a wind generator

A technology for wind power generators and power generation modules, which is applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of high temperature of generators and affect the use of generators, and achieve the effect of high magnetic field density, high uniformity, and low start-up wind force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

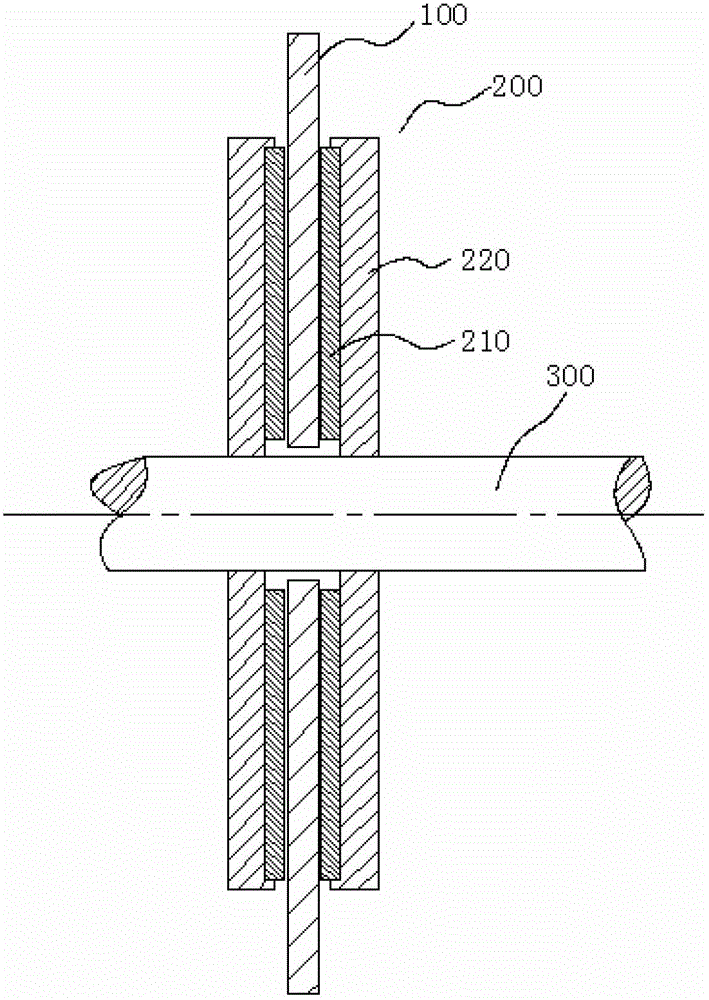

[0028] see figure 1 , a wind power generator, including a coil assembly 100, a magnetic steel assembly 200, a rotating shaft 300 and an impeller (not shown in the figure), and both sides of the coil assembly 100 are provided with a magnetic steel assembly 200.

[0029] see Figure 4 , the coil assembly 100 is disc-shaped, and the disc-shaped coil assembly 100 is provided with a wire 110 for cutting magnetic lines of force. In one preferred embodiment of the present invention, the coil assembly 100 is a PCB, and the two sides of the PCB are both A circuit is etched, and for a general generator, the coil assembly 100 can be an ordinary electromagnetic wire circuit.

