Disk cutter geological adaptability design method based on CAD/CAE and optimal design

A disc-shaped hob and design method technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of disc-shaped hob damage, low rock breaking efficiency, unreasonable size, etc., to reduce energy consumption, The effect of shortening the development cycle and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

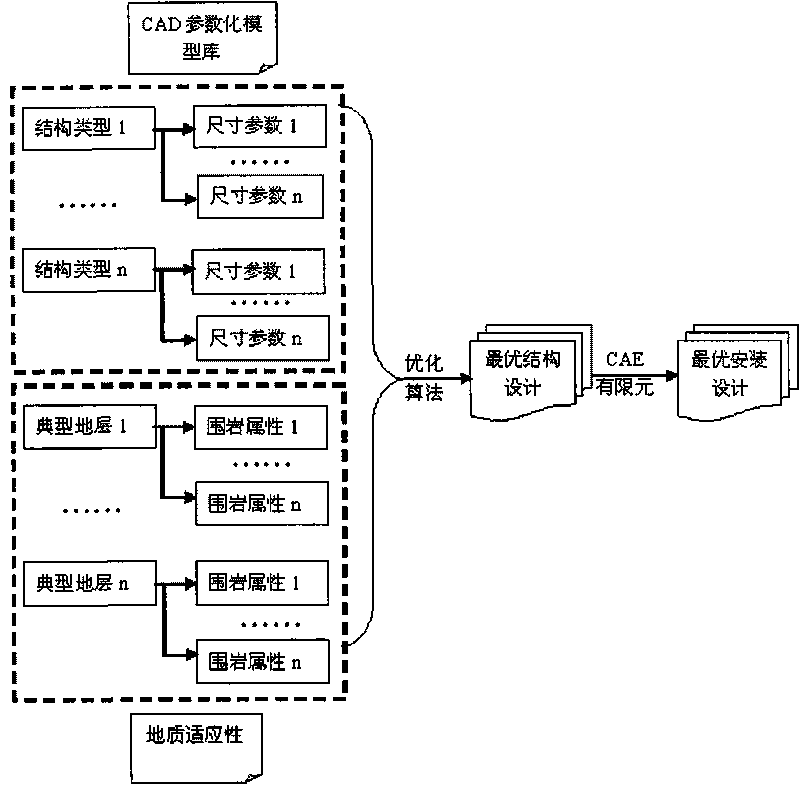

[0023] 1. Establishment of CAD parametric model library of disc hob

[0024] First, collect and summarize the existing disc hob drawings at home and abroad, determine the main structure types of the disc hob model library to be established, and take the knife ring blade structure parameters blade angle, blade width, and transition arc radius as the basic geometric parameters. And when considering the installation design of the disc hob, the above basic parameters also include the interference value between the cutter ring and the cutter body, the basic parameters are used as design variables, and the disc hob is established by making different changes to the basic parameters. CAD parametric solid model library.

[0025] 2. Multi-objective optimization model establishment

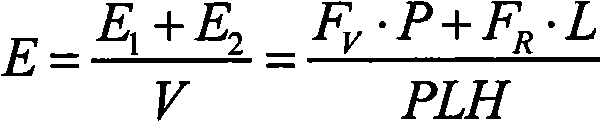

[0026] According to the different parameters related to compressive / tensile strength and surrounding rock properties under confining pressure, a variety of typical strata are selected, and on the basis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com