigerant medium pipeline connected to the first compressor a1 and a waste heat medium pipeline connected to the outside, the first compressor a1 also has a refrigerant medium pipeline connected to the heater c1, and the heater c1 also A refrigerant medium pipeline communicates with the first expander b1 and a heated medium pipeline communicates with the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com