Abrasion test method for determining rational hardness pairing of friction pair

A test method and friction pair technology, applied in the direction of testing wear resistance, etc., can solve the problem of not considering the influence of material hardness on friction and wear, and achieve the effect of feasible and effective method, easy implementation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

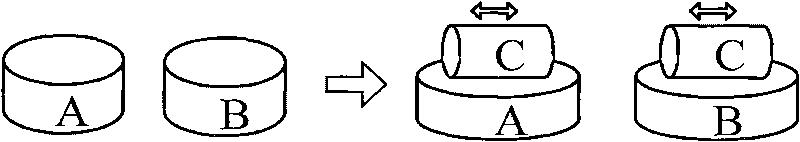

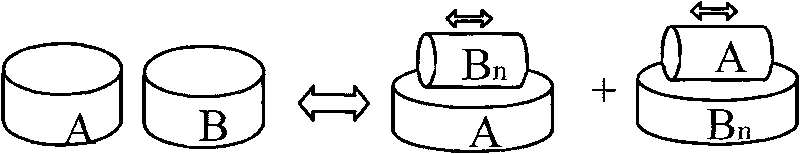

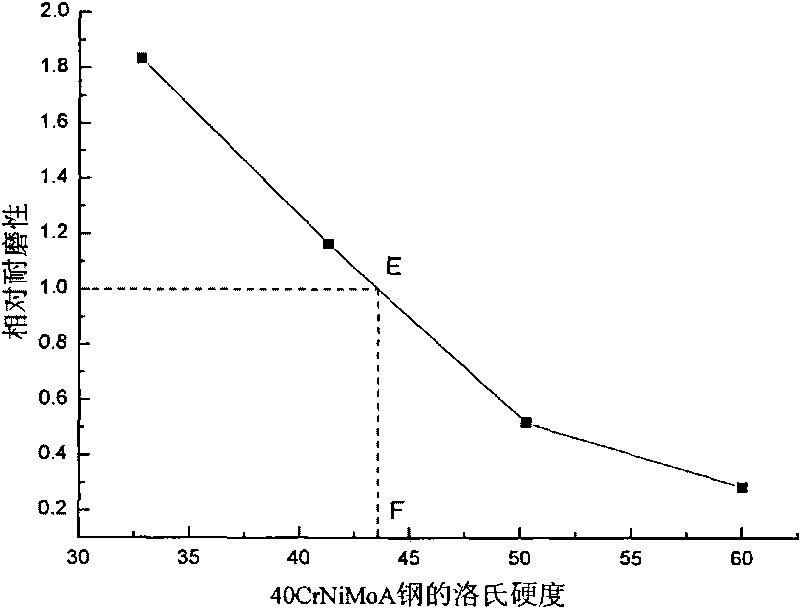

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto. The steel straight-profile toroidal worm pair in the mechanical track adjuster used by tracked vehicles, the worm and worm gear materials are made of alloy steel. When the pair of steel worm gear pairs adjust the tightness of the track, they are in the low-speed and heavy-load rotation condition; when there is no need to adjust the tightness of the track, there is a fretting state on the tooth surface. In actual use, often due to excessive wear on one side of the steel worm gear pair, the entire steel worm gear pair cannot reach the expected service life, so choosing a reasonable hardness pair is one of the methods to prolong the life of the worm gear pair.

[0027] The following are the specific steps of the wear test method for reasonable hardness matching of steel worm gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com