Method for assembling clamp spring and retainer ring of starting motor, special clamp spring awl, clamp spring sleeve and assembly system

A technology of circlip collar and starter motor, which is applied to the assembly of special circlip cones, starter motor circlip collars, circlip cone sleeves and assembly systems, and can solve the problems of low efficiency, unguaranteed product quality, Failure and other problems, to ensure the assembly quality, prevent excessive deformation and failure of the circlip, and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

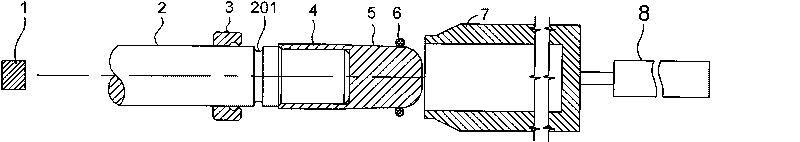

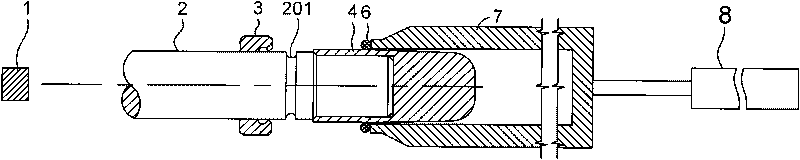

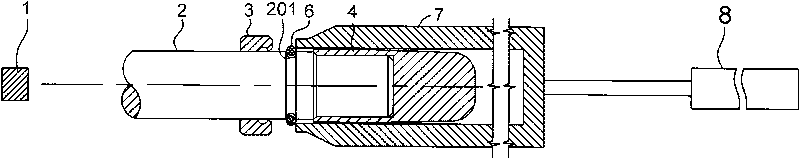

[0017] Such as Figure 5 As shown, there is a circlip groove 201 near the end of the armature shaft 2. The purpose of the method for assembling the starter motor circlip provided by the present invention is to accurately install the circlip 6 Locate in the ring groove 201, and then press the ring 3 on the ring 6, so that the ring 6 is pressed into the ring groove of the ring 3, so that the ring 3 is axially positioned on the Armature shaft 2. There is a certain matching gap between the collar 3 and the armature shaft 2 , so the collar 3 can be inserted into the armature shaft 2 normally.

[0018] Such as Figure 1 ~ Figure 4 As shown, the assembling method of this starter motor retaining ring of the present invention comprises the following steps:

[0019] 1) Set the collar 3 on the armature shaft 2, and install the snap ring cone 4 at the end of the armature shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com