Operation method of circulating fluidized-bed boiler

A technology of circulating fluidized bed and fluidized bed boiler, which is applied in the direction of fluidized bed combustion equipment, combustion method, and fuel burned in a molten state, to achieve the effect of saving equipment maintenance costs and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

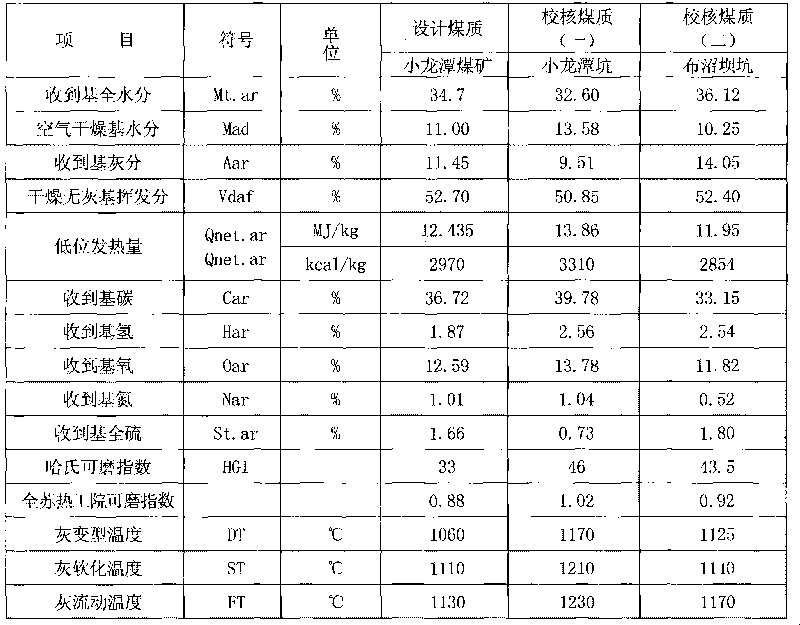

[0009] The 300,000-kilowatt circulating fluidized bed boiler uses lignite from the Xiaolongtan Coal Mine in Yunnan as coal, and the coal quality information is shown in the table below:

[0010]

[0011] The coal conveying system has been technically transformed, and the eight cage-type fine crushers (large and small) of the coal conveying secondary crushing system have been dismantled to crush the coal particle size to less than 50mm and send it directly into the furnace. The lower bed pressure reaches 11KPa, and the residence time of coal particles in the furnace is 20min. It not only saves the power consumption of the factory, but also optimizes the control of the bed pressure and bed temperature of the 300,000-kilowatt circulating fluidized bed boiler, ensuring the safe and long-term operation of the 300,000-kilowatt circulating fluidized bed boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com