Variable-speed moving device of main contact and arc contact in arc extinguishing chamber

A motion device and arc-extinguishing chamber technology, applied in contact drive mechanism, high-voltage air circuit breaker, electrical components, etc., can solve the problems of lengthening the movement stroke of the main contact and increasing the operating energy, which is conducive to miniaturization and operation. The effect of energy reduction and length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

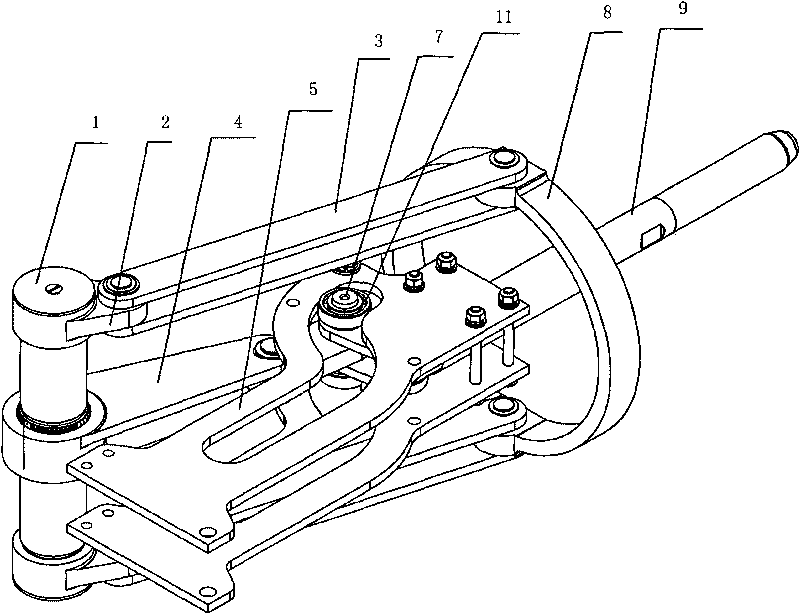

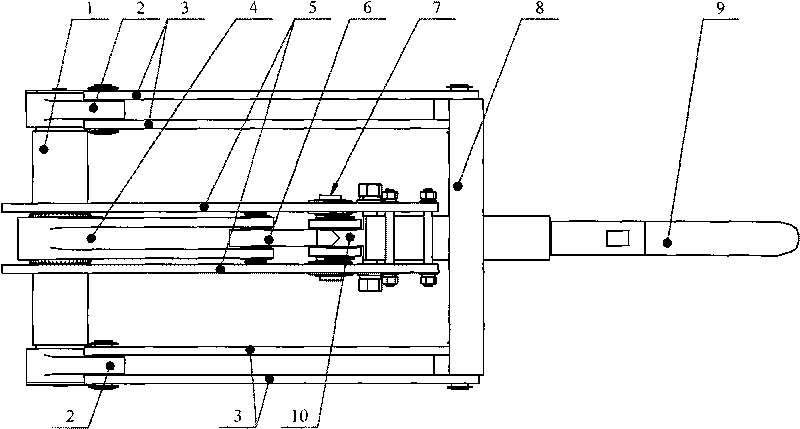

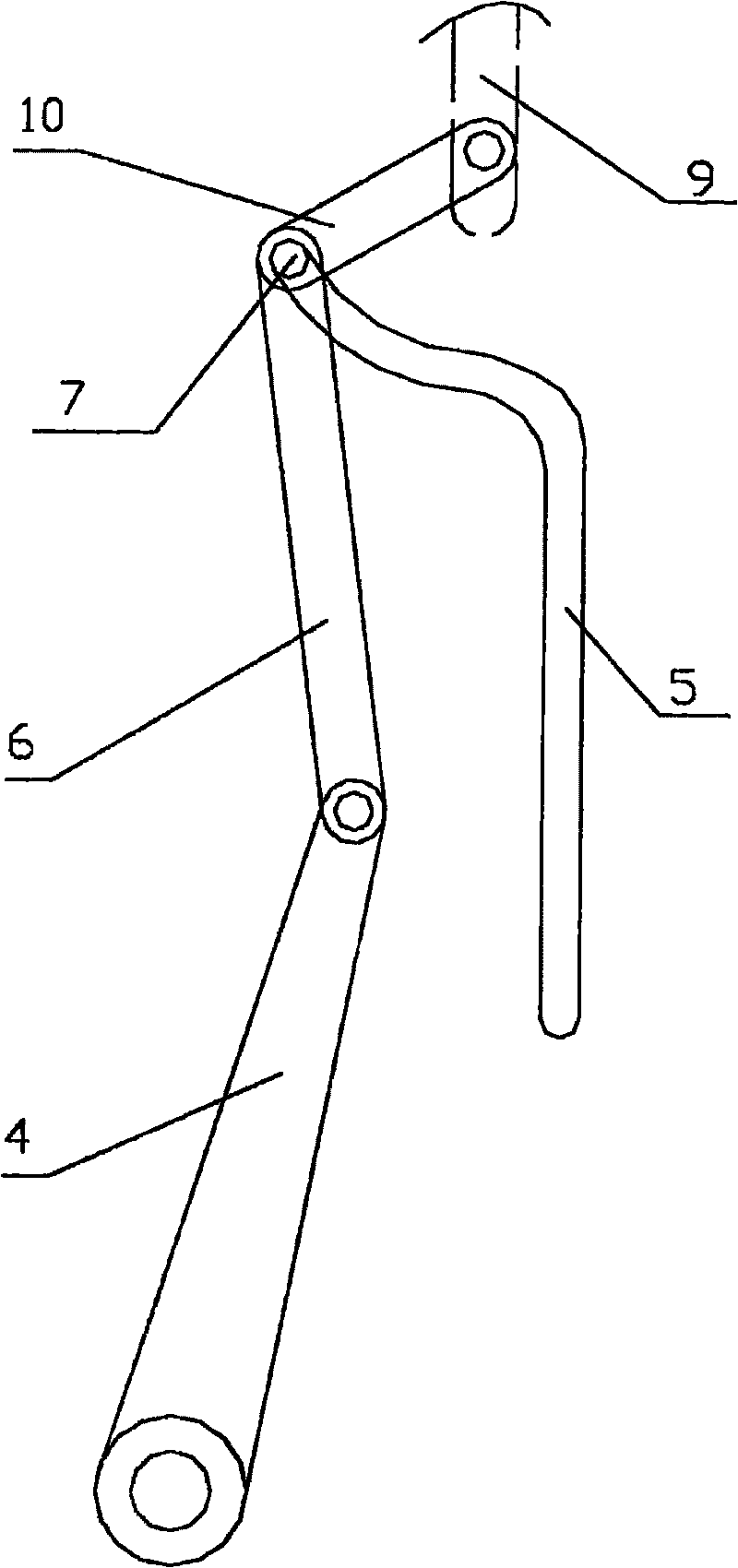

[0015] refer to figure 1 , 2 , is a different-speed movement device for the main and arc contacts in the arc extinguishing chamber, mainly including: a guide rail 5 fixed in the arc extinguishing chamber, a main shaft 1 installed in the arc extinguishing chamber, and two short crutches fixed at both ends of the main shaft 1 The arm 2 has two long connecting plates 3 corresponding to the two short crank arms 2, the long crank arm 4 is fixed in the middle of the main shaft 1, and the first short connecting rod 6, the second short connecting rod 10 and the arc contact are sequentially movably connected. head 9.

[0016] The two short crank arms 2 are movably connected to both sides of the main contact 8 through the corresponding two long connecting plates 3, forming a symmetrically arranged four-bar linkage mechanism, which is a crank linkage mechanism, which is used to independently drive the main contact 8 to move. .

[0017] The arcing contact 9 runs through the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com