Clamping device for precalibration of COG chip

A technology for clamping devices and chips, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as affecting chip bonding accuracy, different chip directions and positions, and unstable chip positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

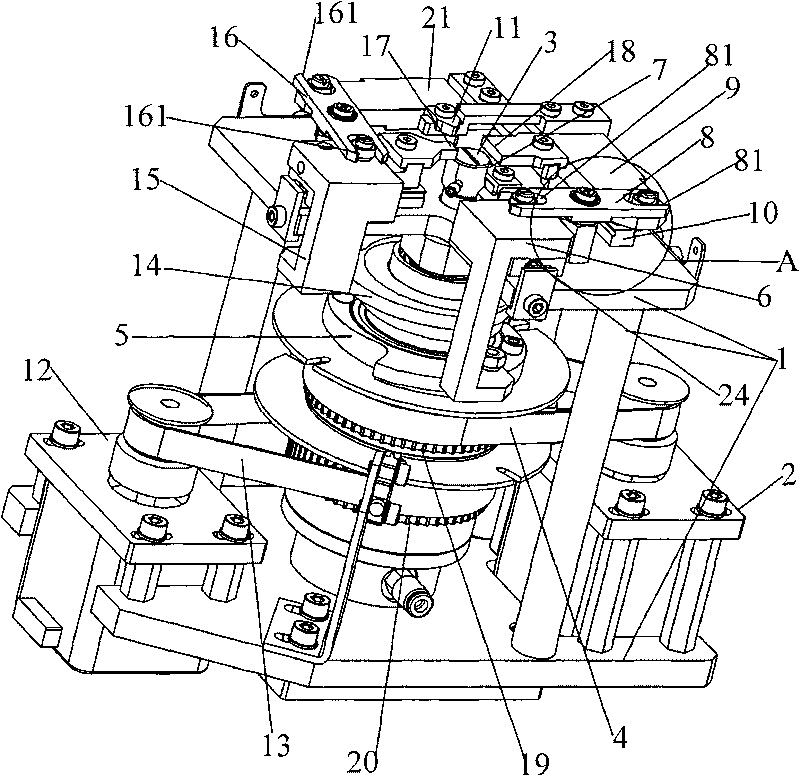

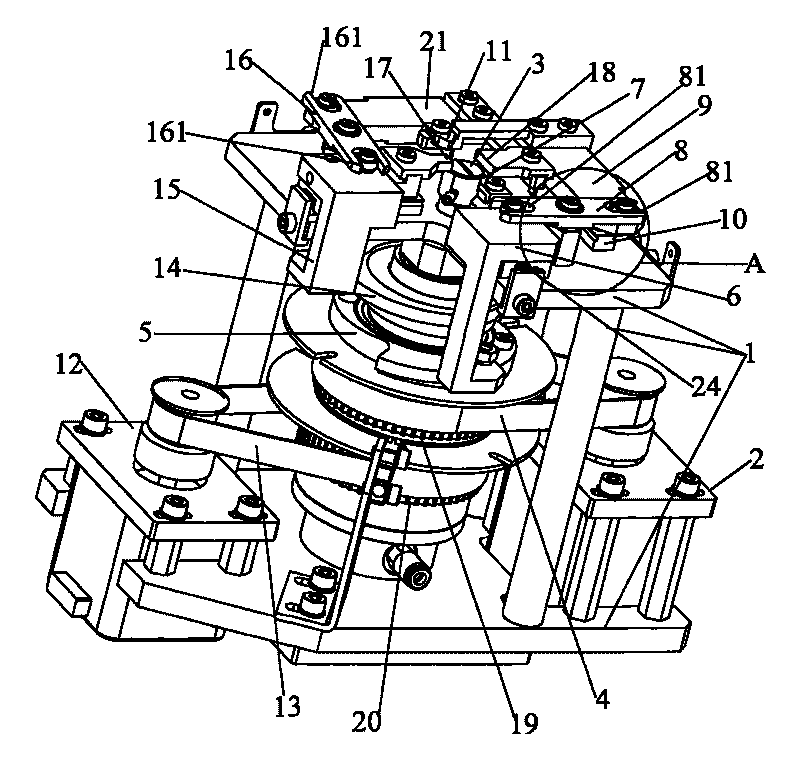

[0022] Such as figure 1 and figure 2 As shown, the present invention provides an embodiment of a COG chip pre-calibration clamping device.

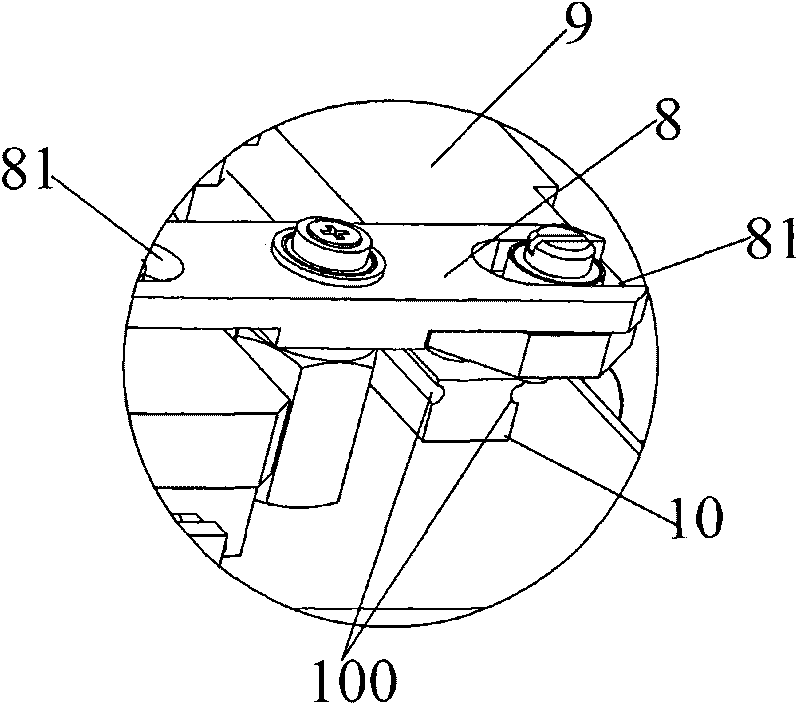

[0023] The COG chip pre-calibration clamping device includes: a base 1, a first motor 2 fixed on the base 1 and a fixing device 3 for placing the calibration chip, and the first motor 2 passes through the first transmission belt 4. Connect with the first rotating wheel 19 fixed on the first rotating shaft (not shown in the drawings), the first rotating shaft is fixed to the base 1, the first rotating shaft is provided with a first cam 5, and the first cam The outer side of the 5 is provided with a first transmission rod 6 in close contact, the first transmission rod 6 provided with the first correction block 7 is slidably connected to the base 1, and the first transmission rod 6 and the base 1 are provided with a There is a first spring 22, the first transmission rod 6 is connected with the first slider 9 through the first transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com