Precision anti-aluminum running die-casting device

An aluminum die-casting and anti-running technology, which is applied in the field of die-casting devices, can solve problems such as increasing the size of the cavity 9, increasing the gap size, and swelling, and achieves the effects of avoiding the phenomenon of aluminum running, reducing the fit gap, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is described in detail.

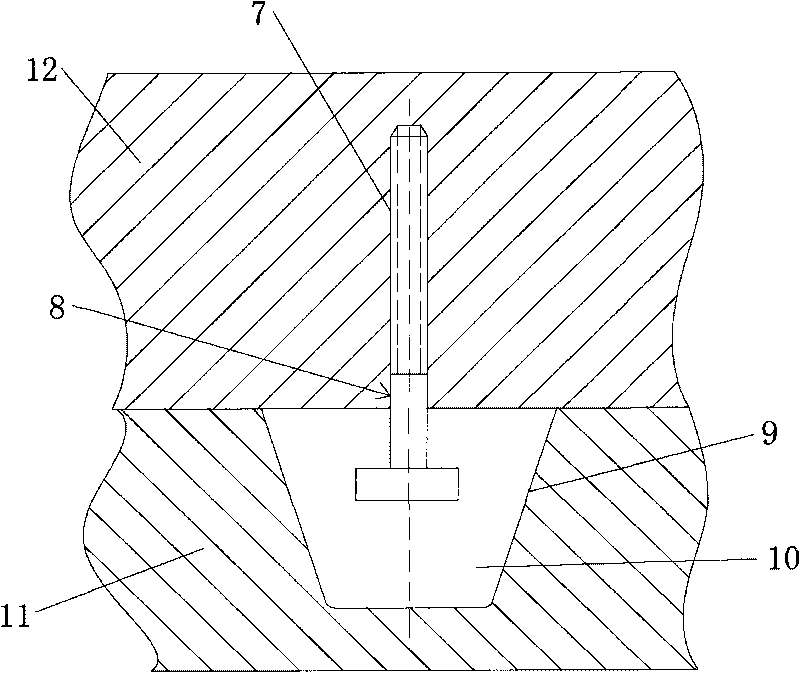

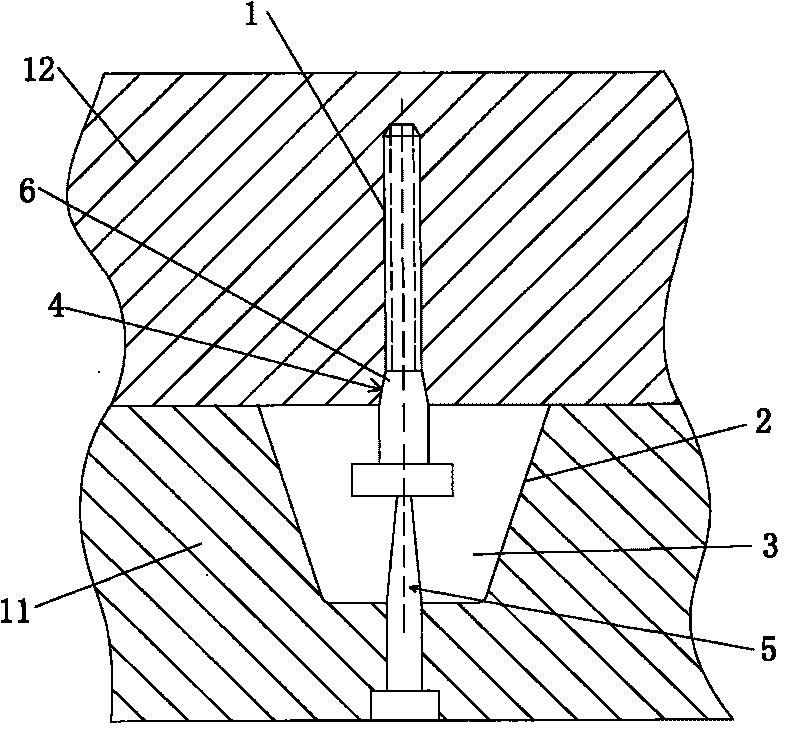

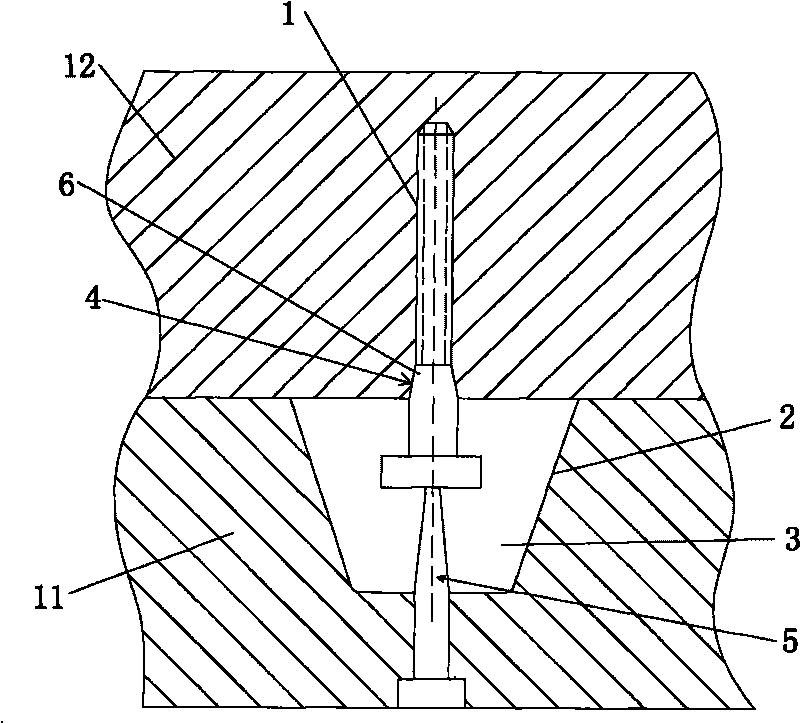

[0019] Such as figure 2 Shown:

[0020] A precision anti-running aluminum die-casting device, comprising a main mold and an insert fixed on the main mold, the main mold is composed of a fixed mold 11 and a movable mold 12 matched with the fixed mold 11, and the insert is inlaid On the fixed mold 11 , the mating surface 4 of the insert and the fixed mold 11 is non-planar, and the aluminum liquid 3 is filled in the cavity 2 of the fixed mold 11 . One end of the insert is inlaid on the fixed mold 11, the other end of the insert extends in the opposite direction and the end face of the joint with the fixed mold 11 is the mating surface 4, and the mating surface 4 of the fixed mold 11 and the insert is a tapered surface , the included angle between the conical surface and the horizontal plane is 2°-10°. On the one hand, this structure can ensure good cooperation between the insert and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com