Biomass storage feeding device

A feeding device and biomass technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of bridges, unable to feed normally, and achieve the effects of low cost, simple structure and easy improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

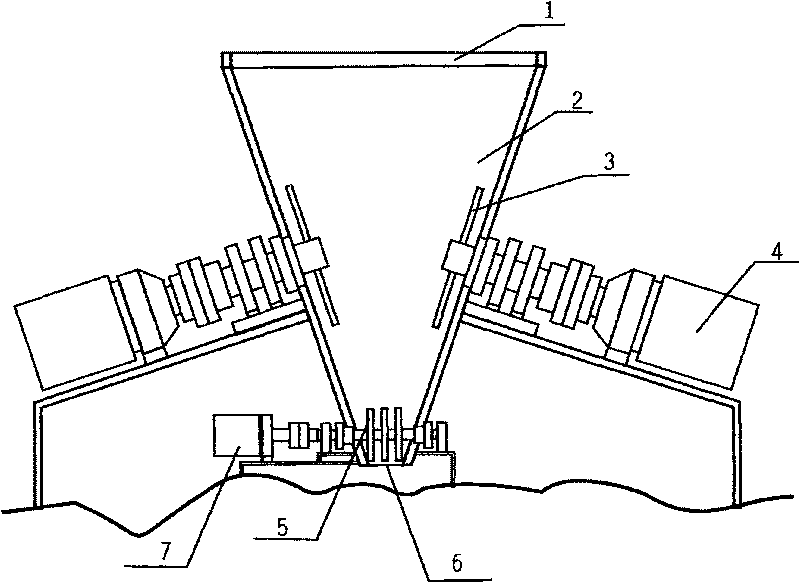

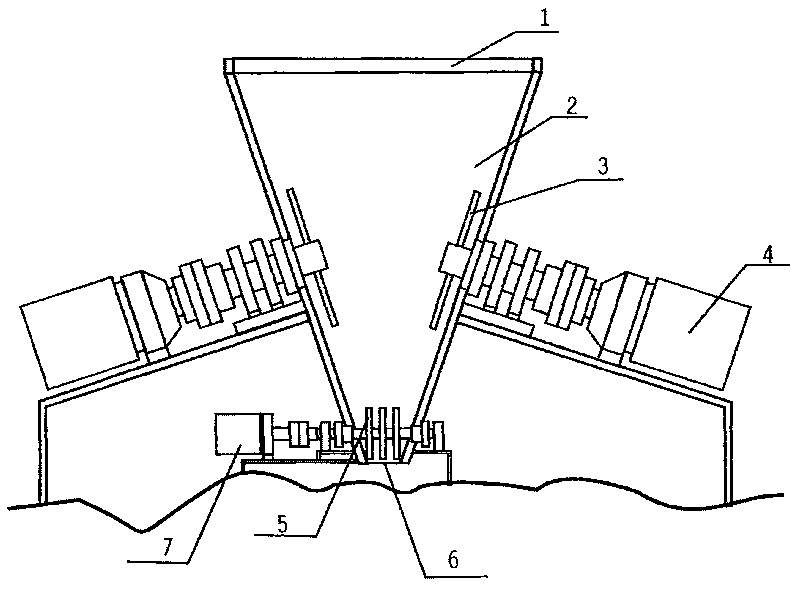

[0009] refer to figure 1 , the biomass storage and feeding device includes a storage room 2, the storage room 2 is provided with a material inlet 1 and a material outlet 6, and a driving rod 3 is installed along the inner side wall of the storage room 2, and the driving rod 3 passes through the shaft and the device. The material shifting motor 4 outside the storage room 2 is connected; in the discharge port 6 of the storage room 2, a loose material rod 5 is also provided, and the loose material rod 5 links to each other with the loose material motor 7 located outside the storage room discharge port through a shaft.

[0010] When in use, when the biomass fuel enters the storage chamber 2 from the feed port 1 and forms a pile, start the motor 4 and the motor 7, and the lever 3 will rotate along the side wall of the storage chamber 2, destroying its "bridge pier...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap