Water plowing type aerator

A technology of aeration machine and water cultivation, applied in water aeration, water/sludge/sewage treatment, animal husbandry, etc., can solve the problems of low oxygenation capacity, low power, high power consumption of oxygenation, etc., to achieve Save energy, reduce investment costs, and improve water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

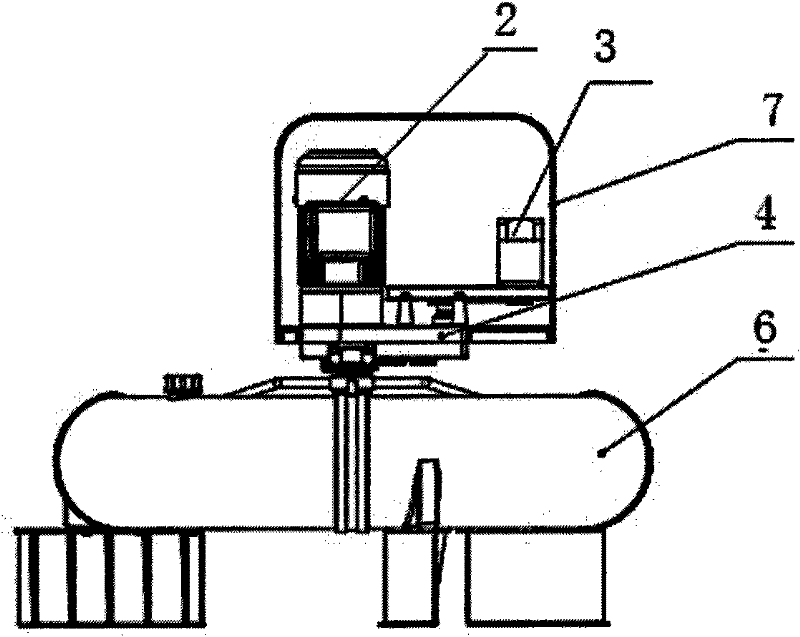

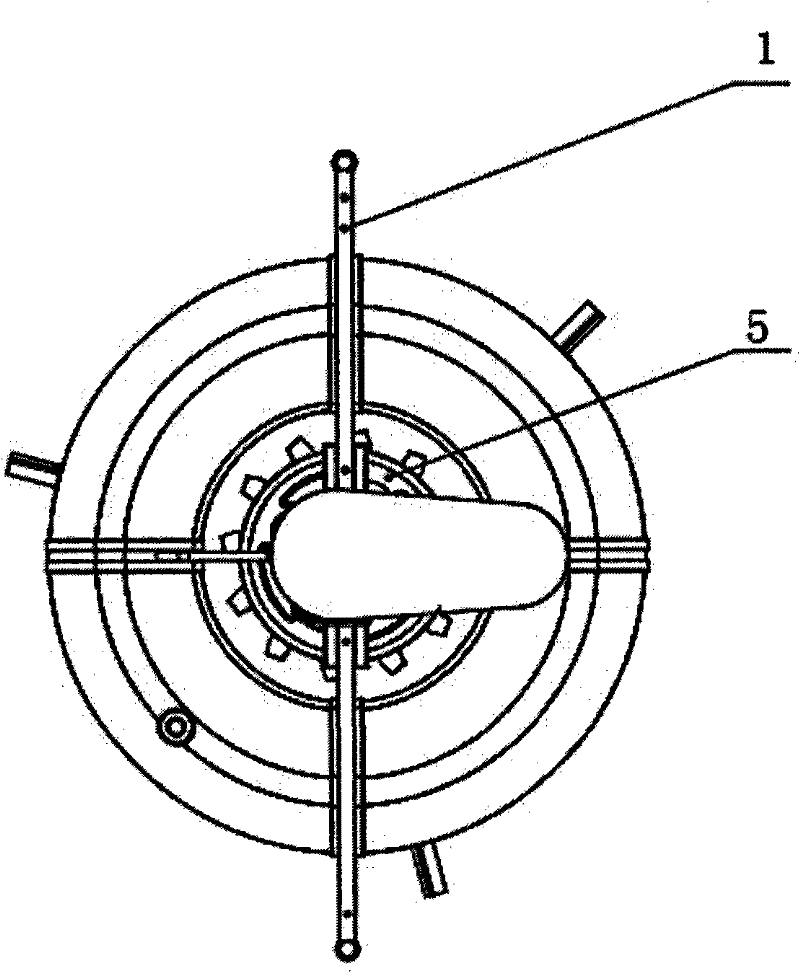

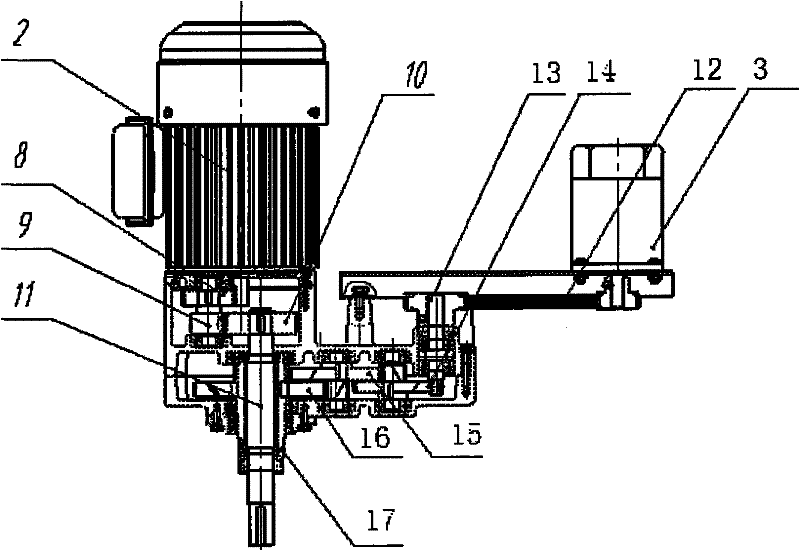

[0013] Such as Figure 1-3 As shown, the tillage type aerator includes a bracket 1, a main motor 2, an auxiliary motor 3, a transmission 4, an impeller 5 and a floating blade 6, and a transmission 4 is installed on the bracket 1, and the transmission 4 includes a main and an auxiliary Input shafts 8, 13, main and auxiliary output shafts 11, 17, two-stage reduction mechanism and four-stage reduction mechanism, the main input shaft 8 is connected to the main output shaft 11 through a two-stage reduction mechanism, and the auxiliary input shaft 13 is connected to the secondary through a four-stage reduction mechanism Output shaft 17; the reduction mechanism includes a transmission gear shaft, an intermediate gear and an output gear, the transmission gear shaft is connected to the input shaft, the transmission gear shaft meshes with the output gear through the intermediate gear, and the output gear is connected to the output shaft; the main and auxiliary input shafts of the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com