Novel direct-current converter valve test unit

A technology for a DC converter valve and a display unit, which is applied in the field of power systems, can solve problems such as damage to components and equipment of the converter valve, and achieve the effect of simplifying circuit design and facilitating analysis and problem finding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is realized by adopting the following technical solutions: the DC converter valve test unit mainly completes the following tests:

[0053] 1) Converter valve impedance test;

[0054] 2) GU energy storage time test;

[0055] 3) Thyristor low voltage trigger test;

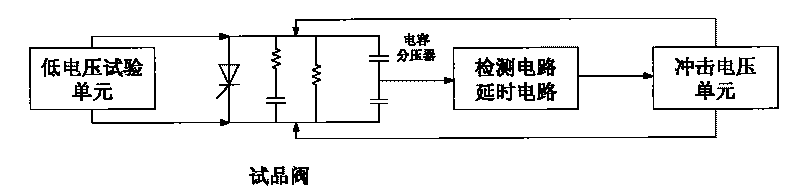

[0056] 4) Thyristor reverse recovery period protection test;

[0057] 5) Endurance test after the reverse recovery period of the thyristor;

[0058] 6) Thyristor positive polarity dv / dt withstand test;

[0059] 7) Thyristor forward overvoltage and dv / dt protection test;

[0060] 8) Negative polarity dv / dt tolerance test;

[0061] 9) Low pressure trigger test after the test;

[0062] 10) Impedance test after the test.

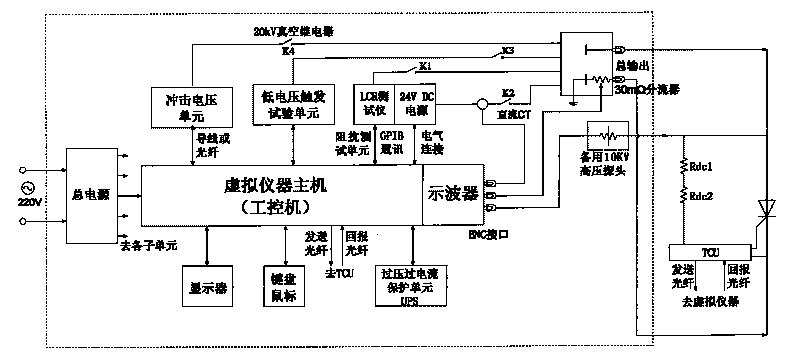

[0063] The principle block diagram of the valve test unit is attached figure 1 As shown, the DC converter valve test device includes industrial computer, impulse voltage unit, low voltage trigger test unit, impedance tester LCR, 24V power supply, valve voltage and cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com