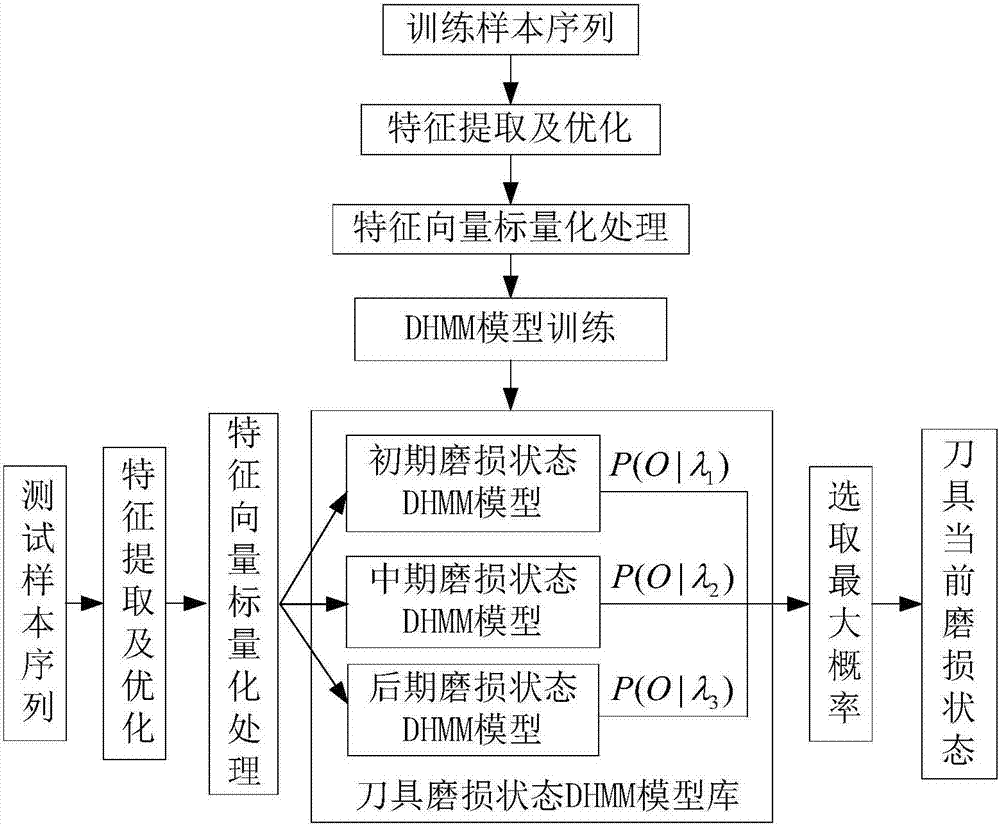

Monitoring method based on image features and LLTSA algorithm for tool wear state

A technology of tool wear and wear state, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problem of large image feature dimension, important information of feature vector is not fully used, and has not been reported in literature and practice. application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

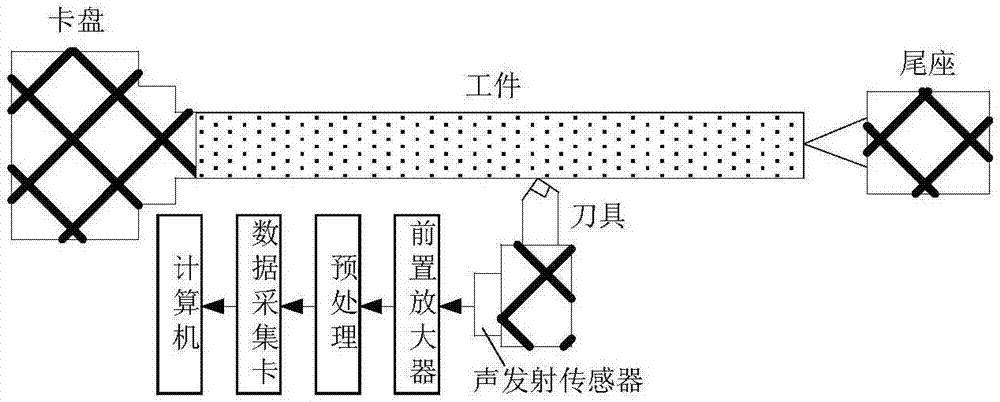

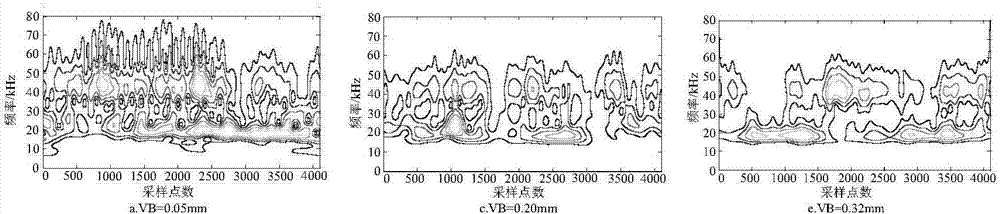

[0101]On a common lathe of CA6140, a YT15 carbide tool is used to cut T10 carbon tool steel. The R15-ALPHA resonant acoustic emission sensor is adopted, with a center frequency of 150KHz and a frequency range of 50-200KHz. The bandwidth of the preamplifier is 20-1200kHz, and the gain is selected as 40dB. Use PXI-6366 data acquisition card to complete data acquisition, and the sampling frequency is 2MHz. According to the orthogonal experiment method, the experimental program was designed, and 27 different cutting parameter combinations were selected to collect the acoustic emission signals during the machining process of the tool in three different wear states, and a total of 150 sets of signals were obtained. Experimental method: For a certain cutting condition, take a new blade 1 for a cutting experiment, stop after 10 seconds of cutting to collect data between 6 and 10 seconds, remove the blade, and measure the VB value (flank wear); replace a new blade 2, Cut for 20s unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com