Internal liner of drainage pipe or dirt discharge pipe for operation with water and construction method thereof for operation with water

A technology of water-carrying operation and construction method, which is applied in the direction of sewer pipe system, waterway system, water supply device, etc., and can solve the problems that the inner lining of water-carrying construction, branch pipe connection needs to be excavated, and the technical level of workers is required to be high. , to achieve the effect of simple and reasonable structure, small footprint and low technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

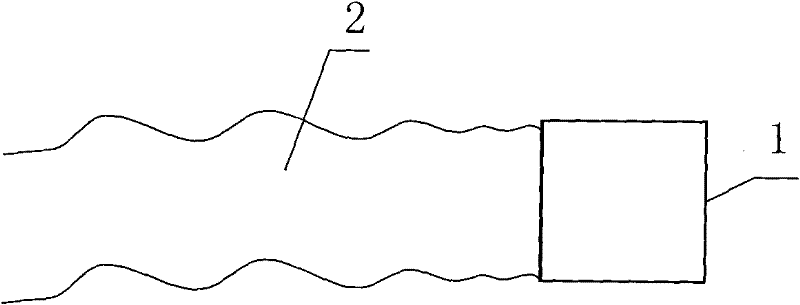

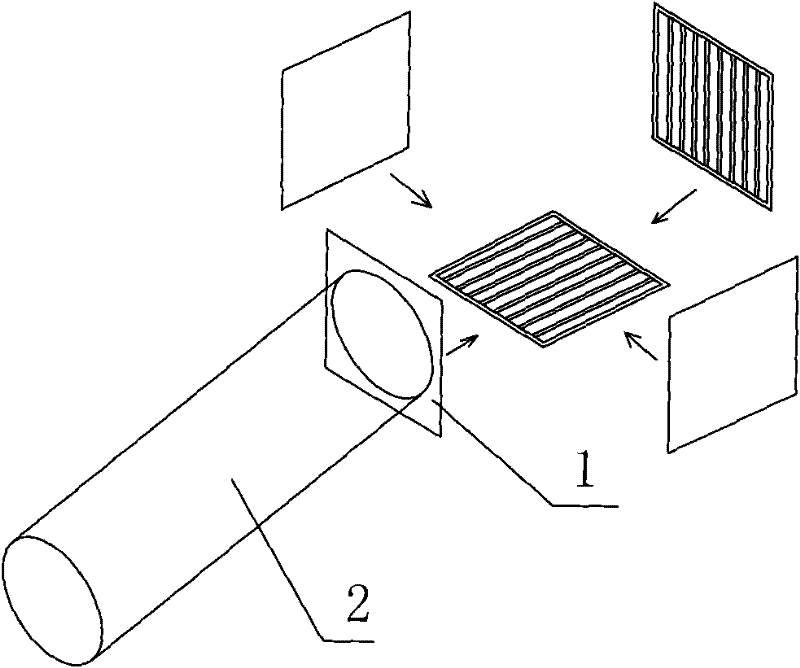

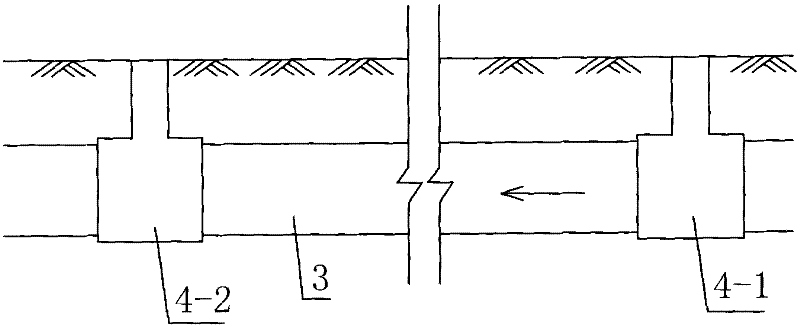

[0043] Such as figure 1 , figure 2 As shown, the drainage pipe or sewage pipe lining for water-carrying operation according to the present invention includes a caisson 1 that can be lowered along the inspection well to the interior of the drainage pipe or sewage pipe 3 that needs to be lined, and one end is sealed and fixed on the side wall of the caisson 1 The rubber liner 2 connected to the interior of the caisson 1, the cross-sectional structural size and height of the caisson 1 are the same as the cross-sectional structural size and height of the inspection well, and the rubber liner 2 is filled with water. The cross-sectional structural size and pipeline length are the same as those of the drainage pipe or sewage pipe 1 that needs to be lined. The caisson 1 and the rubber lining pipe 2 are in a sealed connection. Upstream manhole 4-1 upstream of pipe or blowdown pipe 3. The side wall of the caisson 1 is correspondingly provided with an installation opening for the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com