Yarn tuft transfer system

A technology for conveying systems and yarns, applied in flannelette looms, weaving, textiles and papermaking, etc., which can solve problems such as inability to provide positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

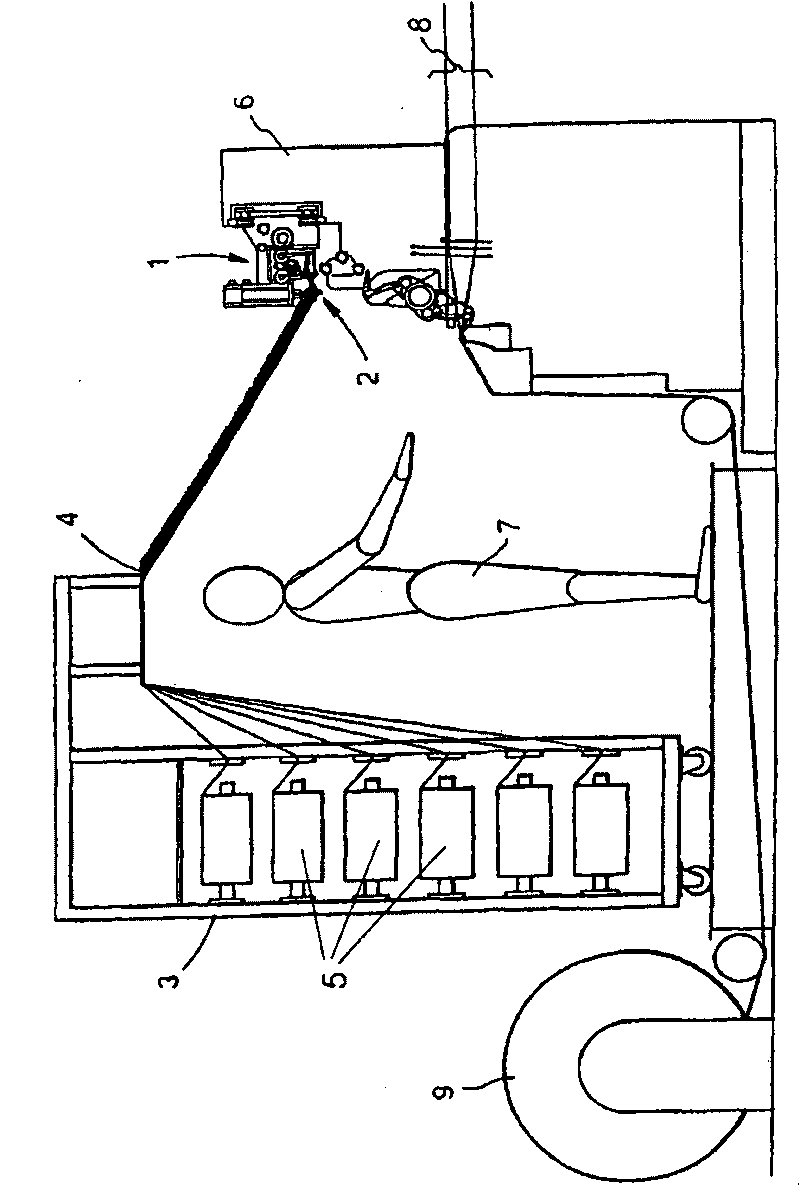

[0046] figure 1 with 2 A carpet loom in a preferred embodiment of the invention is shown in . The loom comprises one or more tuft forming units 1, each of which supplies yarn tufts to one or more different weaving points, and each unit comprises a yarn insertion device 2 for holding the yarn A movable creel 3 of the thread supply and a guide 4 for guiding the yarn from the supply 5 on the creel 3 to one or each tuft forming unit 1 . The creel 3 is located at the front of the loom and behind the weaver's station 7 . This is on the side of the loom opposite the warp beam (not shown) from which the warp yarns 8 are supplied. Alternatively, the creel 3 may be located above the rest of the loom 6 . The finished carpet is collected on roller 9.

