Pulp cooking device and food processor with same

A food processor and pulp cooking technology, which is applied in the field of soybean milk machine and rice paste machine, can solve the problems of cumbersome operation, liquid juice cannot be separated, waste, etc., and achieve the effect of not easy to paste tube, fast speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

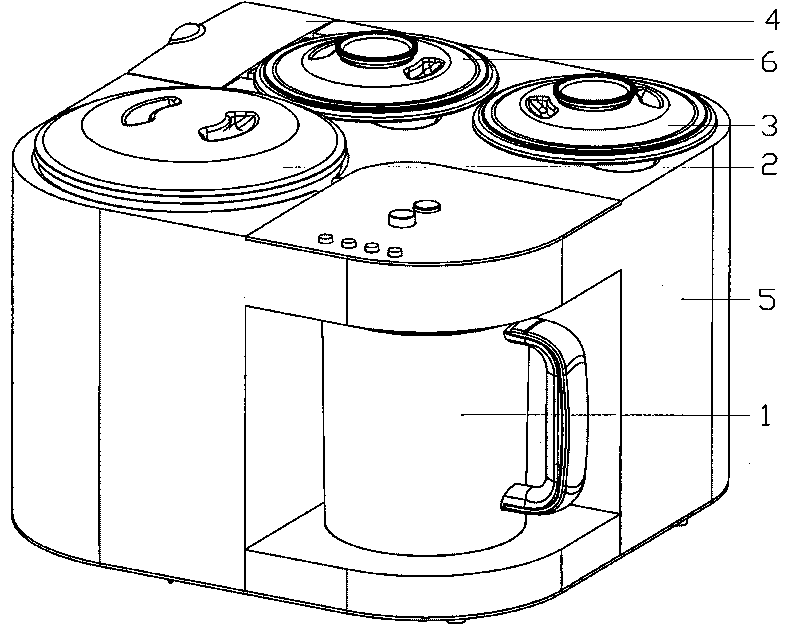

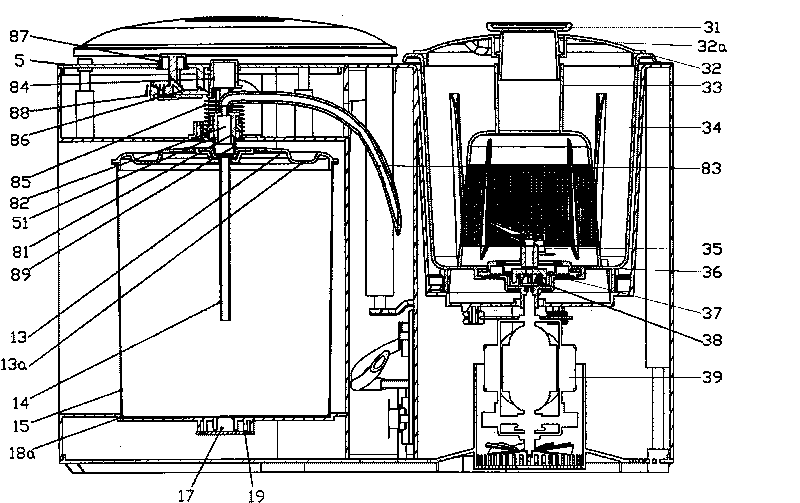

[0035] figure 1 The shown DE food processor includes a main engine 5, a crushing device 3, a slag juice separation device 2, a water supply device 4, a pulp cooking device 1, etc., and a spare rice paste cup 6 can also be equipped.

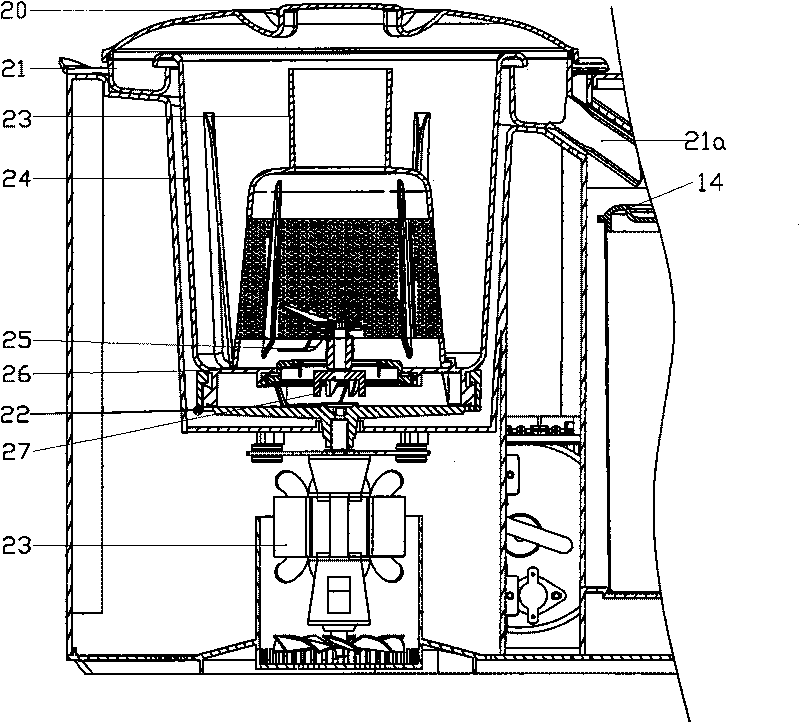

[0036] figure 2 yes figure 1 The sectional view of middle crushing device 3 and pulp cooking device 1 position, as figure 2 The crushing device 3 shown in the right half includes a stirring cup cover 32, a measuring cup 31, a stirring cup 34, a filter screen cover 33, a blade 35, a knife holder 36, an upper connector 37, a lower connector 38, and a motor. There is a material inlet 32a in the middle of the stirring cup cover 32, the measuring cup 31 is reversed and inserted into the material inlet 32a, the lower end of the filter screen cover 33 is rotated and inserted into the mixing cup 34 to fix, and the upper port of the filter screen cover 33 is connected with the material inlet 32a , motor 9 selectively drives blade 35 to rotate by upper...

Embodiment 2

[0045] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the centering device is a boss 18b arranged at the bottom of the main body, and a positioning pit 15a is provided on the bottom surface of the pulp cup 15 opposite to the boss 18b. The boss 18b, the positioning pit 15a and the steam pipe are on the same axis. Other structures are all the same as in Example 1.

Embodiment 3

[0047] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the centering device is at least three positioning columns 18c arranged at the bottom of the main body, and the positioning columns 18c are distributed around the central axis of the steam pipe, and the cooking cup 15 placed in the area formed by the positioning post 18c. Other structures are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com