Ship propulsion DC motor

A DC motor and ship technology, applied in ship propulsion, propulsion engine, propulsion components, etc., can solve the problems of poor mobility, heavy weight, high energy consumption, and achieve the effects of strong overload capacity, safe and reliable use, and low failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

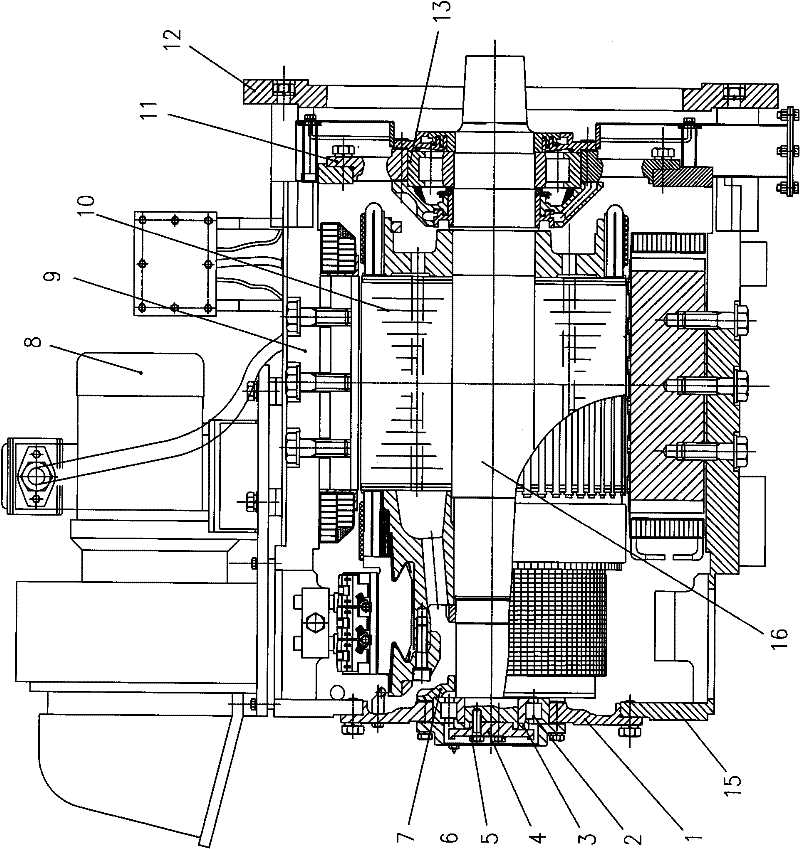

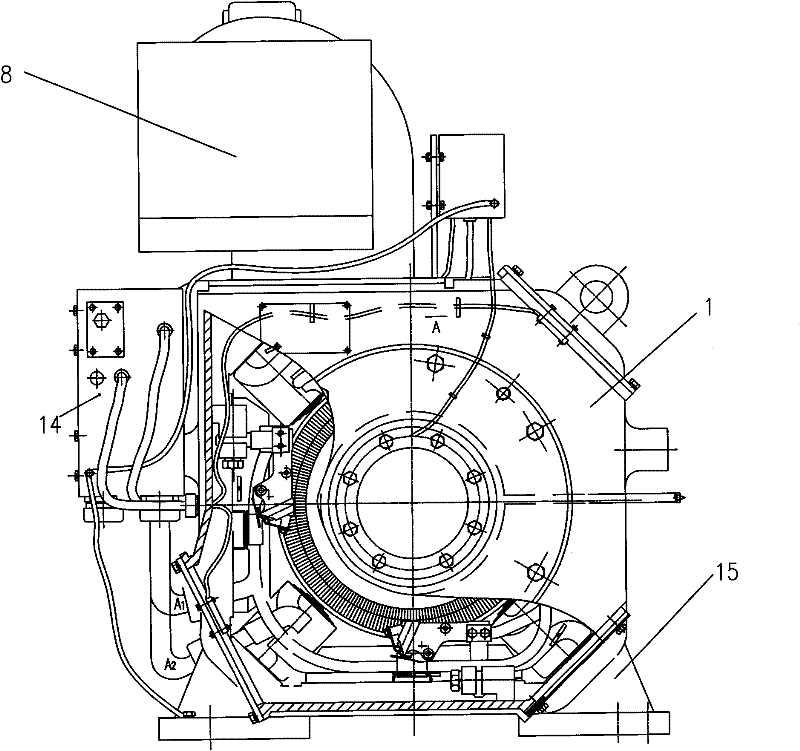

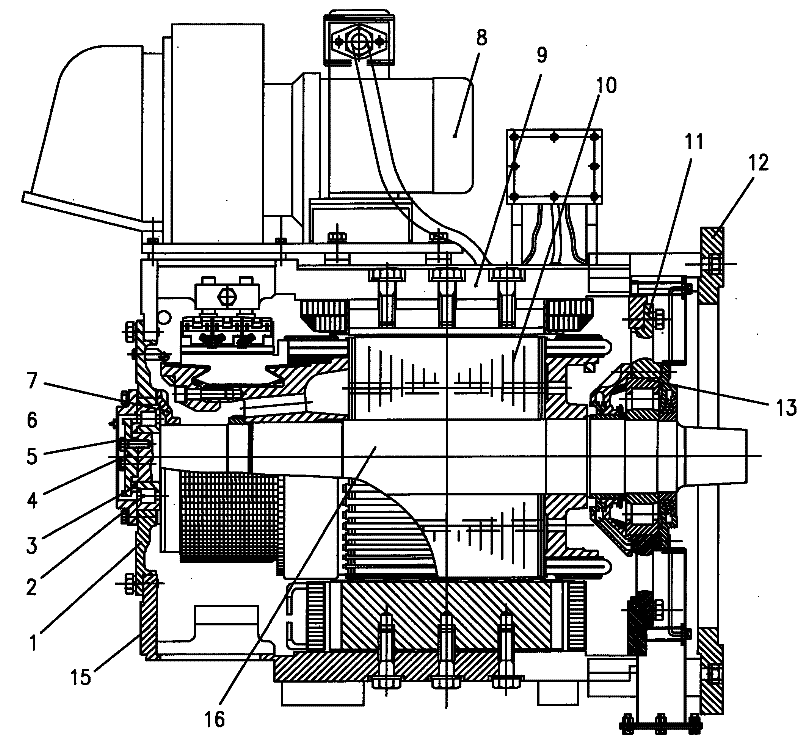

[0010] Main parts of the motor: 1. Left end cover, 2. First bearing, 3. Annular angle ring, 4. Press plate, 5. Galvanized steel hexagon bolt, 6. Brake washer, 7. Bearing inner cover, 8. Fan, 9. Stator, 10. Rotor, 11. Right end cover, 12. Flange, 13. Second bearing, 14. Outlet box, 15. Machine base, 16. Main shaft.

[0011] As shown in the figure: the ship propulsion DC motor includes a left end cover 1 arranged at the left end of the machine base 15, and a right end cover 11 arranged at the right end of the machine base 15, and the left end of the main shaft 16 is installed on the left end cover 1 with the first bearing 2 Above, the right end of the main shaft 16 is installed on the right end cover 11 using the second bearing 13; and, the right end of the main shaft 16 protrudes from the right end cover 11 to form a shaft extension end; the rotor 10 is installed on a section of the main shaft 16 located at the base 15 , the stator 9 is arranged on the inner wall of the base 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com