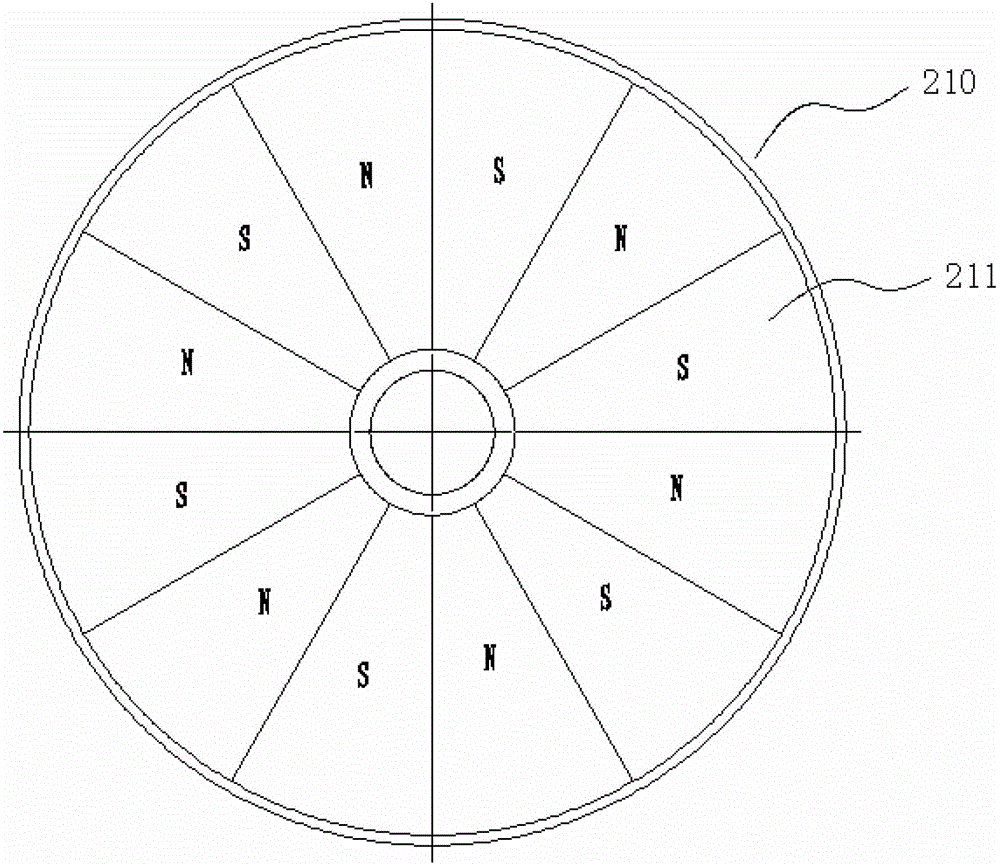

[0030] see figure 1 and image 3 The magnetic steel assembly 200 includes a magnetic steel 210 and a magnetic yoke 220. Both the magnetic steel 210 and the magnetic yoke 220 are disc-shaped. The magnetic steel 210 can be a piece of magnetic steel with multi-pole magnetization, or several pieces of magnetic steel ...

Embodiment 2

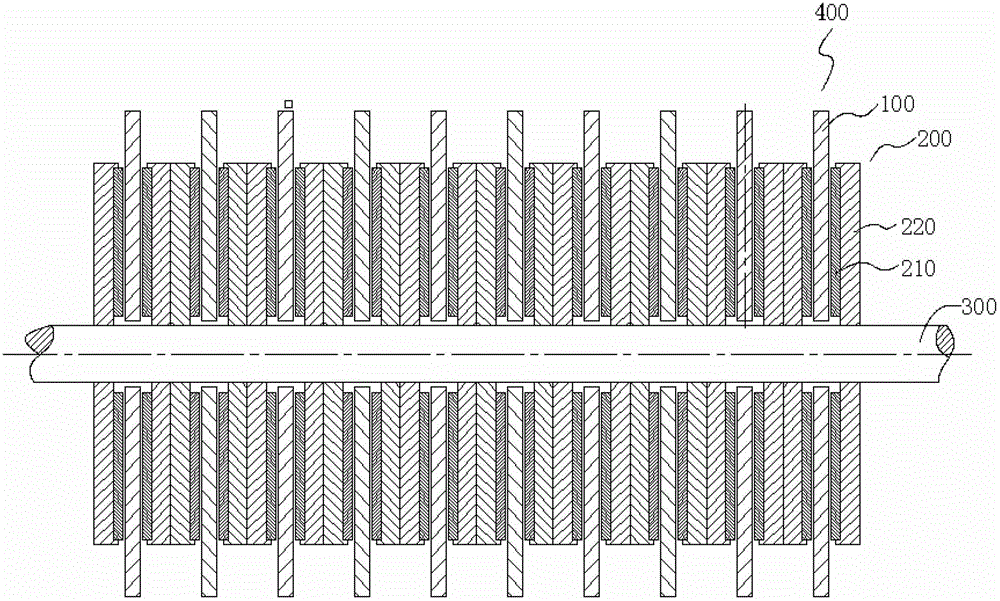

[0038] see figure 1 , a wind generator, including a coil assembly 100, a magnetic steel assembly 200, a rotating shaft 300 and an impeller (not shown in the figure), and both sides of the coil assembly 100 are provided with a magnetic steel assembly 200. And in this embodiment, the wind power generator includes more than two coil assemblies 100, the number of magnetic steel assemblies 200 is twice that of the coil assemblies 100, one coil assembly 100 and the magnetic steel assemblies 200 on both sides constitute a power generation module 400 , the power generation module 400 and the power generation module 400 are connected to each other.

[0039] see Figure 4 , the coil assembly 100 is disc-shaped, and a circuit 110 for cutting magnetic lines of force is provided on the disc-shaped coil assembly 100. In one of the preferred embodiments of the present invention, the coil assembly 100 is a PCB board, and both sides of the PCB board are The circuit is etched, and for a typical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com