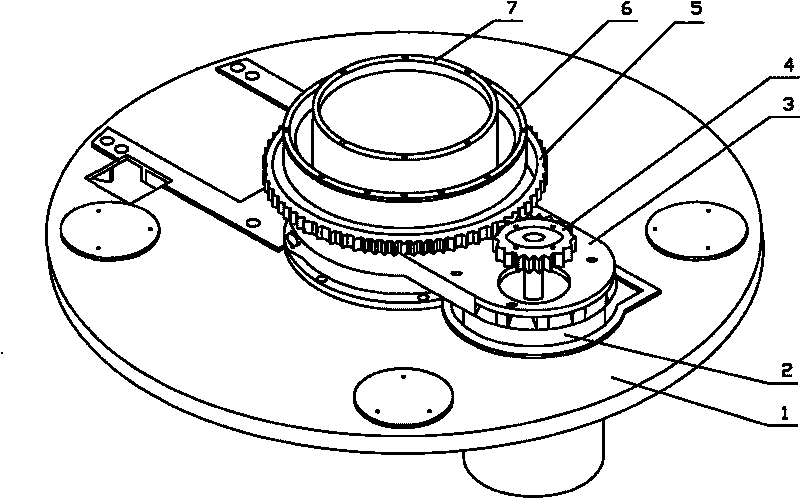

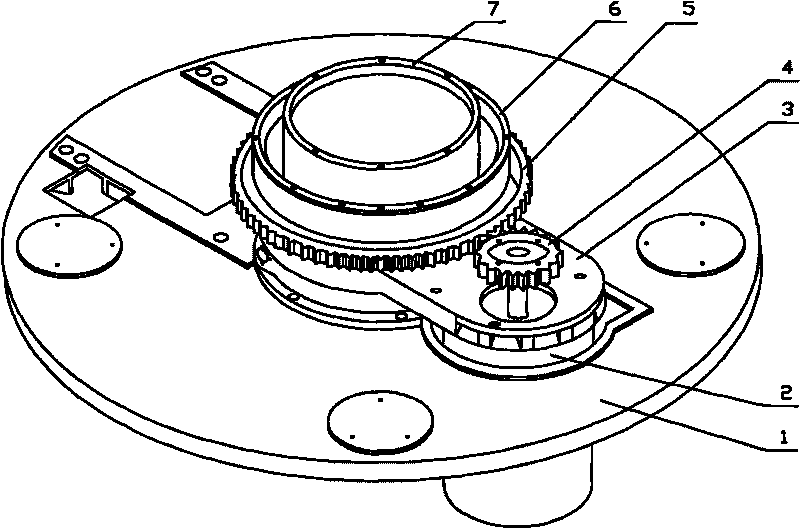

Direct connection transmission structure for circular weaving machine

A direct-connection, circular loom technology, applied in looms, textiles, textiles, and papermaking, can solve problems such as improper adjustment of the coaxiality of the coupling, affecting the textile quality of the circular loom, and being unfavorable for equipment maintenance. Achieve the effect of convenient maintenance, compact structure and short drive chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The direct-connected transmission structure of the circular loom shown in the accompanying drawing is installed at the bottom of the circular loom, and it includes a base 1, a motor 2, a bracket 3, a driving gear 4, a driven gear 5, a shuttle bed bearing seat 6 and a seat Cover 7. The base 1 is a plate-shaped member, and the middle part of the board is positioned to install the seat cover 7 standing upright. The bracket 3 is fitted with the middle section of the seat cover 7 with a large hole end and is fixedly connected to form a cantilever. The shuttle The bed bearing seat 6 is a cylindrical component, the bottom end of which is coaxially fitted and connected with the driven gear 5 and is in clearance fit with the seat cover 7. In the present invention, a through hole is provided on the cantilever plane of the bracket 3 to communicate with the side of the base 1. The holes are coaxially opposite, the motor 2 axially passes through the side through hole of the base 1 fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap