Tray loading structure for cylindrical workpieces

A technology of cylinders and workpieces, which is applied in the field of production and packaging of cylindrical workpieces, can solve the problems of affecting production efficiency, operator injury, and non-sorting of cylindrical workpieces, and achieves the effect of convenient statistics and analysis and orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

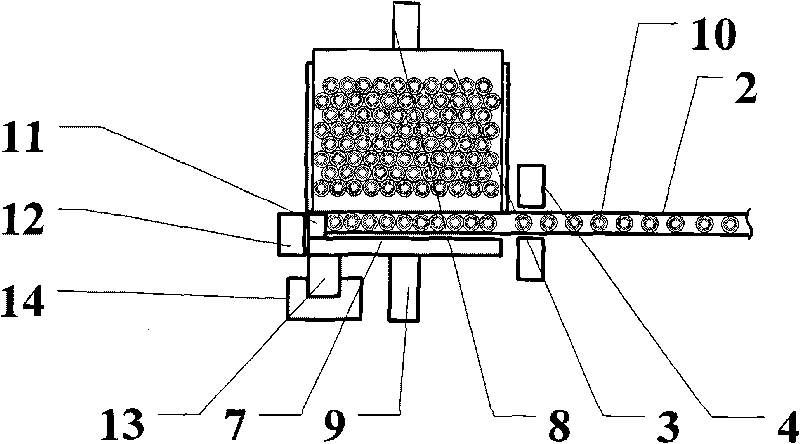

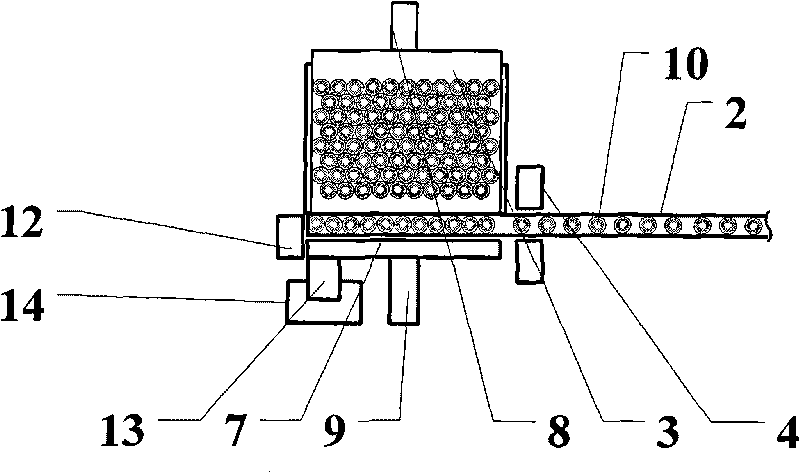

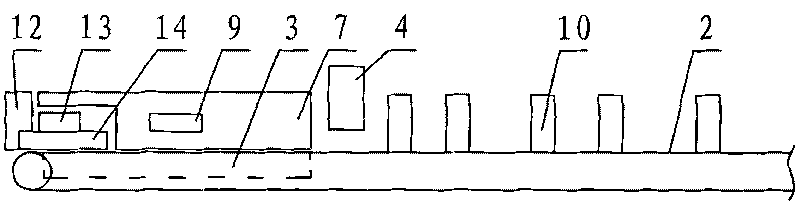

[0016] When implemented, such as Figure 1 to Figure 3 As shown, a plate-loading structure of a cylindrical workpiece is structured as follows: one side of the end of the conveyor belt 2 is horizontally provided with a twitchable pad 3, and the other side is provided with a pusher whose length matches the width of the twitchable pad 3. Rod 7, the upper surface of the movable pad 3 is a smooth plane and one side is connected with a pad pneumatic device 8, the push rod 7 is provided with a push rod pneumatic device 9 on the opposite side of the conveyor belt 2, which pushes When the rod pneumatic device 9 acts, it can drive the push rod 7 to push the cylindrical workpiece 10 above the conveyor belt 2 to the movable backing plate 3; There is a counting device 4; a movable stopper 11 and a fixed stopper 12 are sequentially arranged above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com