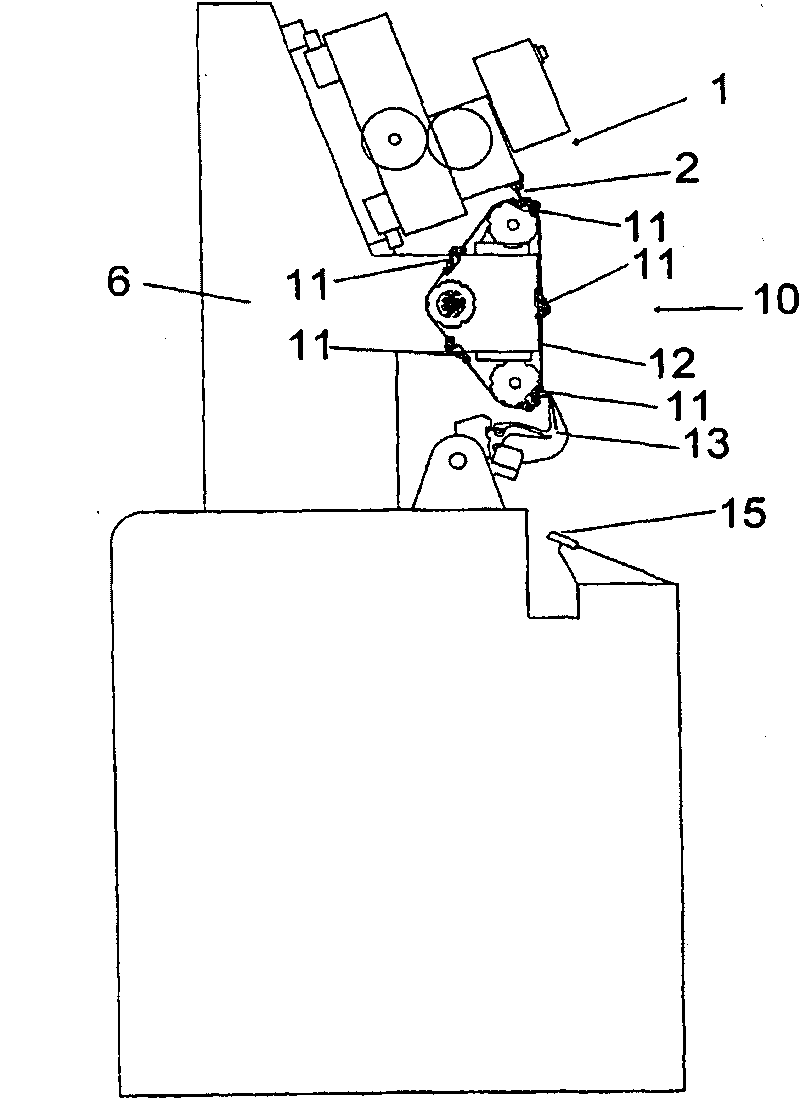

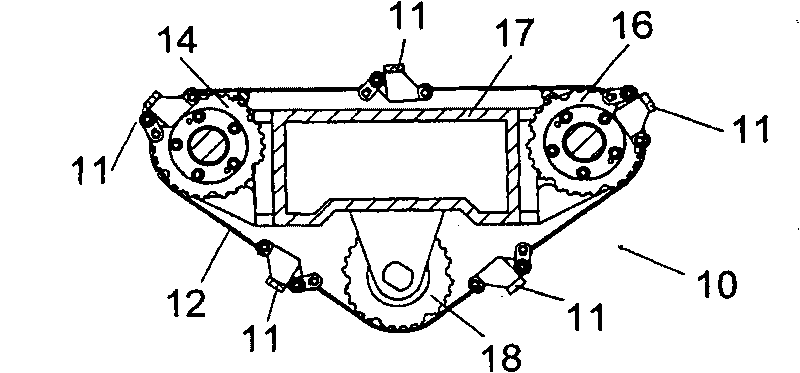

[0047] The loom comprises a yarn tuft delivery system 10 comprising five yarn tuft holders 11 mounted on a belt 12 . The belt 12 is arranged to move around a closed loop to sequentially feed each yarn tuft holder 11 to the yarn tuft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com