Construction method of large-volume original decorative large pier stud fair-faced concrete

A technology of fair-faced concrete and construction methods, applied in the direction of piers, columns, pillars, etc., can solve the problems of construction mechanization, low degree of standardization, and manual labor of fair-faced concrete, and achieve the effect of improving mechanization and standardization and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

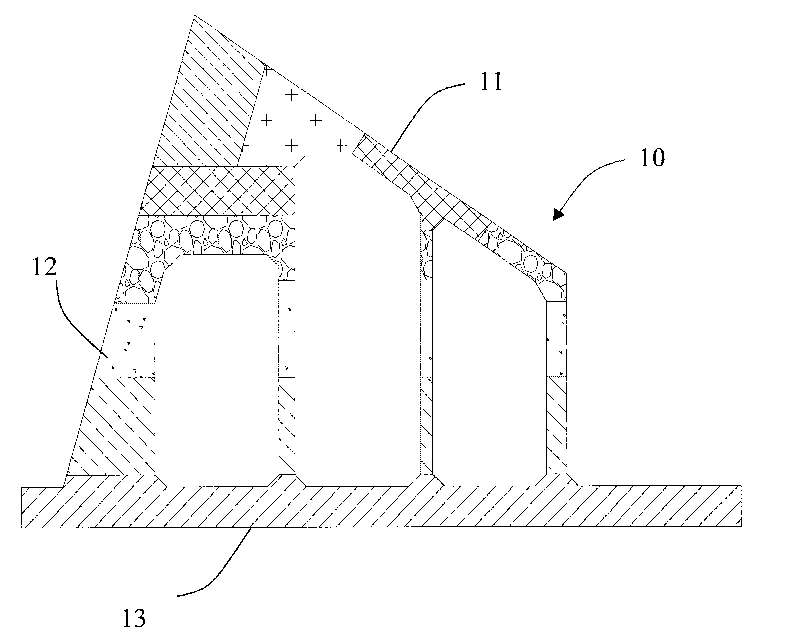

[0030] The present invention provides a large-volume puree-faced large pier column fair-faced concrete construction method, which is suitable for such as figure 1 The construction of the large-area, large-slope, and irregular large-volume puree-faced pier column 10 fair-faced concrete includes the following steps:

[0031] Build large pier column steel support; during construction, ensure that the rooting position of the steel bar is accurate, the steel bar should be corrected accurately at the bottom, and find out the main bar row spacing, and at the same time avoid the position of the bolt hole through the wall when the formwork is supported, and then ensure the position of the main bar is accurate When the steel bar is set out, the elongation of the steel bar in the bending process must be fully considered, not only to meet the anchorage length, but also to prevent the corners and intersections from being partially exposed due to the bent steel bar top formwork, resulting in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com