Method for detecting surface defects of mechanical parts based on image texture and fractal dimension

A technology of fractal dimension and mechanical parts, applied in image analysis, image data processing, measuring devices, etc., can solve problems that do not conform to the actual observation of the human eye, and achieve simple and easy actual observation of the human eye and meet the actual observation of the human eye Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for detecting surface defects of mechanical parts based on image texture and fractal dimension comprises the following steps:

[0028] Step (1), pre-processing the mechanical parts to be tested, the specific method of pre-processing is to first apply black ink to the surface of the part to be tested, and after the ink fills the pores on the surface of the part to be tested, wipe the surface of the part with a dry cloth;

[0029] Step (2), placing the pre-processed mechanical parts on the conveyor belt, using a CCD image acquisition system to collect images of the surface of the part to be tested, to obtain a texture image of the surface of the part;

[0030] Step (3), calculate the fractal dimension and the porosity of the texture image;

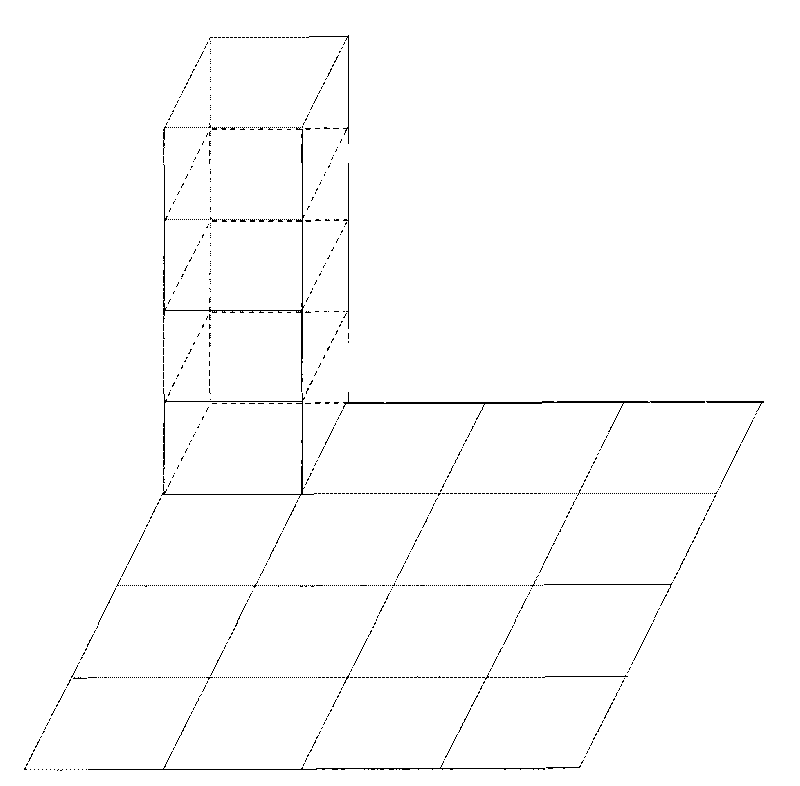

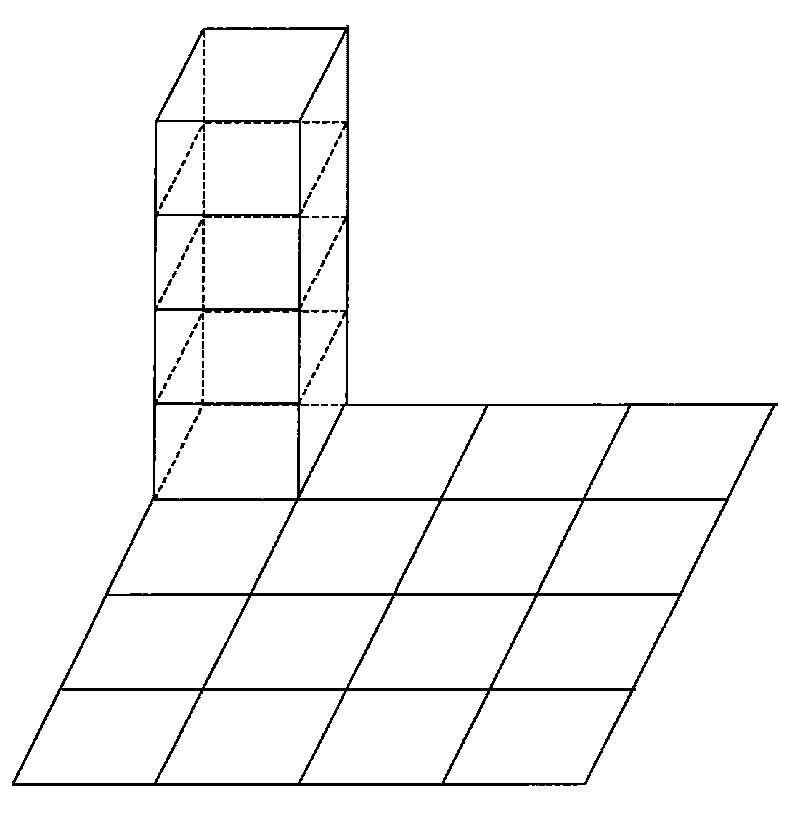

[0031] The method to calculate the fractal dimension of the texture image is:

[0032] The surface image of the mechanical part is extended to several zero rows or several zero columns at the corresponding boundaries so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com