Unwinding machine of strip pickling line

A technology of pickling line and unwinding machine, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of heavy maintenance workload, affecting production efficiency, and hindering the rotation space of special wrenches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

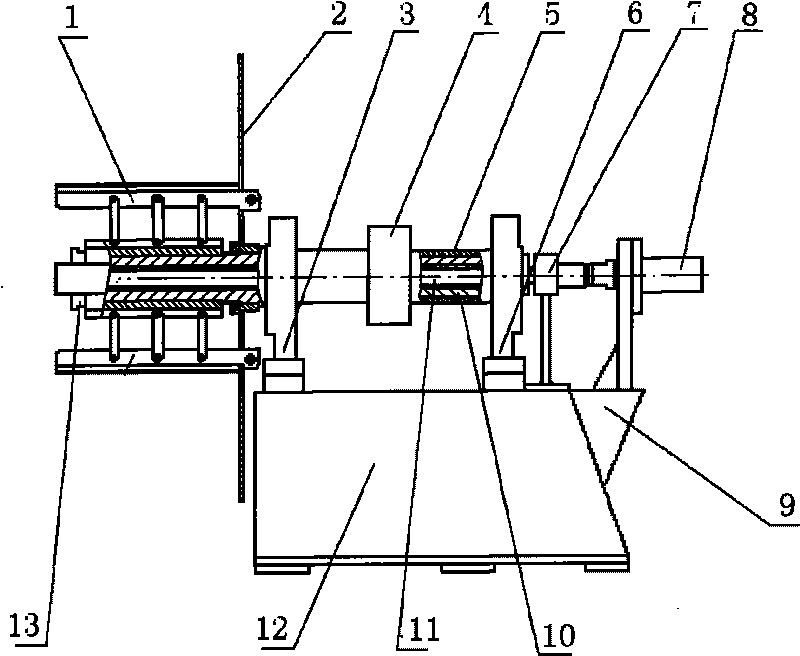

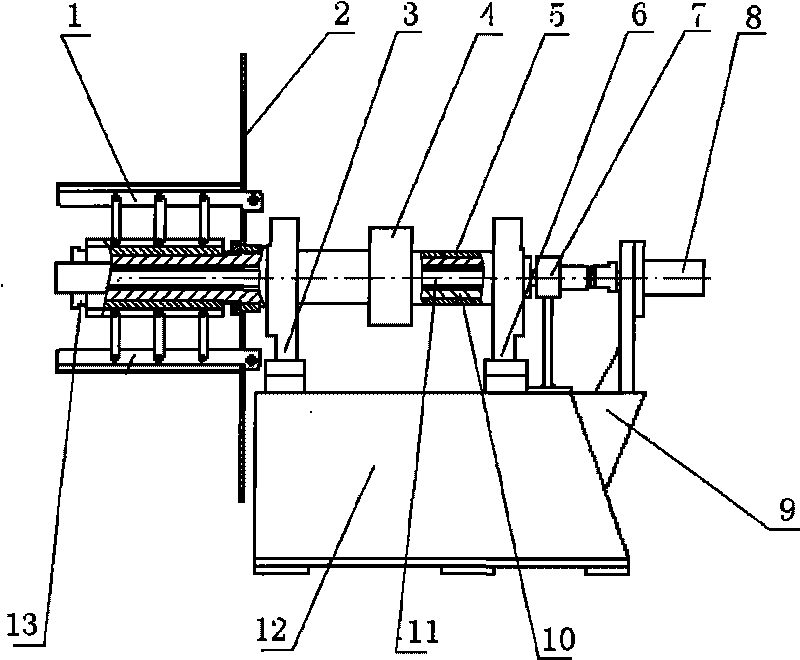

[0012] Such as figure 1 As shown, a strip pickling line unwinding machine includes a machine base 12, an auxiliary support 9, a first bearing seat 3, a second bearing seat 6, a main shaft 10, a sliding sleeve 7, an oil cylinder 8, a positioning sleeve 5, and a brake 4 , baffle plate 2, pull rod 11, quadrangular pyramid reel 1 and end cover 13, the first bearing seat 3 and the second bearing seat 6 are fixed on the machine base 12, the first bearing seat 3 is adjacent to quadrangular pyramid drum 1, The auxiliary support 9 is located on the upper part of one side of the machine base 12, the oil cylinder 8 is fixed on the auxiliary support 9, the oil cylinder 8 is connected to the hydraulic system of the strip pickling line, and the main shaft 10 is installed on the first bearing seat 3 and the second bearing seat 6 Above, the main shaft 10 is a hollow shaft, and there is a pull rod 11 passing through the main shaft 10, one end of the pull rod 11 is connected with the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com