Substation automation system (SAS) with insulation on-line monitoring function for high voltage electric power equipment

A technology for substation automation and high-voltage power equipment, which is applied in the direction of electric power measurement, electric variable measurement, and electricity measurement through current/voltage, and can solve problems that do not cover the online monitoring function of high-voltage power equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

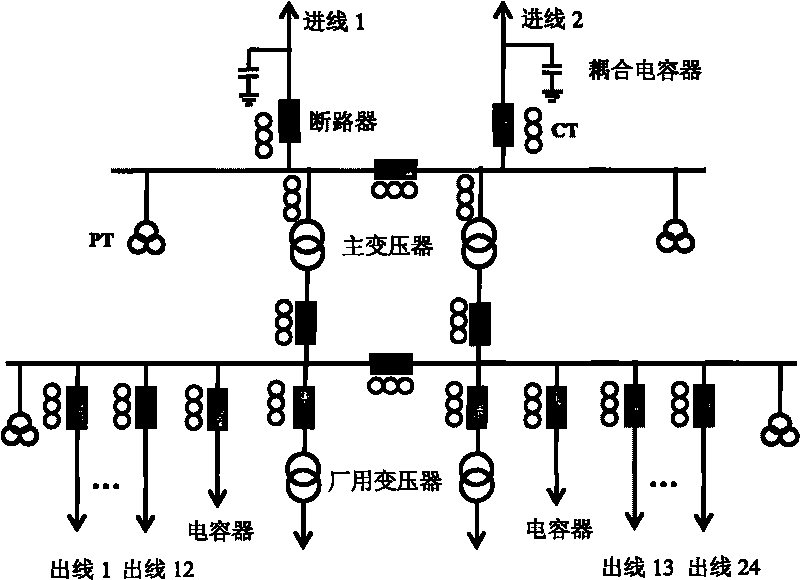

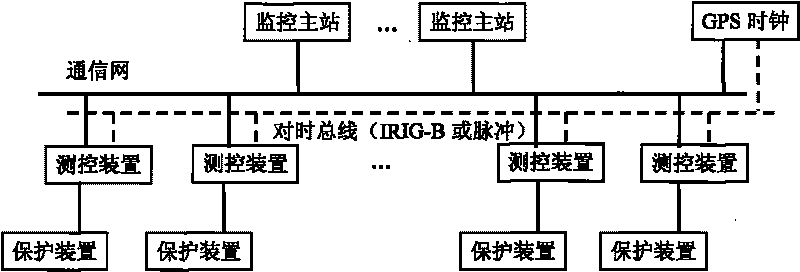

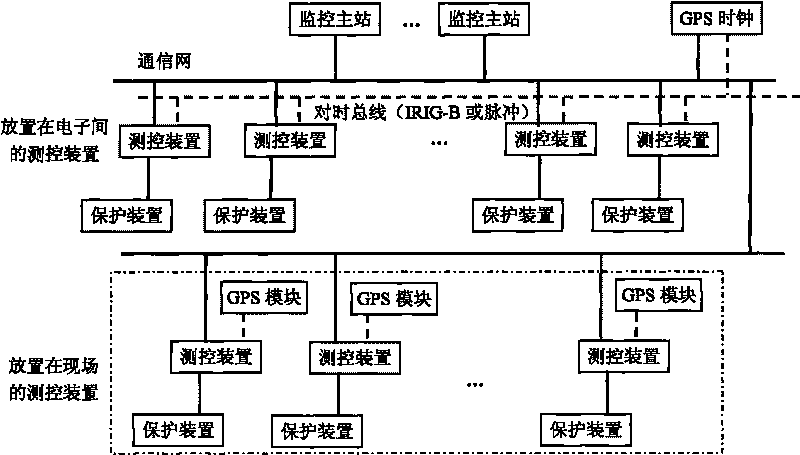

[0062] by figure 1 The 110kV substation shown is taken as an example. N sets of monitoring master stations are set in the main control room of the substation, and the addresses of the master stations are set as F1H, F2H, ..., FnH. Configure PMUs at the two main transformers, 110kV incoming circuit breaker, bus tie circuit breaker, 10kV outgoing line circuit breaker, 10kV bus tie circuit breaker, and 10kV factory transformer. Configure IPMU at 110kV PT, 110kV incoming line CT, 110kV incoming line surge arrester, 10kV PT, and 10kV incoming line CT. A2H, ..., sorted in turn. PMU and IPMU are divided into two groups of 110kV and 10kV according to the voltage level. Each of the two groups is provided with a bay layer communication unit BCOM, and the addresses of the two BCOMs are FDH and FEH respectively. In the 110kV group, a PMU of a 110kV main transformer sends voltage synchronized phasors to the IPMU of the 110kV group, and in the 10kV group, a PMU of a 10kV plant transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com