Wire drawing machine

A wire drawing machine and frame technology, which is applied to machine tools, grinders, metal processing equipment and other directions suitable for grinding workpiece planes, can solve the problems of unnatural wood grain three-dimensional effect, unsatisfactory wire drawing effect, and insufficient grain width, etc. Achieving the effect of strong three-dimensional wood grain, widening lines and increasing tensile force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

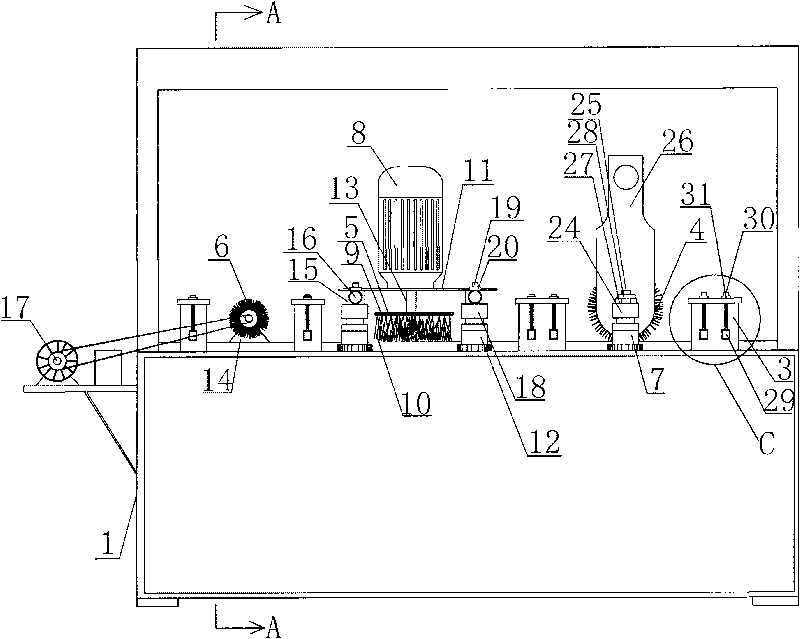

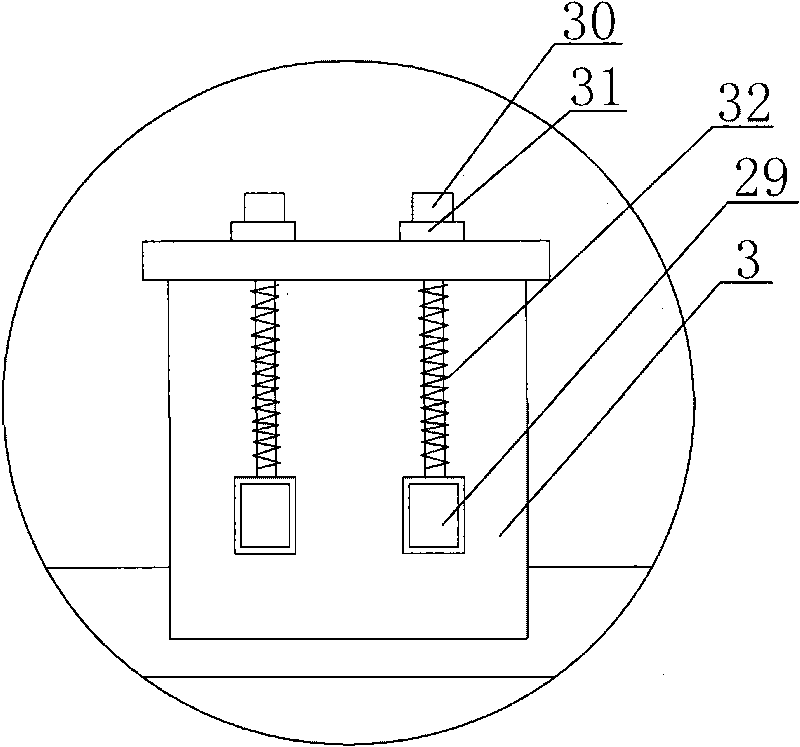

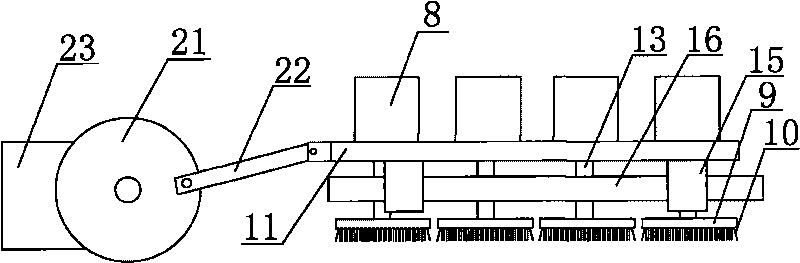

[0037] Embodiment: a kind of wire drawing machine, comprises frame 1, is installed with the plank transmission system driven by transmission motor on the end face of frame 1; figure 1 , Figure 4 , Figure 6 As shown, the plank transmission system includes transmission wheels 33 arranged on both sides of the upper end of the frame and transmission belts 34 wrapped around the two transmission wheels 33. The outer surface of the transmission belt 34 is densely covered with grid-like grooves 40 . The transmission wheel 33 is driven to rotate by a transmission wheel motor 35 arranged at the bottom of the frame 1 to control the transmission belt 34 . The two ends of described transmission wheel 33 are installed on the transmission wheel installation block 36, and described transmission wheel installation block 36 lower ends are connected with installation block elevating mechanism, and described installation block elevating mechanism is worm gear transmission mechanism, and it co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com